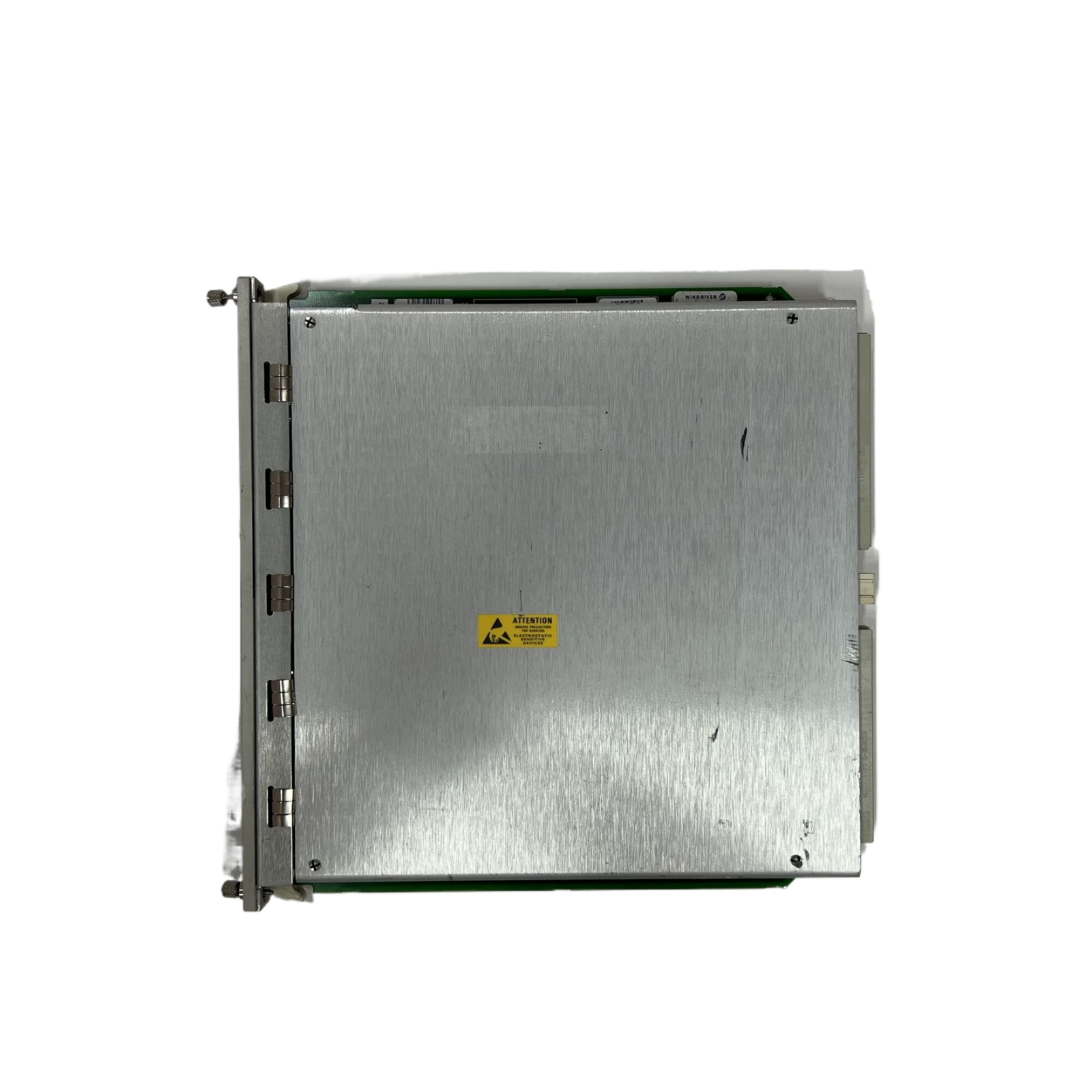

BENTLY Nevada 3500/33-01-01 16-Channel Relay Module for Industrial Control

Product Parameters:

The BENTLY Nevada 3500/33-01-01 is a state-of-the-art vibration monitoring system designed for critical machinery. It features advanced signal processing capabilities, a robust design for harsh environments, and a user-friendly interface for seamless operation. This model supports a wide range of sensors and provides real-time data analysis, ensuring optimal performance and reliability in various industrial applications.

Usage Scenarios:

Ideal for monitoring rotating equipment such as turbines, pumps, and compressors, the 3500/33-01-01 is essential for predictive maintenance. Its ability to detect early signs of wear and potential failures helps to minimize downtime and maintenance costs, making it a vital tool for industries such as oil and gas, power generation, and manufacturing.

Related Models:

The BENTLY Nevada 3500/33-01-01 is part of a comprehensive range of models, including BENTLY 3500/20 125744-02, BENTLY 3500/45 176449-04, BENTLY 3500/50, BENTLY 3500/40M, BENTLY 3500/92, BENTLY 3500/42M, BENTLY 3500/25, BENTLY 3500/34, BENTLY 3500/77M, and BENTLY 3500/93 P/N:135785-02.

Comparison with Other Models:

Compared to other models in the BENTLY Nevada series, the 3500/33-01-01 offers enhanced vibration monitoring capabilities. While models like the 3500/20 focus on basic parameters, the 3500/33-01-01 provides comprehensive diagnostics, making it more suitable for complex applications requiring detailed analysis and reporting. This makes it an excellent choice for facilities looking to elevate their predictive maintenance strategies.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada 3500/33-01-01 is a state-of-the-art vibration monitoring system designed for critical machinery. It features advanced signal processing capabilities, a robust design for harsh environments, and a user-friendly interface for seamless operation. This model supports a wide range of sensors and provides real-time data analysis, ensuring optimal performance and reliability in various industrial applications.

Usage Scenarios:

Ideal for monitoring rotating equipment such as turbines, pumps, and compressors, the 3500/33-01-01 is essential for predictive maintenance. Its ability to detect early signs of wear and potential failures helps to minimize downtime and maintenance costs, making it a vital tool for industries such as oil and gas, power generation, and manufacturing.

Related Models:

The BENTLY Nevada 3500/33-01-01 is part of a comprehensive range of models, including BENTLY 3500/20 125744-02, BENTLY 3500/45 176449-04, BENTLY 3500/50, BENTLY 3500/40M, BENTLY 3500/92, BENTLY 3500/42M, BENTLY 3500/25, BENTLY 3500/34, BENTLY 3500/77M, and BENTLY 3500/93 P/N:135785-02.

Comparison with Other Models:

Compared to other models in the BENTLY Nevada series, the 3500/33-01-01 offers enhanced vibration monitoring capabilities. While models like the 3500/20 focus on basic parameters, the 3500/33-01-01 provides comprehensive diagnostics, making it more suitable for complex applications requiring detailed analysis and reporting. This makes it an excellent choice for facilities looking to elevate their predictive maintenance strategies.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.