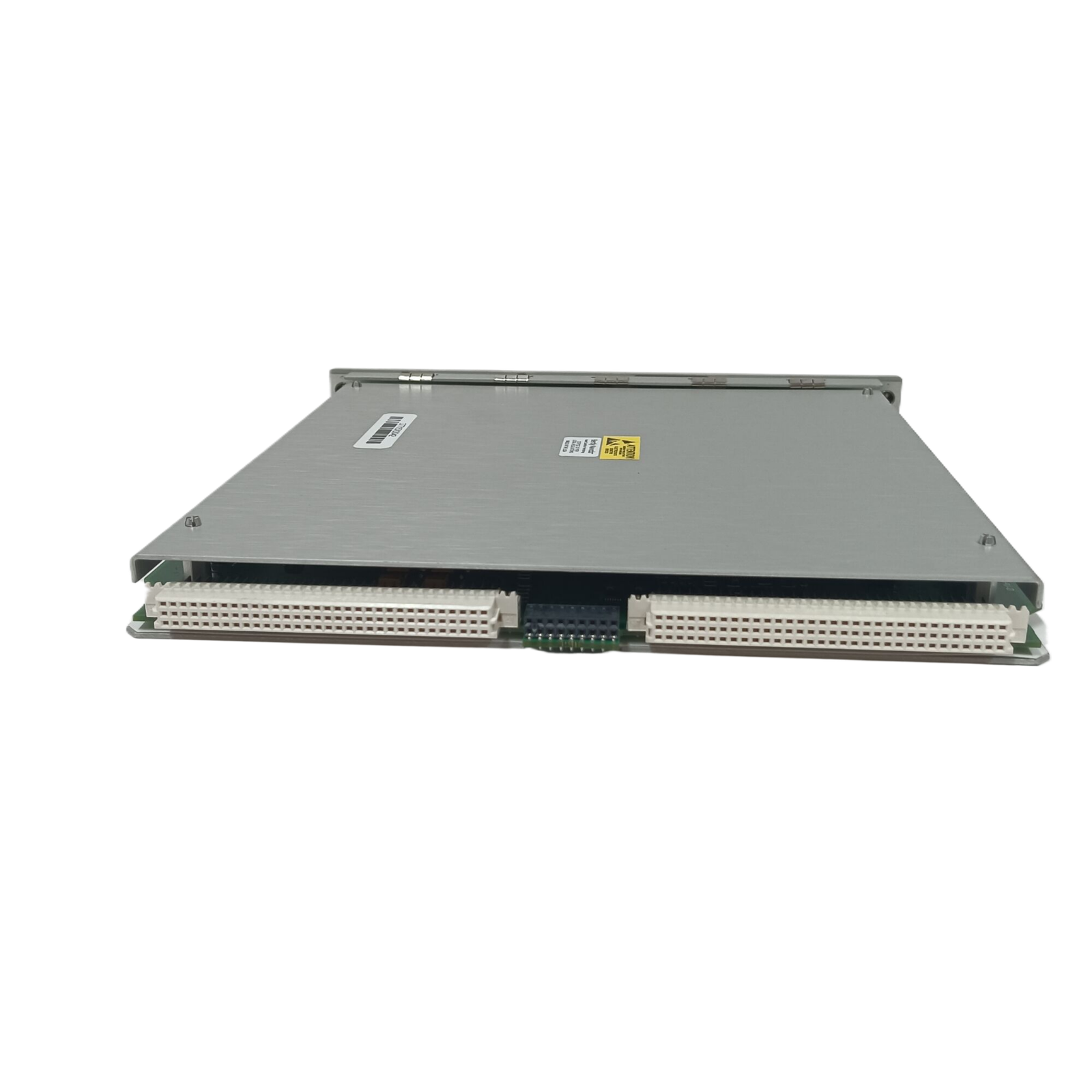

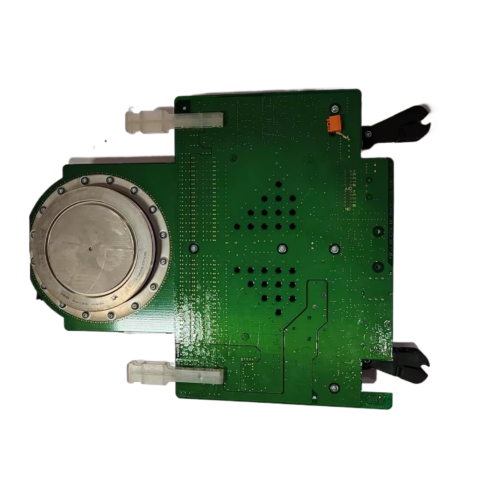

BENTLY 330102-00-60-05-01-CN Rapid Delivery Time for Industrial Control Solutions

Product Parameters:

The BENTLY 330102-00-60-05-01-CN is a high-performance vibration monitoring system designed for industrial applications. This model features advanced signal processing capabilities, ensuring accurate analysis of machinery conditions. With robust construction, it operates effectively in challenging environments, providing reliable data for maintenance planning.

Usage Scenarios:

Ideal for rotating equipment, the BENTLY 330102-00-60-05-01-CN is essential for predictive maintenance in power plants, oil and gas facilities, and manufacturing lines. It helps detect imbalances, misalignments, and bearing wear, minimizing downtime and enhancing operational efficiency.

Related Models:

This model is part of BENTLY’s extensive range, including BENTLY 3500/20 125744-02, BENTLY 3500/45 176449-04, BENTLY 3500/34, BENTLY 3500/50, and BENTLY Nevada. Other relevant models include BENTLY 330500-00-00, BENTLY 3500/92, BENTLY 330104-00-25-10-02-00, and BENTLY 3500/72M.

Comparison with Other Models:

Compared to models like the BENTLY 3500/40M, the 330102-00-60-05-01-CN offers enhanced sensitivity and broader application versatility. While both provide reliable monitoring, the 330102 excels in environments requiring stringent performance standards, making it a preferred choice for critical machinery.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY 330102-00-60-05-01-CN is a high-performance vibration monitoring system designed for industrial applications. This model features advanced signal processing capabilities, ensuring accurate analysis of machinery conditions. With robust construction, it operates effectively in challenging environments, providing reliable data for maintenance planning.

Usage Scenarios:

Ideal for rotating equipment, the BENTLY 330102-00-60-05-01-CN is essential for predictive maintenance in power plants, oil and gas facilities, and manufacturing lines. It helps detect imbalances, misalignments, and bearing wear, minimizing downtime and enhancing operational efficiency.

Related Models:

This model is part of BENTLY’s extensive range, including BENTLY 3500/20 125744-02, BENTLY 3500/45 176449-04, BENTLY 3500/34, BENTLY 3500/50, and BENTLY Nevada. Other relevant models include BENTLY 330500-00-00, BENTLY 3500/92, BENTLY 330104-00-25-10-02-00, and BENTLY 3500/72M.

Comparison with Other Models:

Compared to models like the BENTLY 3500/40M, the 330102-00-60-05-01-CN offers enhanced sensitivity and broader application versatility. While both provide reliable monitoring, the 330102 excels in environments requiring stringent performance standards, making it a preferred choice for critical machinery.

The above parameters are for reference only. Please contact our technical team for precise selection.

-480x480.png)

-480x480.png)

-480x480.png)

-480x480.png)

-480x480.png)

-480x480.png)

There are no reviews yet.