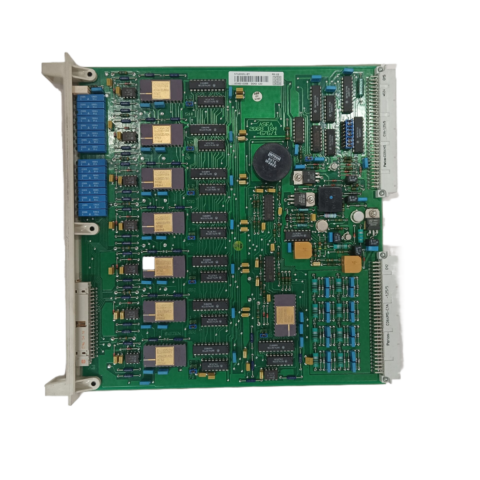

BENTLY 3500/34 Industrial Control Module

Product Parameters:

The BENTLY 3500/34 is a state-of-the-art monitoring system designed to provide real-time data on machinery health and performance. Featuring advanced vibration analysis capabilities, it supports up to 16 channels for comprehensive monitoring, ensuring high accuracy and reliability. The unit operates within a temperature range of -40°C to +70°C and meets rigorous industrial standards for durability.

Usage Scenarios:

Ideal for industries such as oil and gas, power generation, and manufacturing, the BENTLY 3500/34 is perfect for applications requiring continuous monitoring of rotating equipment. Its robust design allows for deployment in harsh environments, providing critical insights that enhance operational efficiency and reduce downtime.

Related Models:

Explore other models in the BENTLY range, including the 3500/20, 3500/40M, 3500/50, 3500/53, 3500/22M, 3500/15, 3500/45, 3500/92, 3500/42M, and 3500/25. Each model is engineered for specific applications, offering unique features that cater to various monitoring needs.

Comparison with Other Models:

Compared to the BENTLY 3500/20, the 3500/34 offers enhanced channel support and advanced vibration analysis. While the 3500/50 focuses on temperature monitoring, the 3500/34 excels in comprehensive vibration diagnostics, making it a superior choice for machinery health assessment.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY 3500/34 is a state-of-the-art monitoring system designed to provide real-time data on machinery health and performance. Featuring advanced vibration analysis capabilities, it supports up to 16 channels for comprehensive monitoring, ensuring high accuracy and reliability. The unit operates within a temperature range of -40°C to +70°C and meets rigorous industrial standards for durability.

Usage Scenarios:

Ideal for industries such as oil and gas, power generation, and manufacturing, the BENTLY 3500/34 is perfect for applications requiring continuous monitoring of rotating equipment. Its robust design allows for deployment in harsh environments, providing critical insights that enhance operational efficiency and reduce downtime.

Related Models:

Explore other models in the BENTLY range, including the 3500/20, 3500/40M, 3500/50, 3500/53, 3500/22M, 3500/15, 3500/45, 3500/92, 3500/42M, and 3500/25. Each model is engineered for specific applications, offering unique features that cater to various monitoring needs.

Comparison with Other Models:

Compared to the BENTLY 3500/20, the 3500/34 offers enhanced channel support and advanced vibration analysis. While the 3500/50 focuses on temperature monitoring, the 3500/34 excels in comprehensive vibration diagnostics, making it a superior choice for machinery health assessment.

The above parameters are for reference only. Please contact our technical team for precise selection.

-480x480.png)

-480x480.png)

-480x480.png)

-480x480.png)

There are no reviews yet.