Woodward easYgen LS-6XT Multi-Breaker control

Basic Information

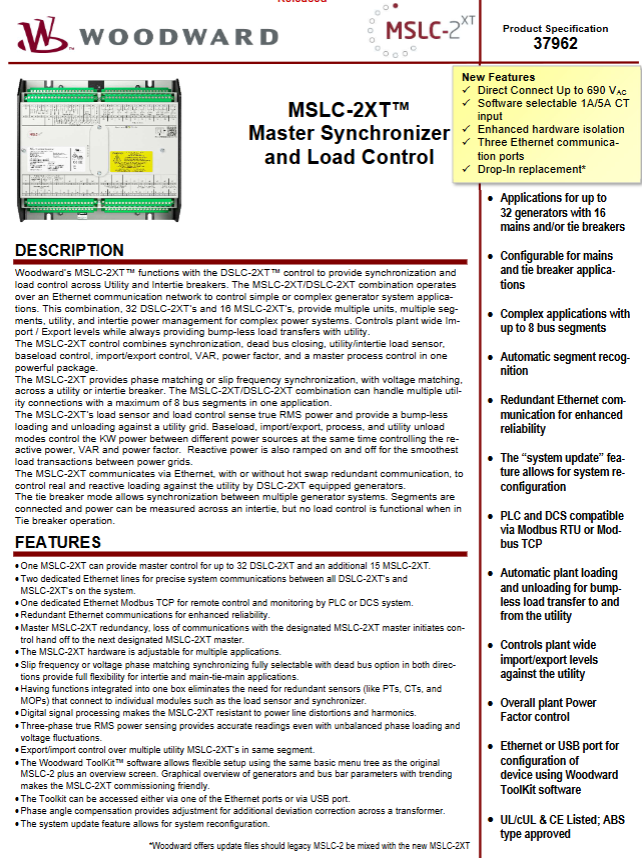

Product model easyYgen LS-6XT series (circuit breaker controller)

High end circuit breaker control with core positioning for complex power management scenarios, integrating synchronization, protection, and communication functions

Target users: OEM switchgear manufacturers, generator set installers, and system integrators

Adapt to scenarios such as parallel operation of power grids, islanding operation, multi unit linkage, peak shaving, and import/export power control

Core hardware configuration and specifications

(1) Power supply and environmental parameters

Category specific specifications

Power input voltage range 8-40Vdc (supports 12/24VDC), maximum power consumption 22W

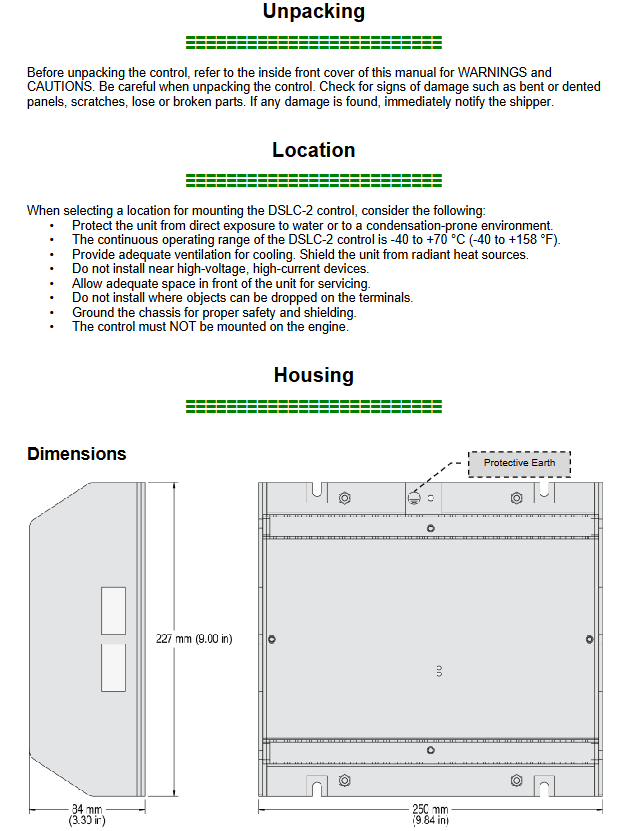

Working environment temperature -40 ° C~70 ° C, humidity 95%, no condensation

Storage environment temperature -40 ° C~80 ° C

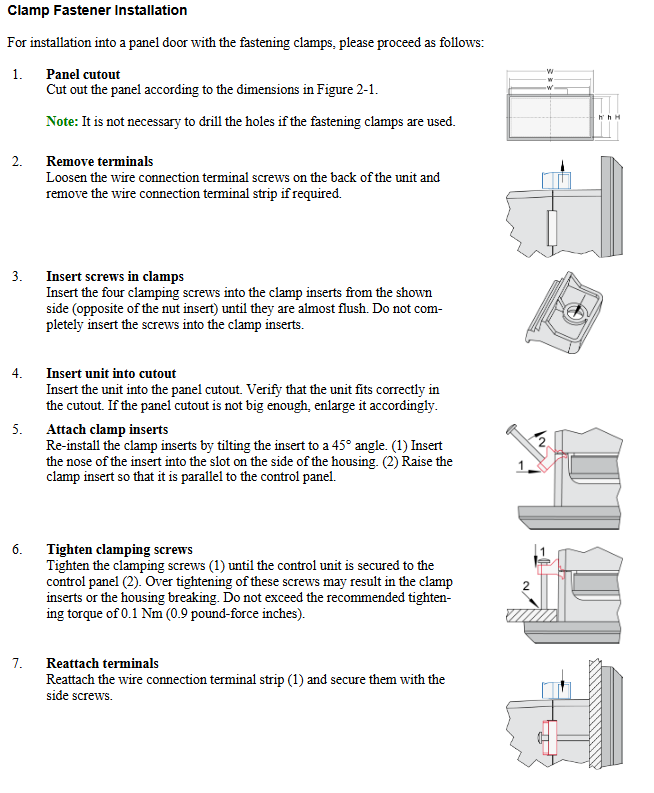

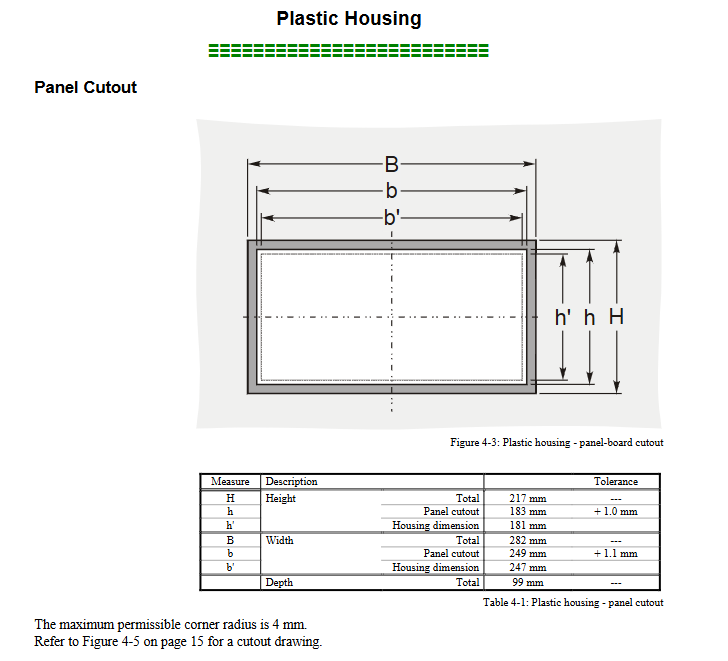

Structural specifications: Metal powder coated shell, size 250 (W) × 228 (H) × 50 (D) mm (P1 model), weight approximately 1.75kg, protection level IP20

Certification compliance CE, UL, cUL, LR (Lloyd’s Register), ABS (American Bureau of Shipping) certification

(2) Measurement and I/O interface

Interface type specification details

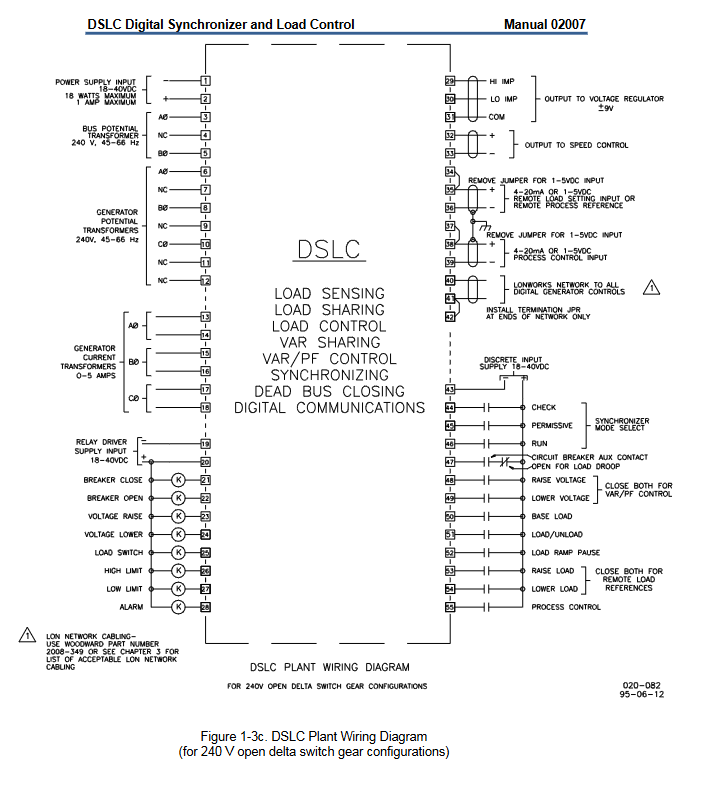

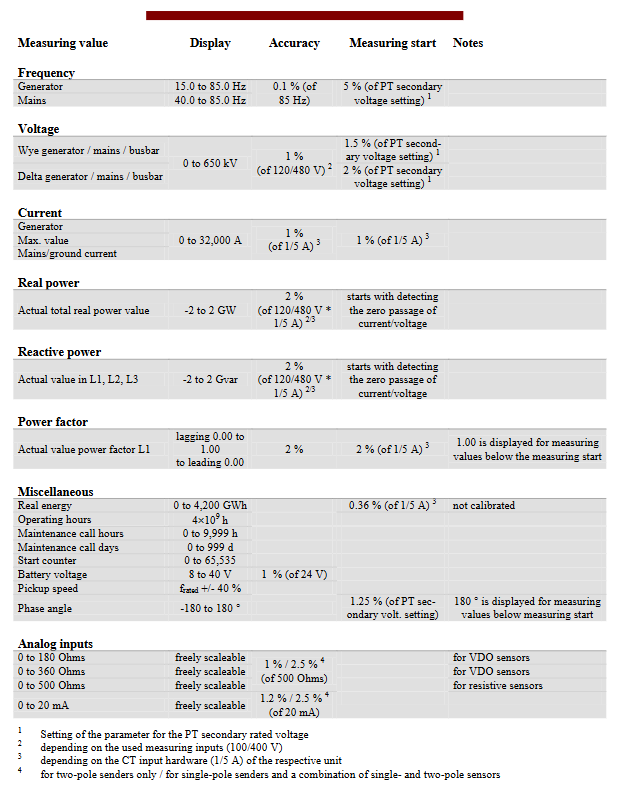

Voltage measurement supports independent measurement of system A, system B, and auxiliary voltage; Suitable for 100/400/600/690Vac; Measurement accuracy Class 0.5; Support 3Ph3W/3Ph4W/1Ph2W/1Ph3W wiring

Current measurement support system A and system B for current measurement; CT input 1A/5A software optional; The linear measurement range of System A is 3.0 × Irated, and System B is 1.5 × Irated; Measurement accuracy Class 0.5

Discrete Input (DI) 12 channel optically isolated input, voltage range 8-40Vdc, input resistance of approximately 20k Ω; supports IKD module expansion to 32 channels

Discrete Output (DO) 12 relay outputs, contact material AgNi, load 2A@250Vac /24Vdc; Support IKD module expansion to 32 channels

Analog input (AI) with 3 isolated inputs, supporting 0-1V/0-2000 Ω/0-20mA, with a resolution of 16 bits; Freely calibratable

Analog output (AO) with 2 isolated outputs, supporting ± 10V/± 20mA/PWM, with a resolution of 12 bits; AO # 1 insulation voltage 100Vac, AO # 2 reinforced insulation 300Vac

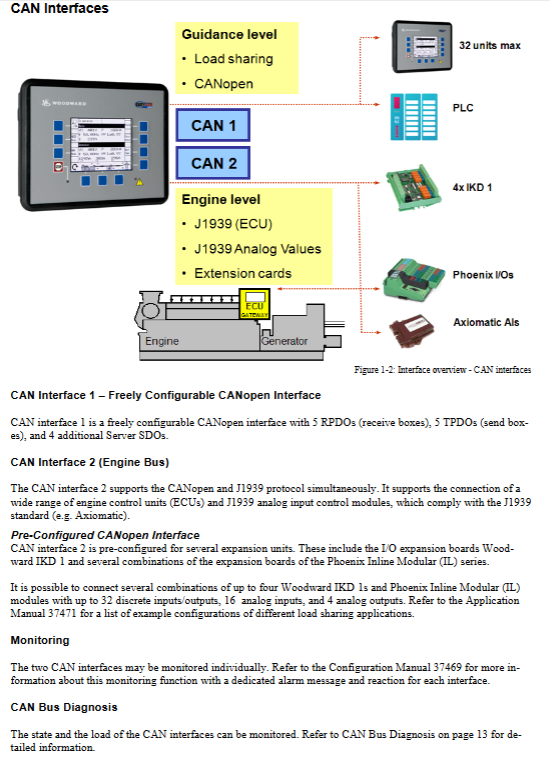

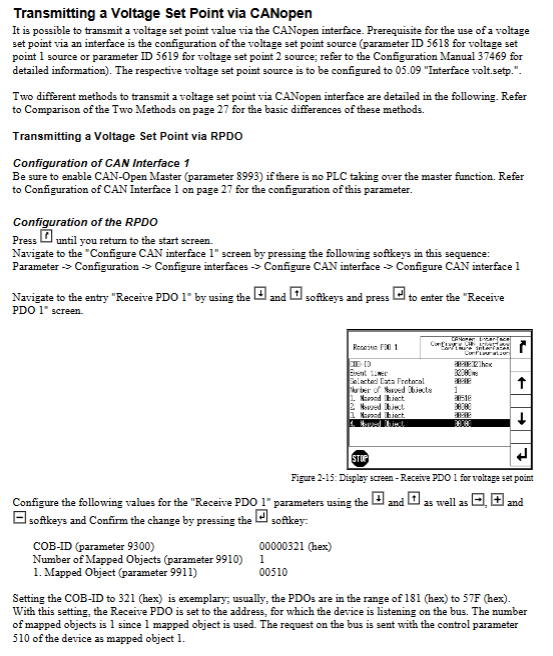

(3) Communication interface

Core parameters of communication type

Redundant communication supports CAN ETH and Eth ETH redundancy schemes to avoid single point failures

Ethernet 3 independent RJ-45 ports, supporting 10/100Base-T, used for remote control, visualization, and group controller linkage

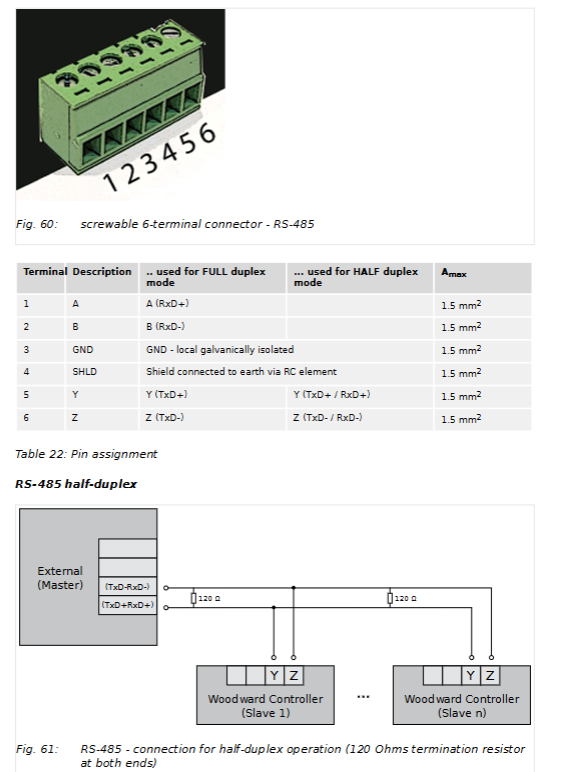

RS-485 supports Modbus RTU protocol for remote control and data exchange

CAN bus supports CANopen protocol for IKD module expansion I/O and device interconnection

USB for ToolKit software configuration and maintenance

Core functions and features

(1) Control and synchronization function

Circuit breaker control: Supports 1-2 circuit breakers (CBA/BBB), configurable closing/opening logic, supports pulse (<100ms) or continuous output

Load transfer mode: 4 options (Open Transition/Lost Transition/Interchange/Define Parallel), suitable for different power switching scenarios

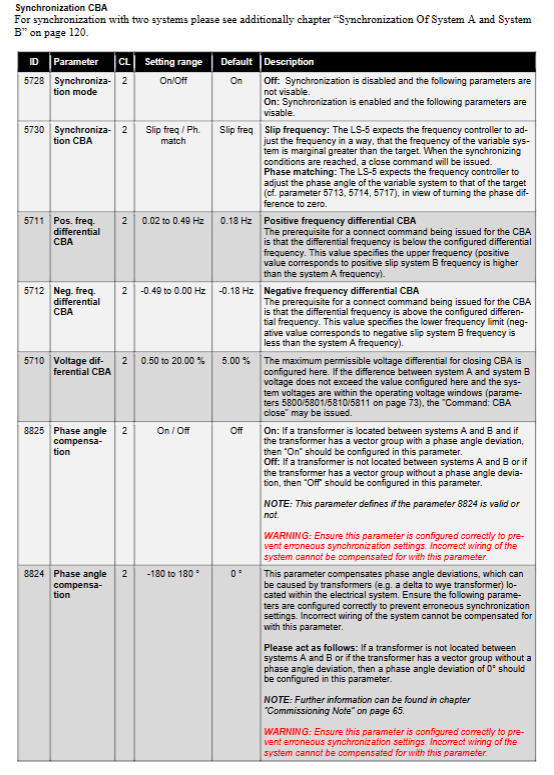

Synchronous grid connection: supports phase matching, slip frequency synchronization, and has voltage matching function; Support forward/reverse synchronization between the power grid and the unit group

Dead bus closure: automatically detects no voltage bus, safely closes circuit breaker after meeting conditions, supports multi device negotiation mechanism

(2) Measurement and protection functions

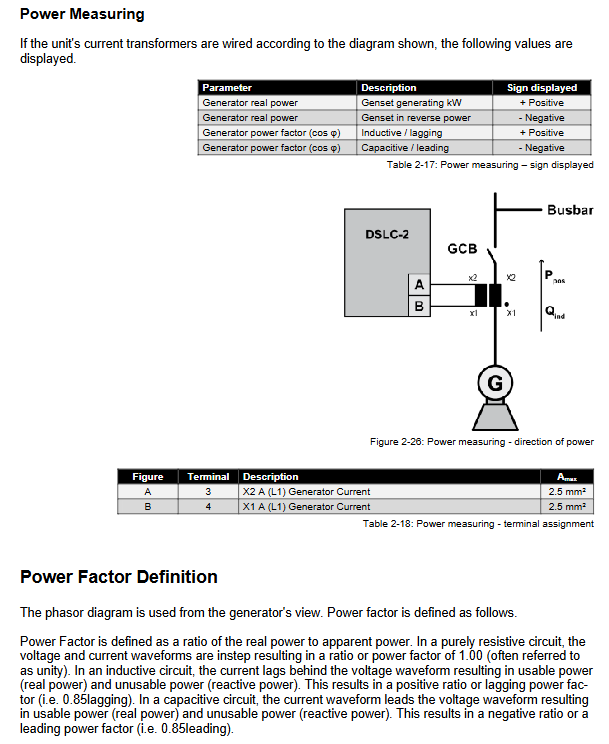

Power measurement: Class 1 accuracy, supports active/reactive power calculation, can access external sensor data

Built in protection: including ROCOF (rate of change), phase offset, flexible limit protection, etc., customizable protection logic

Monitoring range: key parameters such as voltage, current, frequency (30-85Hz), phase, power factor, etc

(3) Programming and Extension Features

LogicsManager: supports custom logic programming, associating I/O signals, alarm conditions, and control instructions

AnalogManager: Analog processing, supporting sensor curve calibration and custom conversion formulas

I/O Expansion: Connected to IKD module via CAN bus, expandable up to 32 DI/32 DO channels

Custom configuration: supports personalized configuration of HMI screen (RP-3000XT), alarm information, and logic rules

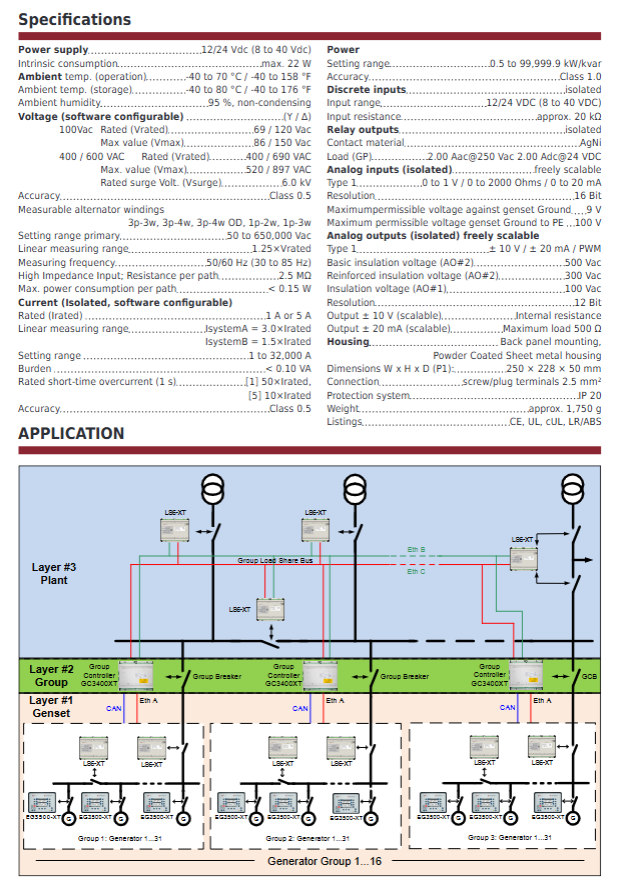

(4) System linkage and management

Scale support: up to 32 LS-6XT and 32 easyYgen-3400XT/3500XT linked; Or 64 LS-6XT units and 16 GC-3400XT units (with a maximum of 31 units per group) are linked together

Segmented control: supports load sharing management for 128 bus segments

Data synchronization: LS-6XT automatically synchronizes date and time with associated devices

Diagnostic function: Detailed communication diagnosis, visual monitoring of the status of all networked devices for easy troubleshooting