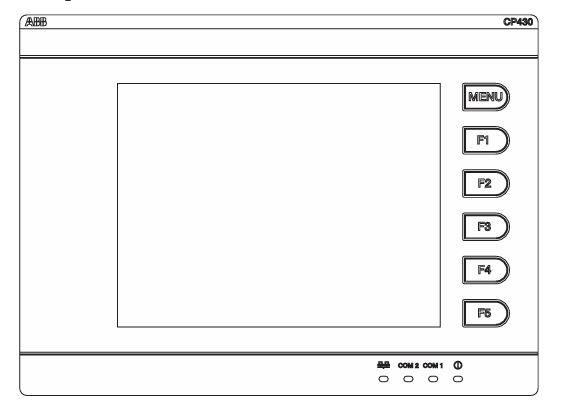

ABB CP430 Human Machine Interface (HMI)

Operation Equipment

Basic features: CP430 is a human-machine interface (HMI) equipped with a 5.7-inch STN LCD display, with IP65/NEMA4X protection level (indoor use only), CE certification, strong transient resistance, compact design, and easy connection with other devices for optimal performance.

Configuration tool: Use CP400Soft for application design, which is reliable, easy to use, and compatible with multiple models.

Safety precautions

Personnel Qualification: Only qualified personnel are allowed to install, operate, or maintain the equipment.

Installation environment: It needs to be installed on a flat surface, and the environment should meet the requirements of no high explosion risk, no strong magnetic field, no direct sunlight, and no drastic temperature changes. It is suitable for pollution level 2 environment and can be installed on the flat surface of Class 1 and Class 4X (indoor only) enclosures.

Power requirements: The input is 24V DC, and the power supply voltage needs to be within the range of 24V DC ± 15%, otherwise it may seriously damage the equipment, and the power supply needs to be checked regularly.

Grounding requirements: The grounding cable must be correctly grounded, otherwise it may be affected by noise. The cross-sectional area of the grounding cable should be at least 2mm ² (AWG 14), the grounding resistance should be less than 100 Ω (level 3), and the grounding cable must not be connected to the same grounding point as the power circuit.

Other precautions: Do not allow liquids, metal debris, etc. to enter the equipment; LCD display screens contain highly irritating substances in liquid, and contact with the skin or eyes requires timely treatment; ABB is not responsible for equipment modification or the use of non ABB specification components and accessories; Communication cables should be separated from power cables and only shielded cables should be used.

Installation instructions

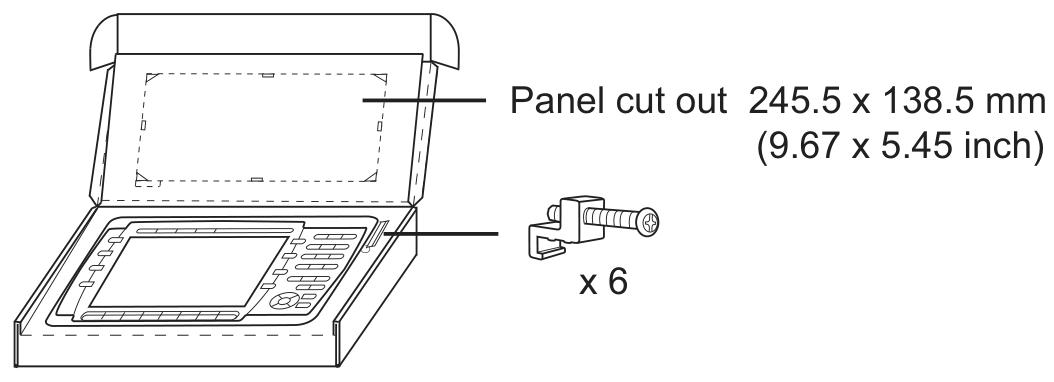

Packaging content

Includes CP430 operator terminal, 6 installation fasteners, power connector (connected to 24V DC power input), and installation and operation manual (1SBC159103M0202).

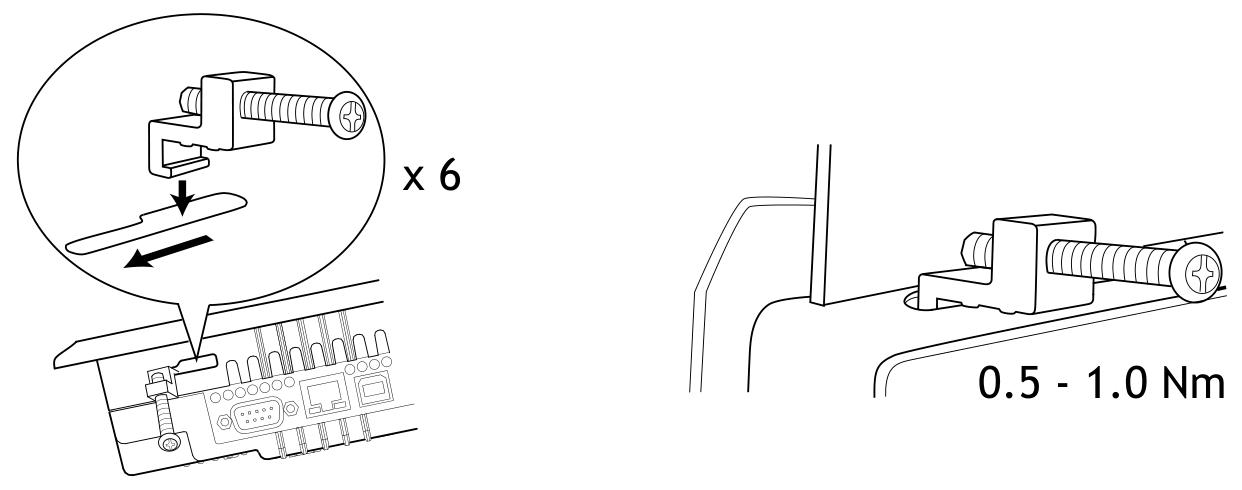

Installation steps

Drill holes on the control front panel according to the dimensions of 185.8 × 135.8mm.

Install the operator terminal into the opening, insert the fixture into the hole on the device, and tighten it to the front panel with screws, with a torque of 0.6~0.7 Nm (5.31-6.2 lb in).

The installation angle of the operator terminal should be within the range of 0 ° to 135 °.

Product specifications

General parameters (some main parameters)

Front panel size: 195.0 × 145.0 × 6.0mm.

Installation depth: 59.1mm.

Weight: ranging from 0.81 to 0.86kg.

Communication ports: COM1 (9-pin female connector, supporting RS232/RS485), some models have COM2 (25 pin female connector, supporting RS232/RS422/RS485); Some models have USB ports, CF card ports, and Ethernet ports.

Storage: 4MB Flash ROM, 16MB RAM, 512KB battery backup memory, 512KB data/recipe.

Display screen: Color TFT LCD (some models are monochrome STN LCD), 64K colors (some models are 16 blue tones), resolution of 320 × 240 pixels, CCFT backlight lifespan of approximately 50000-60000 hours at 25 ° C.

Power supply: 24V DC ± 15%, power consumption less than 20W.

Working environment: Temperature range of 0 ° C to+50 ° C, humidity range of 20-90% RH (non condensing).

Operating instructions

DIP switch settings

SW1, SW2, and SW9 are reserved.

SW3 and SW4 are used to set operating modes, such as running user applications, running aging test programs, etc.

SW5 is used to select the source of communication parameters, either from the operator terminal configuration screen or CP400Soft.

SW6 is used to set whether a password is required to start the operator terminal.

SW7 is used to set whether to display the system menu.

SW8 is used to set the default user level.

SW10 is used to set the COM2 port type (RS485 or RS4)