ABB 5SHY 4045L0006 IGCT 4500V 91MM 3BHB030310R0001

Product basic information

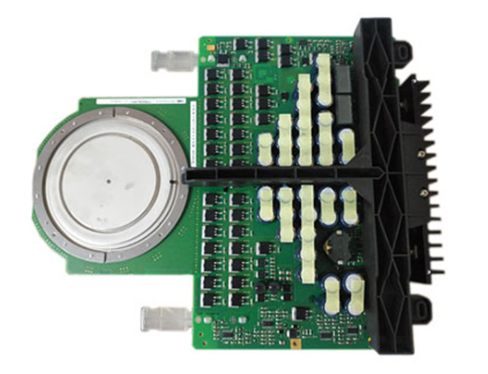

ABB 5SHY 4045L0006 IGCT (Integrated Gate Converter Thyristor) module, paired with 3BHB030310R0001, is a key power electronic device designed specifically for high voltage and high power applications. The module is produced in the United States, Czech Republic, Switzerland, Finland and other places, with a net weight of about 3kg and an overall size of 350 × 300 × 50mm. It integrates powerful power control functions in a compact space.

Brand background

ABB, as a globally renowned electrical and automation technology company, was established in 1988 through the merger of ASEA from Sweden and BBC from Switzerland, with its headquarters located in Zurich, Switzerland. With a profound technical foundation and a spirit of continuous innovation, we have launched numerous products in various fields such as power, industry, transportation, and construction, establishing a good reputation in the industry with high precision, reliability, and stability. We continue to provide high-quality products and services to global customers, helping various industries improve production efficiency and product quality, and promoting technological progress in the industry.

Key performance parameters

High voltage resistance characteristics: With a rated voltage of 4500V, it can withstand extremely high voltage stress and operate stably in high voltage environments. This characteristic makes it an ideal choice for high-voltage power transmission and distribution systems, high-voltage motor drives, and other fields, which can effectively cope with complex voltage changes in the power grid and ensure the reliable operation of the power system. For example, in high-voltage direct current transmission (HVDC) projects, the on/off of high-voltage current can be precisely controlled to achieve efficient long-distance power transmission.

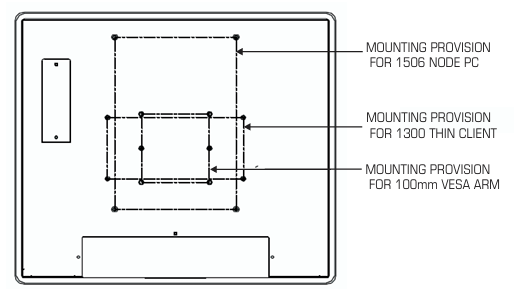

Moderate physical specifications: The 91mm specification design is not simply a size parameter, but the result of comprehensive consideration of heat dissipation performance, electrical connection convenience, and overall module stability. Through the carefully designed 91mm size and specific heat dissipation structure, it can ensure the rapid dissipation of heat generated inside the module during high-power operation, maintain the normal operating temperature of IGCT, and avoid performance degradation or device damage caused by overheating. At the same time, this size is also convenient for integrated installation with other power electronic components, achieving a compact and efficient layout of power control systems within limited control cabinet space.

Performance advantages

Excellent power control capability: The integrated gate commutation technology endows this module with outstanding power control performance, enabling fast and accurate switching actions under high voltage and high current conditions. Compared to traditional thyristors, its switching speed is greatly improved, and it can complete conduction and turn off operations in microseconds, greatly improving power conversion efficiency. In industrial frequency converter applications, it can quickly respond to motor speed adjustment requirements, achieve smooth and efficient control of motors, and reduce energy consumption and harmonic interference during motor operation.

High reliability and stability: Advanced manufacturing processes and high-quality materials are used, and strict quality inspection processes are carried out to ensure that the module can operate stably even in harsh industrial environments. From component screening to module assembly, every step follows strict standards, effectively reducing potential failure points and improving the overall reliability of the product. In harsh working conditions such as metallurgy and mining, even facing high dust, strong electromagnetic interference, and frequent voltage fluctuations, the IGCT module can still maintain a stable working state, providing continuous and reliable power control for production equipment.

Working principle

IGCT combines the advantages of low on state loss of thyristors and stable turn off capability of transistors. Internally, the GTO chip is integrated with anti parallel diodes and gate driver circuits, and connected to the gate driver in a low inductance manner. When a positive trigger signal is applied to the gate, the device conducts and current flows from the anode to the cathode; When applying a reverse turn off signal, the gate drive circuit is used to extract gate charges, causing the device to quickly turn off and complete the current control process.

Precautions

Installation environment: Avoid installing in high temperature, high humidity, and strong electromagnetic interference environments. Keep the installation location well ventilated, away from heat and water sources, and prevent module performance from being affected by environmental factors. High temperatures may cause high junction temperatures, affecting service life.

Electrical connection: Strictly follow the instructions for electrical connection, ensure that the wiring is firm and correct, and prevent problems such as virtual connection and short circuit, otherwise it may cause electrical accidents, damage modules and other equipment.

Operation and maintenance monitoring: Regularly inspect modules, monitor working temperature, current, voltage and other parameters, promptly handle any abnormalities, prevent faults through early maintenance, and ensure long-term stable operation of modules.