ABB AFS series switches

Product Overview

Core positioning: A fully managed modular Ethernet switch designed specifically for the power industry (substations, distribution networks, and in plant communication), focusing on core requirements such as high reliability, electromagnetic interference resistance, and wide temperature operation in power scenarios, supporting the expansion of smart grid applications (such as renewable energy integration and distribution automation).

Product series division:

|Model series | Installation method | Core configuration differences | Number of ports | Power consumption range | Special functions|

|AFS650/655 | DIN rail (optional wall mounted) | Compact design, supports multi-mode/single-mode optical ports | Up to 10 (including 3 GbE ports) | 12-21 W | Redundant power supply (18-60VDC/48-320VDC/90-265VAC)|

|AFS670/675 | 19 inch rack | Modular design, 12 slots (2 ports/module) | Up to 28 slots (electrical/optical/SFP cage) | 10-40 W (no PoE) | Supports PoE (power type H/Z), redundant power supply (18-60VDC/77-300VDC/90-265VAC)|

|AFS677/AFR677 | 19 inch rack | Fixed port design | 16 GbE combo ports (RJ45/SFP) | 10-40 W (no PoE) | AFR677 supports L3 routing (RIPv1/v2, OSPFv2, VRRP)|

Key compliance and technical parameters

Certification and anti-interference standards:

|Standard Category | Core Standard Content|

|Industry certification | IEC61850 approval, IEEE1613 approval|

|Electromagnetic compatibility (EMC/EMI) | EN61000-4-2: 8kV contact discharge, 15kV air discharge; EN61000-4-3:35Vpp/m(80-2700MHz); IEEE C37.90.3: ± 8kV contact discharge, ± 15kV air discharge|

|Mechanical testing | IEC60068-2-27: 15g impact (11ms, 18 times); IEC60068-2-6: Vibration Test (2-13.2Hz/1mm/90min, etc.)|

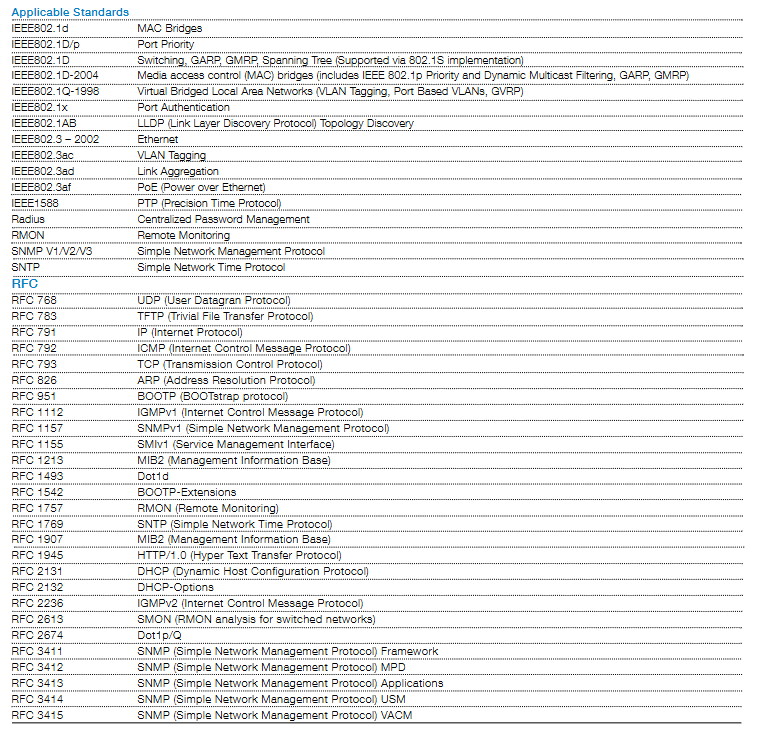

|Network standards | IEEE802.1d/p/Qx/AB, IEEE802.3 series, IEEE1588 (PTP), etc|

Core technical parameters:

Working temperature: Standard 0-60 ℃, optional -40 ℃ to 85 ℃ (continuous operation)

Switching characteristics: Store and forward mode, typical switching delay of 2.7 μ s (100Mbit/s), MAC address table capacity of 8000 entries

Network function: 4042 VLANs (supporting 255 at the same time), 4 priority queues, supporting port rate limitation (kbps step), link aggregation IGMP snooping

Protection mechanism: Supports RSTP (IEEE802.1D), MRP (IEC62439), E-MRP, and fast switching of ring topology

Power specifications: AFS650/655 supports 18-60VDC (low voltage), 48-320VDC/90-265VAC (high voltage); The AFS670 series supports 18-60VDC (low voltage), 77-300VDC/90-265VAC (high voltage), all of which support redundant power supplies

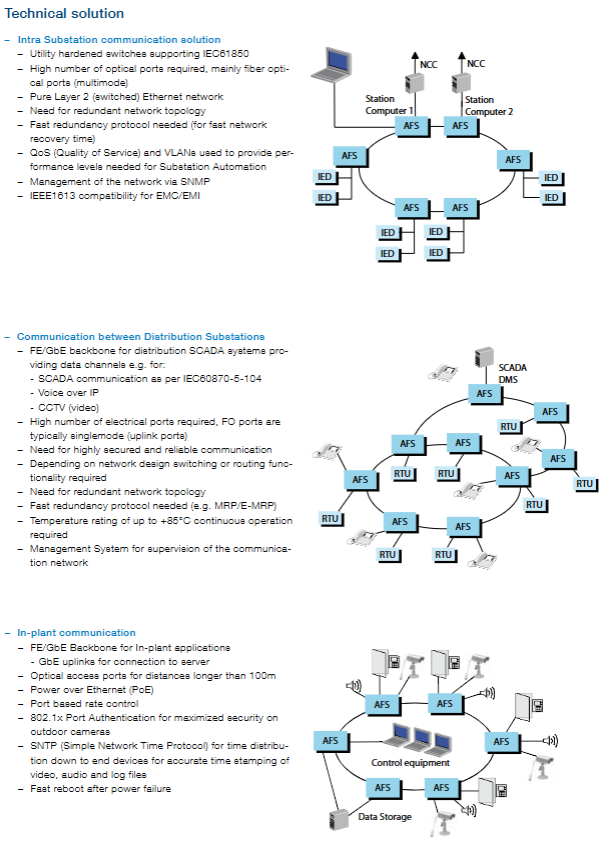

Three core application scenarios and solutions

Application scenario core requirement solution configuration

Substation automation low latency, high availability, IEC61850 compatibility, anti electromagnetic interference pure L2 switching network, redundant topology, multi-mode optical ports as the main, QoS/VLAN enabled, SNMP management supported, GOOSE message and sampling value transmission supported

Long distance transmission of power distribution communication, reliable transmission of SCADA data, multi service carrying FE/GbE backbone network, single-mode optical port (uplink), supporting IEC60870-5-104 protocol, redundant topology+MRP/E-MRP, compatible with VoIP and renewable energy data transmission

In plant communication with high bandwidth (CCTV), equipment power supply, time synchronization, high security GbE upstream connection server, PoE power supply (camera), 802.1x port authentication, SNTP time synchronization, port rate control, supporting CCTV, access control, and public address system communication

Security and management features

Security features: IEEE802.1x port authentication, SSH encryption, Radius centralized password management, multi-level user passwords, port disabling, SNMPv3 encryption authentication, VLAN isolation (IEEE802.1Q)

Management methods: SNMP V1/V2/V3, command-line interface (Telnet), web interface, port mirroring, RMON remote monitoring, LLDP topology auto discovery, SFP diagnosis, configuration recovery adapter (CRA), watchdog and rollback function

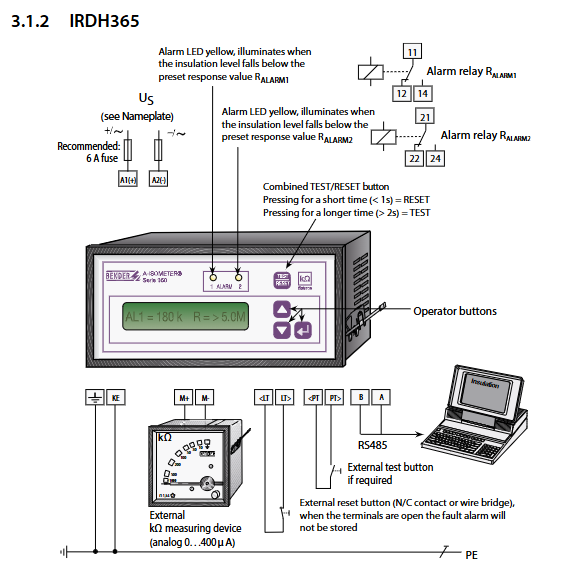

Alarm mechanism: Diagnostic LED indicator light, 2 sets of alarm contacts, local logs and Syslog reports

Customer Core Value

Power level adaptation: high EMC/EMI anti-interference ability, wide temperature working range, redundant power supply, suitable for harsh environments in substations

High availability: fanless design, high MTBF, fast switching of link failures, ensuring uninterrupted critical business operations

Flexible Expansion: Port density can be expanded (8-28), supporting FE/GbE, PoE, L3 routing (AFR677), and adapting to different scale requirements

Integrated solution: integrated into ABB’s power communication ecosystem, supporting multi business integration such as SCADA, IEC61850, voice, etc

Key issues

Question 1: What are the specific power level characteristics of ABB AFS series switches reflected in? Why can it adapt to the harsh environment of substations?

Answer: The power level characteristics are mainly reflected in three aspects: ① Environmental adaptation: supporting standard working temperature of 0-60 ℃, optional wide temperature range of -40 ℃ to 85 ℃, fanless design+optional normal coating, and can withstand extreme temperatures; ② Anti interference capability: certified by IEEE1613, compliant with EN61000-4 series (ESD 8kV contact/15kV air discharge, surge 2kV line to ground) and IEEE C37.90 series standards, resistant to strong electromagnetic interference; ③ Reliability design: Supports redundant power supply (AC/DC wide voltage input, such as AFS650 supporting 48-320VDC), fast protection mechanism (MRP/E-MRP, ring topology fast switching), high MTBF guarantee, avoiding single point failure. These characteristics enable it to directly adapt to harsh environments such as severe electromagnetic pollution, large temperature fluctuations, and high requirements for continuity in substations.

Question 2: What are the core differences between different models of ABB AFS series? How to choose the appropriate model based on the application scenario?

Answer: The core differences are concentrated in three dimensions: installation method, port configuration, and functional expansion. The selection logic is as follows:

Model Series Core Differences Adaptation Scenarios

AFS650/655 DIN rail installation, up to 10 ports, no L3 routing for small substations, distribution terminals, and distributed equipment communication within the factory (limited space, low port requirements)

AFS670/675 19 inch rack, modular design (up to 28 ports), supporting PoE for large-scale substation automation, requiring high port density distribution communication backbone network (multi device access, requiring PoE power supply for cameras/terminals)

AFS677/AFR677 19 inch rack, 16 GbE combo ports, AFR677 supports L3 routing (RIPv1/v2, OSPFv2) for cross regional power distribution communication and complex networks requiring routing functionality (multi subnet interconnection, backbone network hierarchical architecture)

Question 3: What are the key technical measures for ABB AFS series switches to ensure the reliability of critical business in the power industry, such as IEC61850 data transmission?

Answer: Key technical measures include: ① Fast protection mechanism: supporting MRP (Media Redundancy Protocol), E-MRP, and RSTP, which can achieve fast switching in case of link failure in ring topology, reducing the interruption time of IEC61850 GOOSE message and sampling value transmission; ② Network isolation and priority: Supports 4042 VLANs (255 at the same time) and 4 priority queues, isolates different services through IEEE802.1Q VLANs, ensures QoS guarantees priority transmission of IEC61850 critical data, and avoids bandwidth preemption; ③ Hardware redundancy: supports redundant power input to avoid equipment shutdown caused by power failure; ④ Management and monitoring: Real time monitoring of network status through SNMP V3, RMON, LLDP topology discovery, combined with alarm contacts and Syslog reports, to quickly locate faults; ⑤ Protocol compatibility: Native support for IEC61850 protocol ensures seamless integration with intelligent electronic devices (IEDs), reducing latency and fault risks caused by protocol conversion