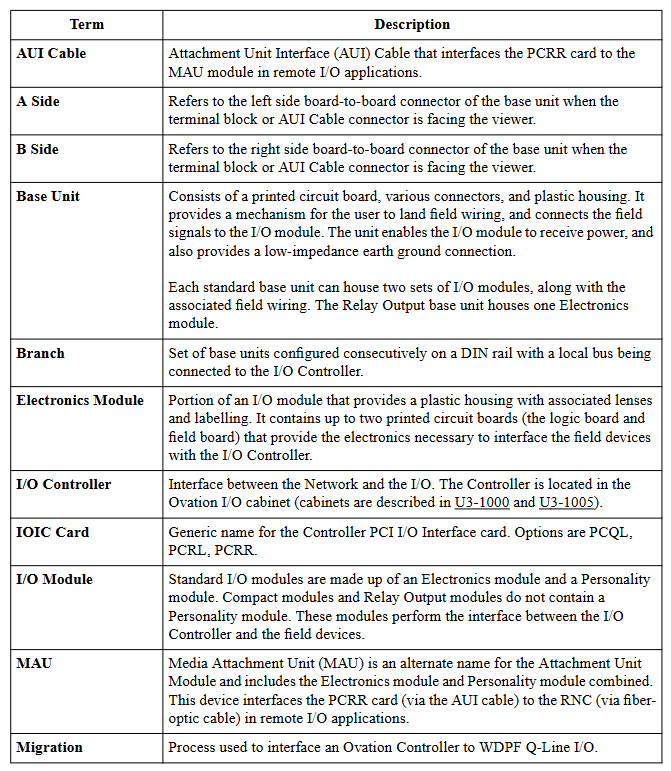

Emerson Martens Standard Signal Instrument S 1010

Equipment Overview

Martens Standard Signal Instrument S 1010 is designed to measure industrial standard signals of 0/4… 20mA or 0… 10VDC. It has a built-in transmitter power supply and can be directly connected to 2-wire and 3-wire transmitters (such as those used for pressure or temperature measurement). Its indication range and decimal point can be freely programmed within the range of ± 9999 (0) digits, suitable for signal measurement and monitoring in industrial sites.

Main characteristics

Display function: Equipped with a 14.2mm red LED display screen, the indication range is ± 9999 (0) digits, and the indication range and decimal point can be freely programmed.

Alarm output: Up to 2 alarm outputs, the switch performance of the alarm output can be programmed to the minimum or maximum function.

Analog output: It can generate analog output signals proportional to the input signal, including 0… 20mA/0… 10V DC, 4… 20mA/2… 10V DC. The output will automatically switch from current signal to voltage signal according to the load.

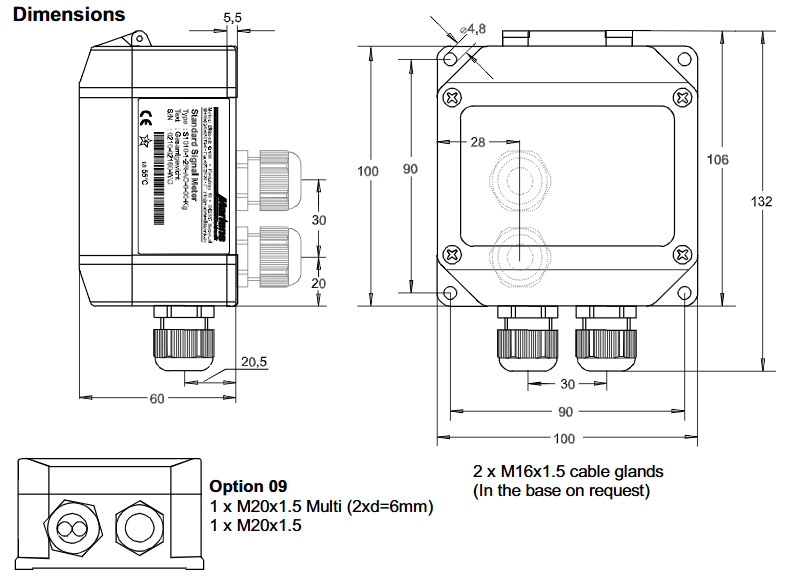

Shell and Protection: The on-site shell with snap on cover is used, equipped with 2 M16x1.5 cable glands (other specifications can refer to option 09 or customized as needed), and the protection level is IP65.

Other functions: Parameters can be programmed through the front film keyboard; Equipped with digital filtering function, it will continuously average the last 16 measurement values and display the results on the screen after activation.

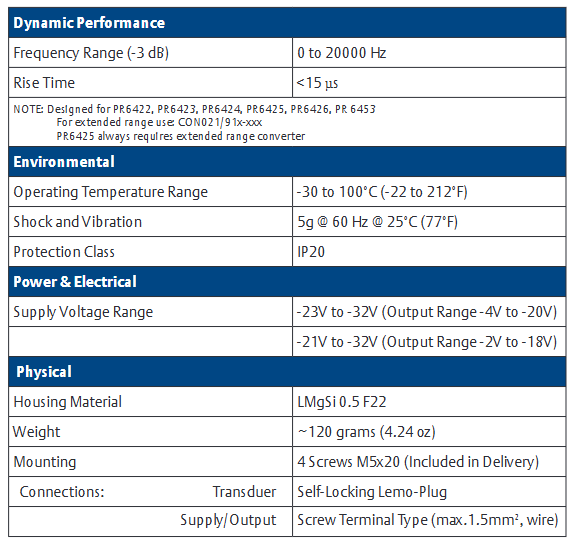

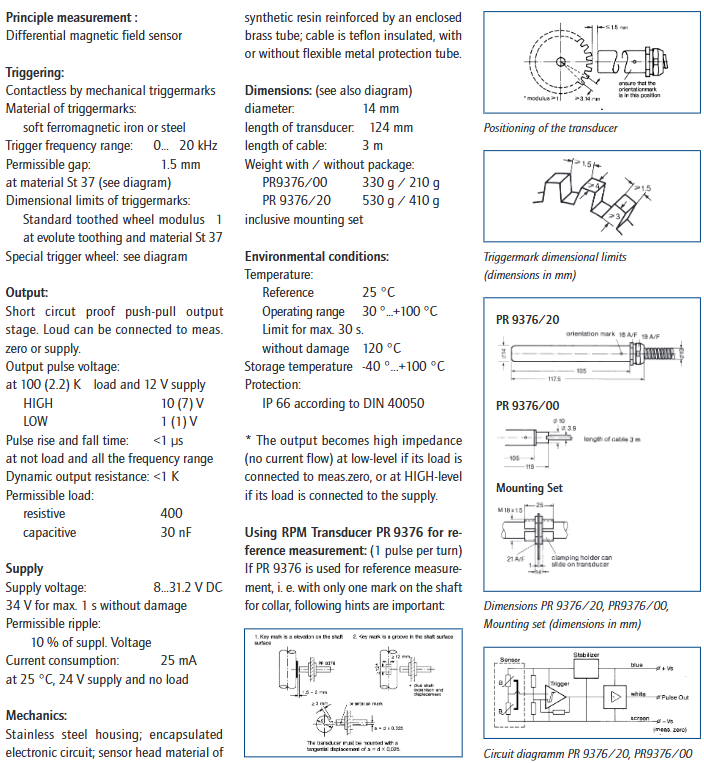

Technical parameters

power supply

Power supply voltage: 230V AC ± 10%, 115V AC ± 10%, 24V AC ± 10%, or 24V DC ± 15%.

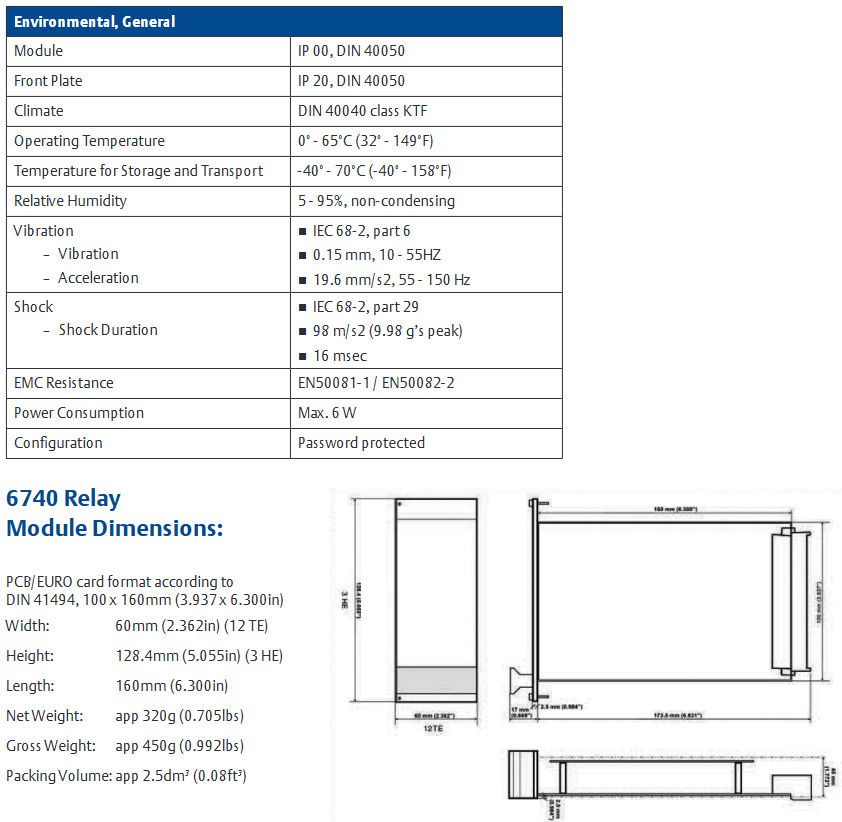

Power consumption: maximum 3.5VA, 5VA with analog output.

Working temperature: -20…+55 ° C (standard), with an extended temperature range available upon request.

Rated voltage: 250V (according to VDE 0110, between input/output/supply voltage), overvoltage category III.

Test voltage: 4kV between input/output/supply voltage.

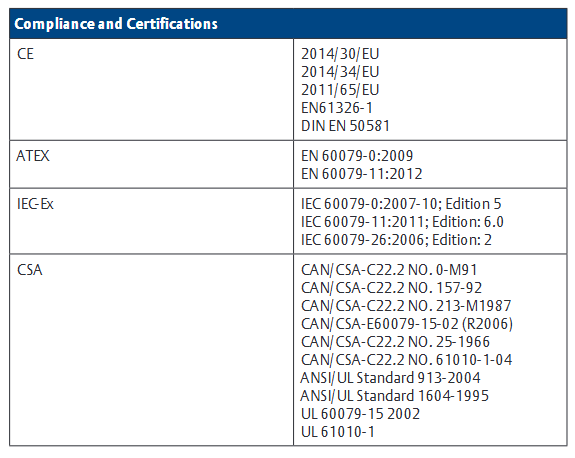

Electromagnetic compatibility: Complies with EN55022, EN60555, IEC1000-3/4/5/11/13 standards.

input

Current input: 0/4… 20mA, Ri=10 Ω.

Voltage input: 0… 10V, Ri>100k Ω.

Accuracy:<0.1% ± 2 digits.

Temperature coefficient: 0.004%/K.

Transmitter power supply: U ₀ about 24V, Ri about 150 Ω, maximum 50mA (25mA with relay and analog output).

display

Display screen: red LED, 14.2mm.

Display range: ± 9999 (0), with leading zero suppression.

Parameter display: 2 red LEDs, 7mm (parameter and output indicator).

output

Relay: SPDT, 250V AC<250VA<2A, 300V DC<50W<2A.

Analog output: 0/4… 20mA (load ≤ 500 Ω), 0/2… 10V (load>500 Ω), not isolated from input, automatically switches output types according to load.

Accuracy: 0.1%; Temperature coefficient 0.01%/K.

other

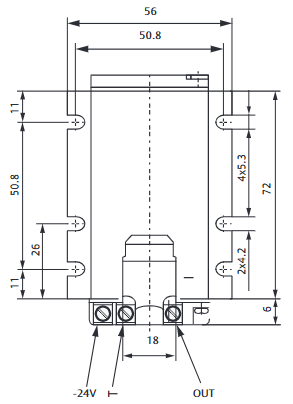

Shell: Made of polyamide material, containing glass fiber PA6-GF15/15, keyboard made of polyester material.

Weight: Maximum 450g.

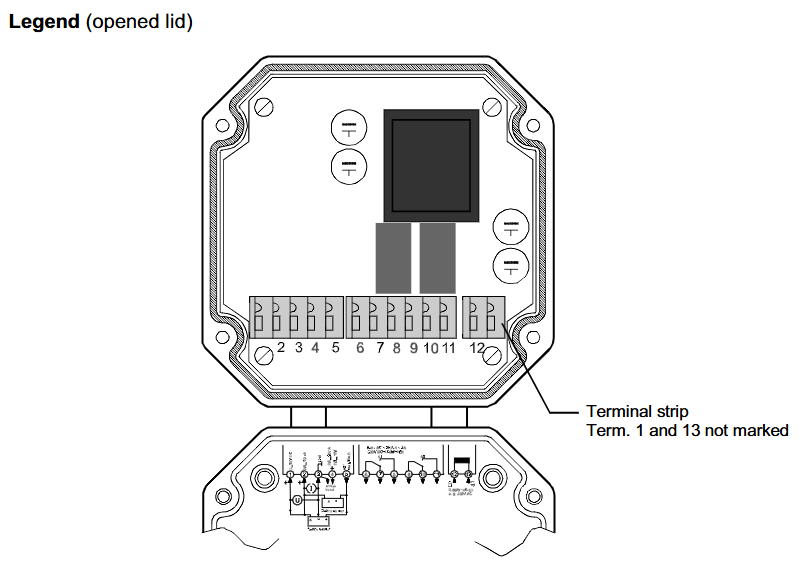

Electrical connection: Clamp terminal, 2mm ² single stranded wire, 1mm ² flexible wire, AWG14。

Protection: IP65 (enclosure), IP20 (terminals), compliant with German BGV A2 anti touch standard.

Operation and Configuration

Operation level: The device operation is divided into 2 levels. After the power is turned on, the device initializes and displays “Int”. After initialization, it enters the working level and can pre select the alarm output set point (if any). Press and hold the parameter button for more than 2 seconds to enter the configuration level of the program, where all parameters defining device functions can be programmed. If the configuration is completed or no button is pressed for more than 2 minutes, the program will return to the working level. Long press the parameter button for 2 seconds to exit the configuration level at any time.

error code

If the input signal exceeds the programmed measurement range by more than 3%, the A/D converter will be overloaded and the display screen will flash at a frequency of about 1Hz.

Error 1 “indicates an EEPROM test error. Pressing the parameter button will reload the EEPROM copy, and the device will operate according to factory settings. If the copy is invalid, the device needs to be sent to the factory for repair.

Loc “indicates program lock, refer to configuration page 7.

Parameter settings: The work level can display actual values, alarm output indicators, adjust display brightness, display maximum/minimum readings, set alarm output setpoints, etc; The configuration level can set parameters such as digital filtering, indication correction, input signal, fixed zero point, decimal point position, starting and ending values of indication range, alarm output set point, hysteresis, analog output, factory setting code, program lock, etc.

Order Code

The ordering code consists of multiple parts, representing input, alarm output, analog output, supply voltage, options, units, and additional text:

Input: 1 represents input standard signal 0/4… 20mA, 0… 10V DC, built-in transmitter power supply 24V DC maximum 50mA.

Alarm output: 00 indicates not installed, 2R indicates 2 alarm outputs (relays).

Analog output: 00 indicates not installed, AO indicates analog output 0/4. 20mA, 0/2… 10V DC (not isolated).

Supply voltage: 0 represents 230V 50/60Hz ± 10%, 1 represents 115V 50/60Hz ± 10%, 4 represents 24V 50/60Hz ± 10%, and 5 represents 24VDC ± 15%.

Options: 00 indicates no options, 01 indicates minimum and maximum value retention function, 07 indicates programmable display brightness, 08 indicates freely programmable analog output, 09 indicates 1 M20x1.5 multi-purpose (2x6mm), 1 M20x1.5.

Unit: appears in the unit field.

Additional Text: will be placed in the additional text field, with a maximum size of 3mm x 70mm (height x width).