Emerson DeltaV Bulk Power Supplies

Basic Overview

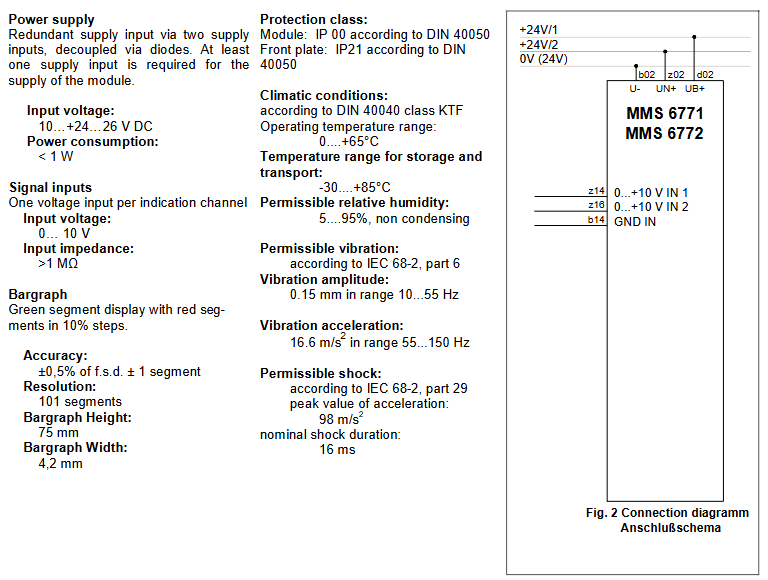

DeltaV Bulk Power Supplies is an efficient and reliable power solution developed by Emerson for the DeltaV distributed control system. It covers 5A, 10A, 20A, 40A series AC-DC power supplies and 20A, 40A, 80A series redundant modules. It also offers special models with conformal coating (anti-corrosion coating) and IP67 protection level, which can meet the power supply needs of system electronic equipment and field equipment. It is the core power supply component of the DeltaV system, with advantages such as ease of use, high availability, flexibility, and small size.

Core advantages

(1) Strong usability and easy installation

Standardized installation: All conventional models support horizontal installation on T-shaped DIN rails, with label text facing up to complete basic fixation without the need for complex tools; The IP67 protection level model (VE5139/VE5140) adopts chassis installation (through integrated installation of ear tabs), suitable for outdoor or humid environments.

Unified power supply output: Mainstream models provide 24V DC standard output (some models support 12V DC), with a voltage regulation range of 23.5-28.5V DC (11.5-15.5V DC for 12V models), which can directly match the power supply needs of DeltaV systems and field devices without additional voltage conversion.

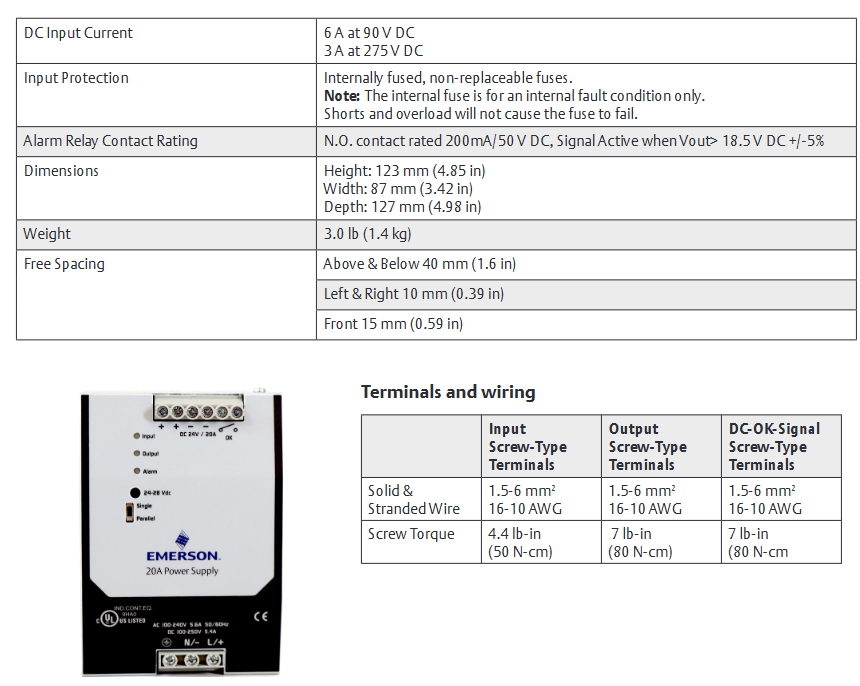

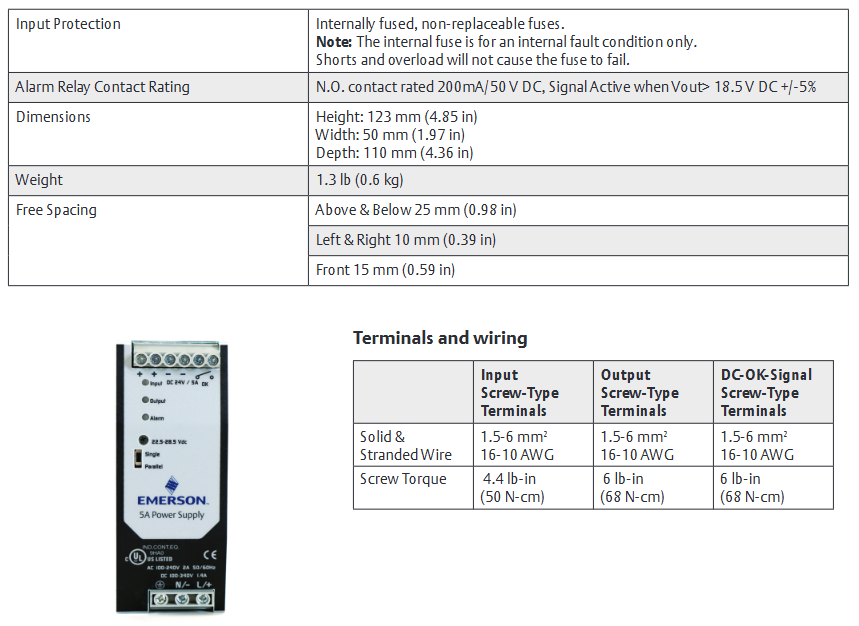

Clear status feedback: Equipped with a built-in DC-OK alarm relay (normally open contact, 200mA/50V DC), it triggers a signal when the output voltage is greater than 18.5V DC (± 5%), facilitating real-time monitoring of power operation status and timely detection of faults.

(2) High availability, stable and reliable

Efficient redundancy design: The redundant module is based on active MOSFET technology, which has a lower voltage drop (typical value of 0.2V) and higher efficiency compared to traditional diode modules, reducing heat loss and improving system reliability; Support 1:1 redundant configuration, automatic switching between primary and backup power sources to avoid power outages caused by single point failures.

Wide environmental adaptability: Conventional models operate at temperatures ranging from -40 ° C to 70 ° C (with power linearly reduced to 75% at 60 ° C to 70 ° C), storage temperatures ranging from -40 ° C to 85%, relative humidity ranging from 5% to 95% (without condensation), shock resistance (10g RMS, three-axis, 11ms per axis), and vibration resistance (2.5g RMS, 10-2000Hz random vibration); The IP67 model (VE5139/VE5140) has upgraded its protection level to IP66/67, supporting operation at -40 ° C~70 ° C (with power down to 50% at 60 ° C~70 ° C), and can withstand 100% condensation humidity, making it suitable for outdoor, humid, or dusty environments.

Multiple protection mechanisms: All models have built-in non replaceable fuses (only for internal faults, short circuits/overloads will not cause fuse failure), with overcurrent and overvoltage protection; Some models (such as IP67 series) comply with NEC Class 2 standard (UL1310), and the electronic current limiting design further ensures safety.

(3) High flexibility and controllable cost

Multi specification selection: current coverage of 3.8A~40A (single channel), 7.6A (dual channel), VE5140), The power coverage ranges from 100W to 960W, and can be flexibly selected according to the system load; Redundant module current matching power specifications (20A/40A/80A), supporting load sharing to meet the redundancy requirements of systems of different scales.

Special requirement adaptation: Provide models with conformal coatings (such as VE5122/VE5124, etc.) that comply with ISA-S71.04-1985 G3 level air pollutant standards and are suitable for corrosive environments; The IP67 model (VE5139/VE5140) features a waterproof and dustproof design, suitable for outdoor or harsh on-site environments, without the need for additional protective enclosures.

Low power consumption and energy saving: Conventional models have AC efficiency>88% (5A model)~93% (40A model), active power factor correction (typical value 0.92~0.98), reducing grid losses; The idle power consumption of redundant modules is as low as 0.5mW, further reducing system energy consumption.

(4) Small volume design, saving space

The standard model has a uniform height of 123mm (4.85in), a width of only 50mm (5A)~180mm (40A), and a depth of 110mm~127mm. It requires small installation gaps (25mm~40mm up and down, 10mm~15mm left and right, 15mm in front) and can be densely installed in cabinets, greatly saving space; The IP67 model has a compact size (such as VE5139:120.1mm × 177.8mm × 45.7mm) and does not require additional space for outdoor installation.

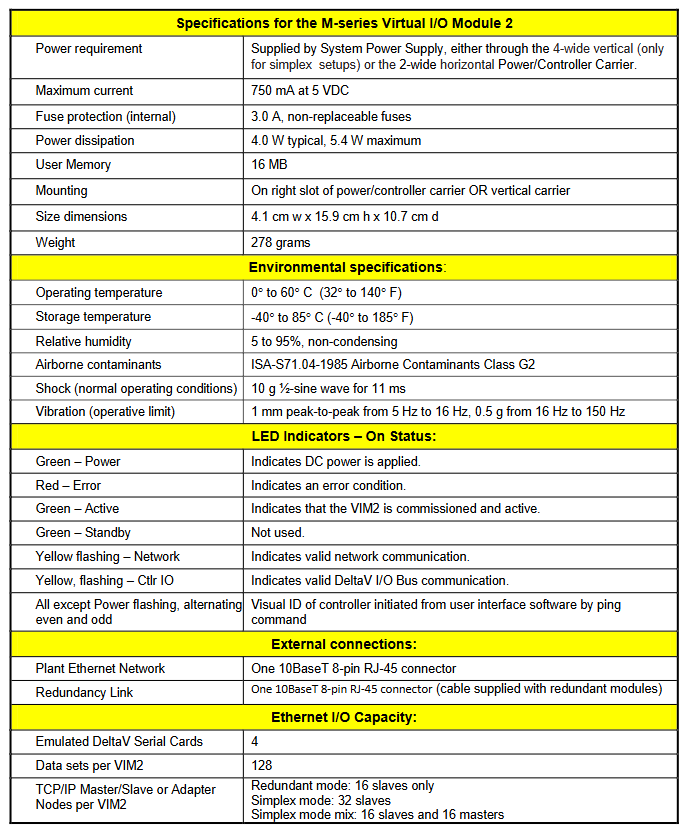

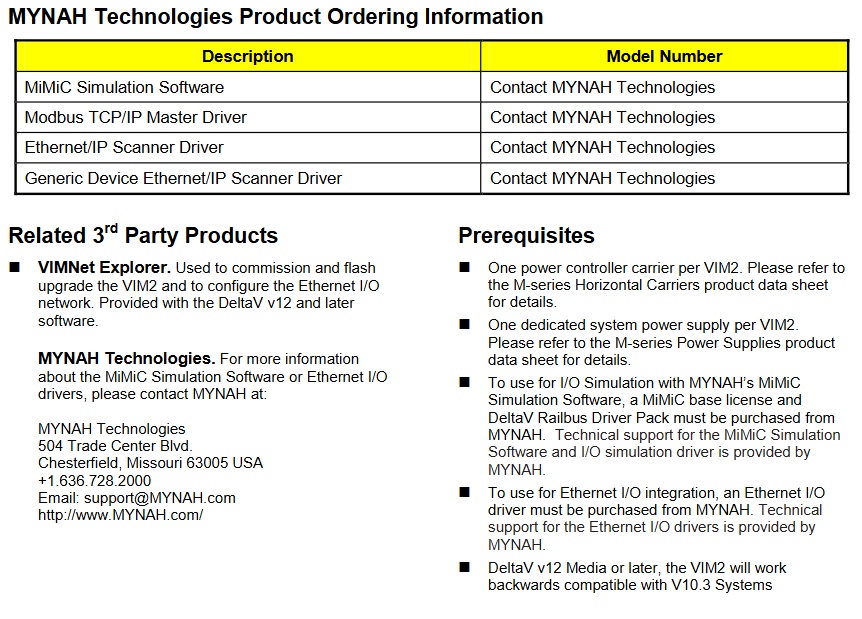

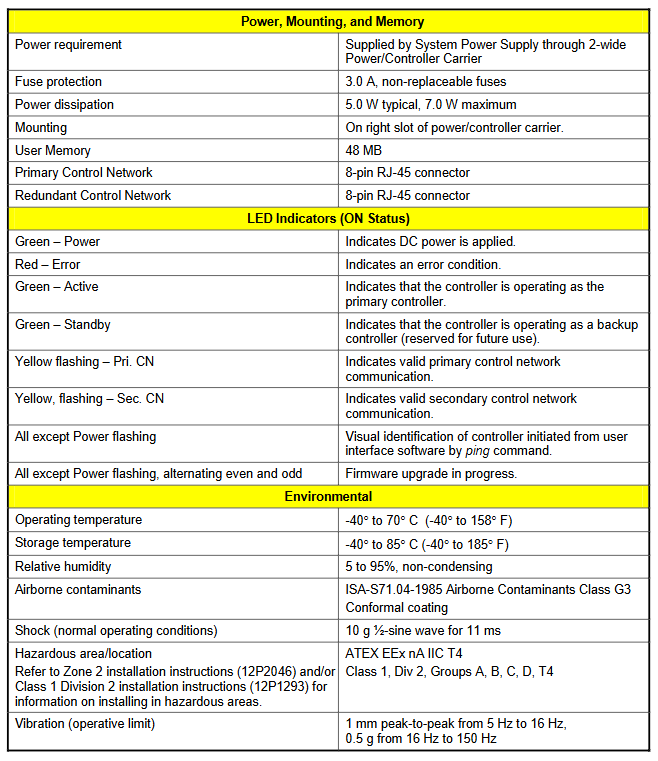

Main product models and core parameters

(1) AC-DC power module (regular model)

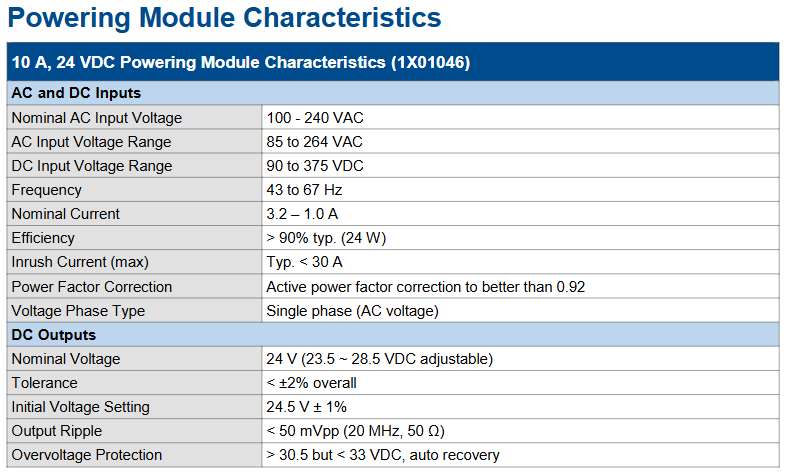

Model Input Specification (AC/DC) Output Specification (DC) Core Characteristics

VE5138 85-264V AC/90-375V DC, 43-67Hz 24V/5A, 120W (peak 180W/4s) efficiency>88%, ripple<50mVpp, protection IP20

VE5123 85-264V AC/90-375V DC, 43-67Hz 24V/10A, 240W (peak 360W/4s) efficiency>90%, ripple<50mVpp, protection IP20

VE5126 85-264V AC/90-275V DC, 43-67Hz 24V/20A, 480W (peak 720W/4s) efficiency>92%, ripple<100mVpp, protection IP20

VE5128 85-264V AC/108-375V DC, 43-67Hz 24V/40A, 960W (peak 1440W/4s) efficiency>93%, ripple<200mVpp, protection IP20

VE5137 85-264V AC/90-375V DC, 43-67Hz 12V/15A, 180W (peak 270W/4s) efficiency>86.5%, ripple<100mVpp, protection IP20

VE5122~VE5129 are the same as the corresponding models mentioned above, with the addition of a conforming coating, suitable for G3 corrosive environments

(2) AC-DC power module (IP67 protection model)

Model Input Specification (AC/DC) Output Specification (DC) Core Characteristics

VE5139 85-264V AC/100-353V DC, 50/60Hz 24V/3.8A, 100W IP66/67 protection, efficiency>80%, ripple<50mVpp, supports outdoor installation

VE5140 85-264V AC/100-353V DC, 50/60Hz 24V/7.6A (dual 3.8A), 2 × 100W IP66/67 protection, efficiency>85%, ripple<50mVpp, dual independent output

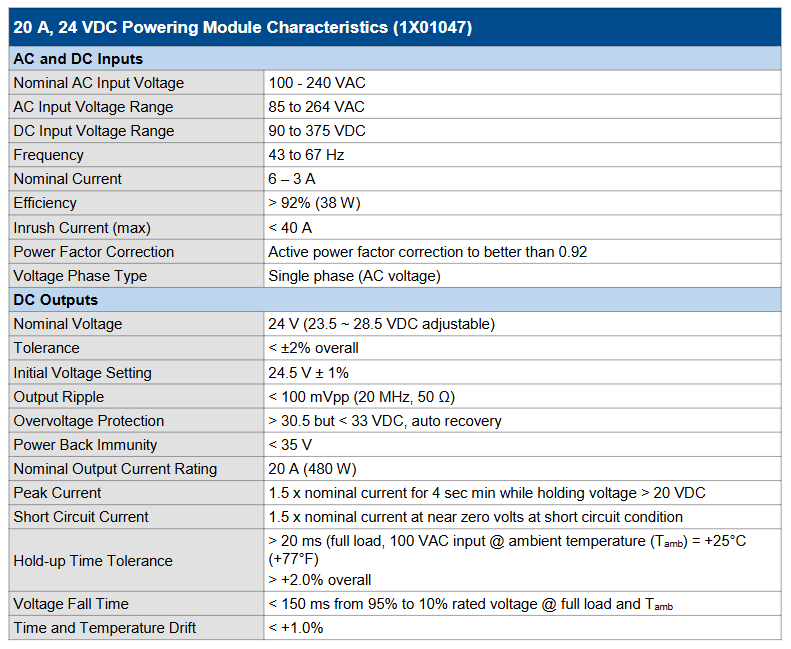

(3) Redundant module

Model Input Voltage Range (DC) Output Current Specification Core Characteristics

VE5134 10.8-30.8V DC 0-26A (continuous), 26-50A (5s) voltage drop 0.2V, no-load power consumption 0.5mW, supports 20A power redundancy

VE5135 10.8-30.8V DC 0-40A (continuous), 40-65A (5s) voltage drop 0.2V, no-load power consumption 0.5mW, supports 40A power redundancy

VE5136 10.8-30.8V DC 0-80A (continuous), 80-120A (5s) voltage drop 0.2V, no-load power consumption 1.18mW, supports 80A power redundancy

VE5131~VE5133 are the same as the corresponding models mentioned above, with the addition of a conforming coating, suitable for G3 corrosive environments

Certification and Compliance

All regular models have passed the following certifications to ensure industry compliance:

Safety certification: UL 508, CSA C22.2 No.107.1 (industrial control equipment), UL 60950-1/CSA C22.2 No.60950-1 (ITE equipment), compliant with the Low Voltage Directive (IEC/EN60950-1).

Hazardous Area Certification: UL 60079-15/CSA E60079-15(Class I, Zone 2),ATEX II 3 G Ex ec nC IIC Gc,IECEx Ex ec nC IIC Gc,GOST Zone 2( Russia).

Ship certification: ABS, DNV-GL, Lloyd’s Register (LR), BV Type Approval, compliant with IACS E10 standard.

EMC compliance: Complies with EN 61326-1 (EMC) and EN 61010-1 (safety) to ensure resistance to electromagnetic interference in industrial environments.

Note: VE5139/VE5140 have no hazardous area and ship certification, and are only applicable to regular environments.

Ordering and matching

Model differentiation: Regular models and models with regular coatings are distinguished by suffixes (such as VE5138 for 5A regular and VE5122 for coating); The IP67 model is an independent series (VE5139/VE5140).

Installation accessories: Conventional models require T-shaped DIN rails, IP67 models require M4 screws (tightening torque 1N · m); All models of wiring must comply with terminal specifications (such as input/output terminals supporting 1.5-6mm ² wires, screw torque 4.4-15.6lb in)