Foxboro Evo ™ Standard 200 Series Baseplates

Core positioning and subsystem roles

The standard 200 series substrate is Foxboro Evo ™ The core functions of the “hardware connection center” of the system include:

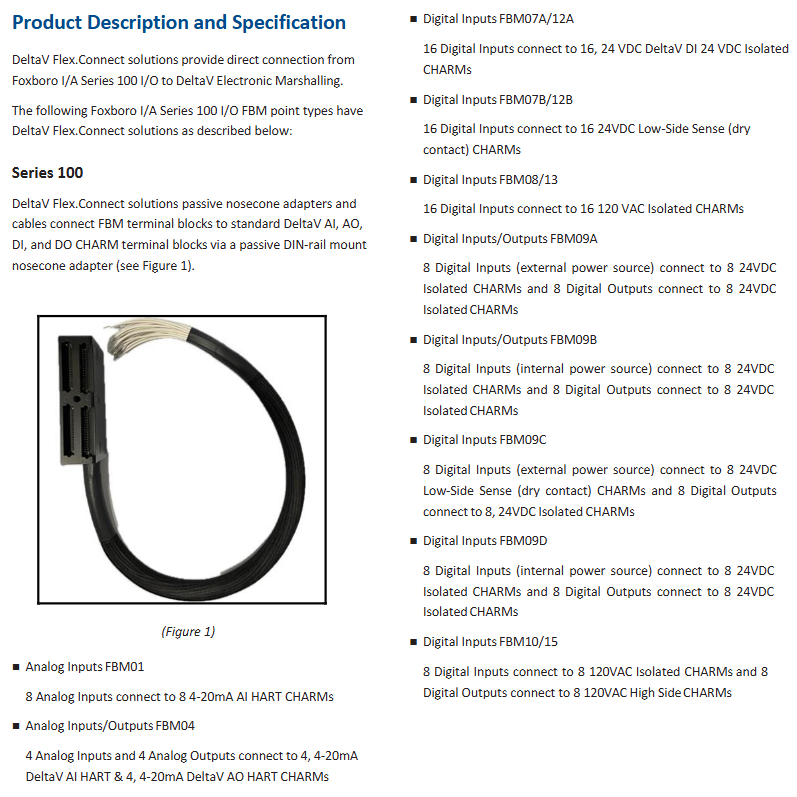

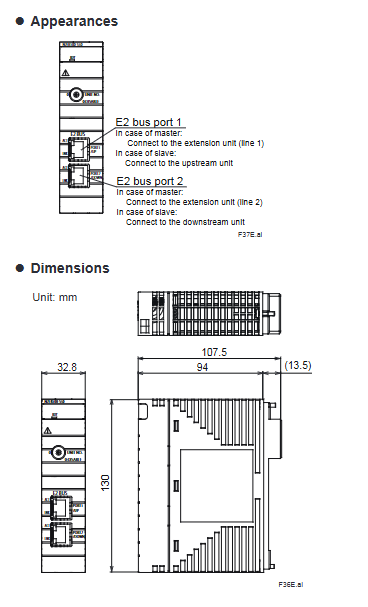

Module carrying and positioning: providing standardized slots for adaptation Field Control Processor(FCP)、Field Device Controller(FDC)、Field Communications Module(FCM)、Fieldbus Module(FBM) Waiting for multiple types of modules to achieve modular layout;

Signal and power distribution: Built in 2 Mbps HDLC redundant serial bus (Module Fieldbus), responsible for data exchange between modules; Simultaneously provide 24V DC redundant power interface to provide stable power supply for all mounted modules;

Redundancy and Scalability Support: Compatible with module level redundancy (such as FCP/FDC redundancy pairs), and supports online addition of substrates (requiring redundant buses) to meet system expansion requirements;

Compatibility Connection: Downward compatible with 100 Series FBM (requiring 268 Kbps fieldbus), upward compatible with Foxboro Evo control network, achieving smooth transition between old and new systems.

Classification and core functions of substrates

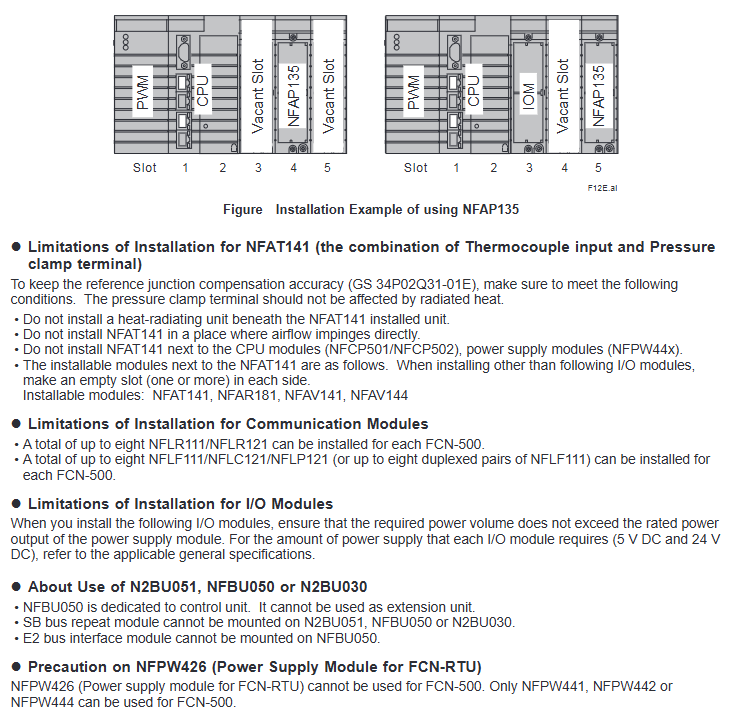

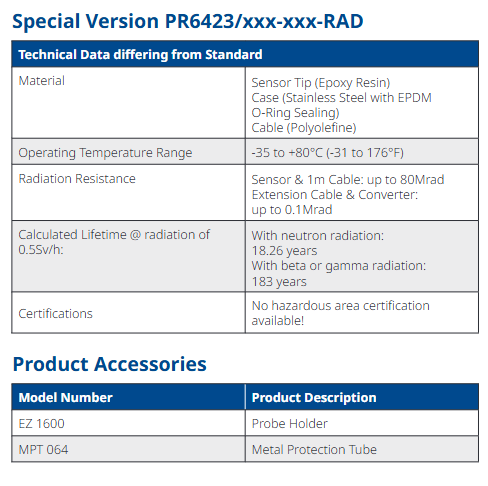

According to the number of slots (2/4/8), installation direction (horizontal/vertical), and supported module types, Standard 200 series substrates can be divided into multiple categories. The core functions and adaptation scenarios of each category are shown in the table below:

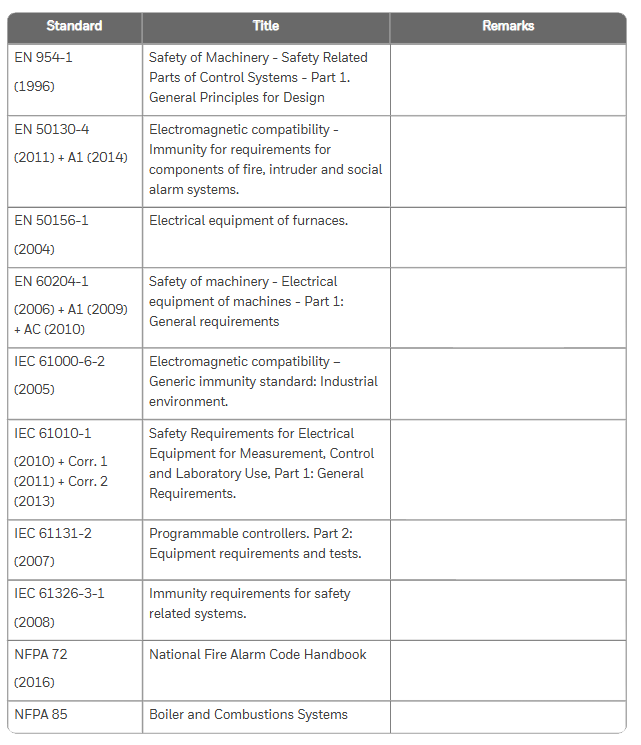

Substrate type, slot number, installation direction, support module/core function, typical model/substitution relationship, adaptation scenario

FCP280 dedicated substrate 2 horizontal/vertical – single module or redundant for FCP280;

-Supports 4 HDLC fieldbus ports (port 1 can be terminated through DIP switch, ports 2-4 have built-in termination);

-Optional dual cable version (independent A/B bus interface+time synchronization input) RH924YL (standard), RH100JX (dual cable);

Replacing the old CP60 related substrate requires high reliability control for medium to large-scale systems (such as chemical and electrical)

FDC280 dedicated substrate 2 vertical (horizontal orientation needs to be maintained) – single module or redundant pair FDC280;

-Support Ethernet/serial interface (for connecting field devices);

-Horizontal DIN rail installation is required to meet the classification certification RH101KF (unique model) for scenarios where FBM is not needed to directly connect on-site equipment (such as small control units)

FCP270 dedicated substrate 2 horizontal/vertical – single module or redundant for FCP270;

-Reserve installation space for fiber optic splitters/combiners;

-Hardwired address (substrate 0, no ID dialing) P0926HC (horizontal), P0926HW (vertical);

Non RoHS component small and medium-sized system upgrade (replacing old controllers)

FEM100 dedicated substrate 2 vertical – redundant pair for FEM100;

-Expand the number of FBMs supported by FCP270 (up to 4 expansion fieldbuses, each supporting 32 200 Series FBMs) P0973CG (non RoHS), RH924RT (replaces old model) FCP270 system I/O expansion

FBI specific substrate 2 vertical – FBI200/FBI100 redundant pair;

-FBI200 substrate with baud rate selection DIP switch;

-No need for hard wired address (no ID dialing) P0923LR (FBI100, non RoHS), RH924RT (FBI200) fieldbus isolation/filtering (anti-interference requirement scenario)

FCM/FBM universal substrate 2/4/8 horizontal/vertical -2 bits: single module/redundant pair FCM, or 2 FBMs (hard wired address 0, no ID dip code);

-4/8 bits: 4/8 FBMs or 2 FCMs+2 FBMs (including ID dialing, supporting substrate grouping) 2 bits: RH926KE (horizontal), RH926KH (vertical);

4-digit: RH926HM (replacing P0926HM);

8-bit: RH926HT (replacing P0926HT) pure I/O expansion or FCM+FBM combination scenario

FCP270+FEM100 hybrid substrate 4 vertical -2 redundant FCP270+2 redundant FEM100;

-No ID dialing, relying on FCP270 expansion port management P0973CN (non RoHS) FCP270 system for large-scale I/O expansion (such as multi device clusters)

FCP270+FBM hybrid substrate 4 horizontal/vertical -2 redundant FCP270+2 FBM (including ID dialing);

-Or 1 FCP270+3 FBM (non redundant) P0926HJ (1 FCP270+3 FBM), P0926HF (2 FCP270+2 FBM);

Non RoHS component small system (control+I/O integration, no redundancy requirements)

Key technical characteristics

(1) Module identification and address configuration

The substrate implements the mapping between modules and system software through the * * “Letterbug” string * * (6 bits), and the Letterbug generation rules for different modules are different:

FBM (with FCM): composed of “FCM’s first 4 Letterbug+substrate ID (dial setting)+module physical position (1-8)”;

FBM (with FCP280/FCP270): composed of “custom first 4 digits (not duplicated with FCP)+substrate ID (non FCP280 substrate dialing)+module position+FCP expansion port number (hexadecimal for FEM100 scenario)”;

FCP280/FDC280: Set “Soft Letterbug” through the module panel buttons;

FCP270/FCM100E: Set “Soft Letterbug” through the I/A Series Letterbug configuration tool.

(2) Redundancy and scalability

Module redundancy rules:

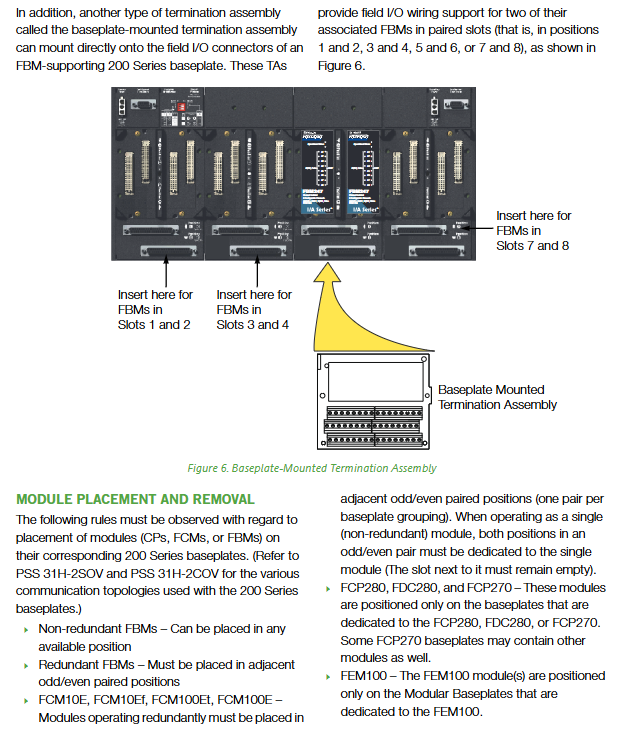

Redundant FBM/FCM should be installed in adjacent odd/even slot pairs (such as positions 1-2 and 3-4);

Non redundant FCM needs to occupy a pair of slots (adjacent slots are vacant);

FCP/FDC/FEM/FBI redundancy requires the use of a dedicated 2-digit substrate.

Online Expansion:

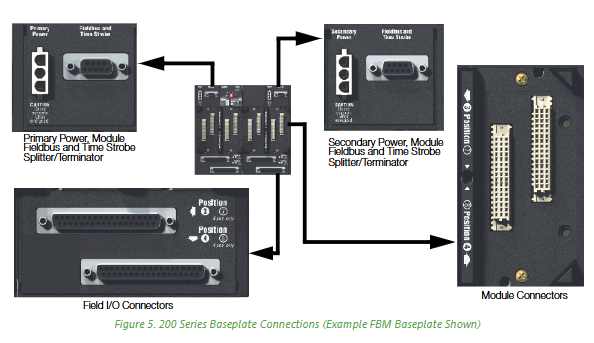

The system needs to have A/B redundant buses and split the bus signals through a “fieldbus splitter/terminator” (such as RH926KW);

When adding a new substrate, there is no need to interrupt the system operation, only the redundant cables need to be connected to the power supply.

(3) Signal and Communication Specifications

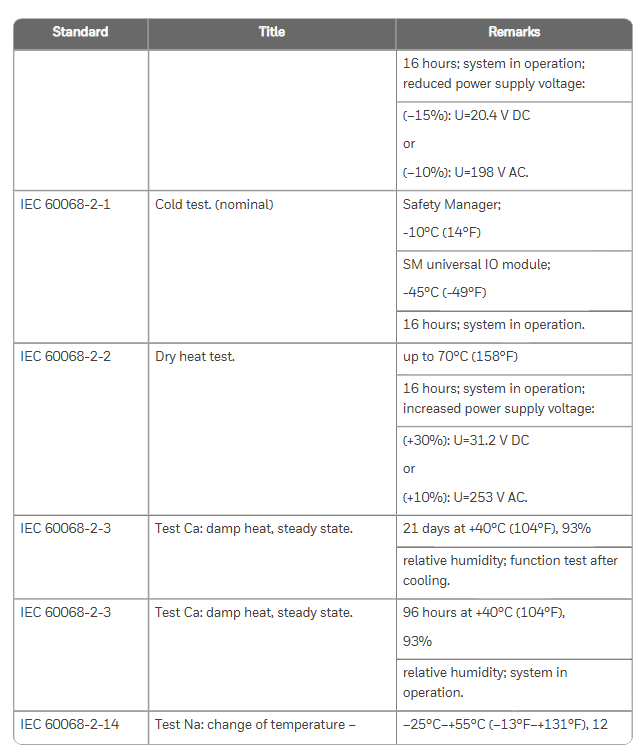

Specification category parameter details

Fieldbus type -200 Series module: 2 Mbps HDLC redundant serial bus (shielded twisted pair);

-100 Series module: 268 Kbps bus (dual axis cable)

Maximum communication distance -200 Series FBM (FBI200): 305 m (2 Mbps);

– 100 Series FBM(FBI200):1830 m(268 Kbps);

-FCP280 directly connected to 100 Series FBM: 915 meters

Time synchronization supports optional GPS time synchronization input (requires splitter/terminator, such as RH924ZQ(FCP280)、RH926KZ(FCM100E/FCP270))

The bus cable between signal isolation substrates is shielded twisted pair to reduce electromagnetic interference (EMI)

Detailed explanation of technical specifications

(1) Electrical and Environmental Specifications

Specification category parameter details

Power requirements – Input voltage: 24 V DC (redundant);

-Cable length: 0.4 m (16 inches) to 2.1 m (7 feet)

Environmental adaptability (working) – Temperature: -20~+60 ° C (-4~+140 ° F);

-Humidity: 5% to 95% (without condensation);

-Altitude: -300 to+3000 meters;

-Pollution level: G3 level (harsh environment, compliant with ISA S71.04)

Environmental adaptability (storage) – Temperature: -40~+70 ° C (-40~+158 ° F);

-Altitude: -300 to+12000 meters

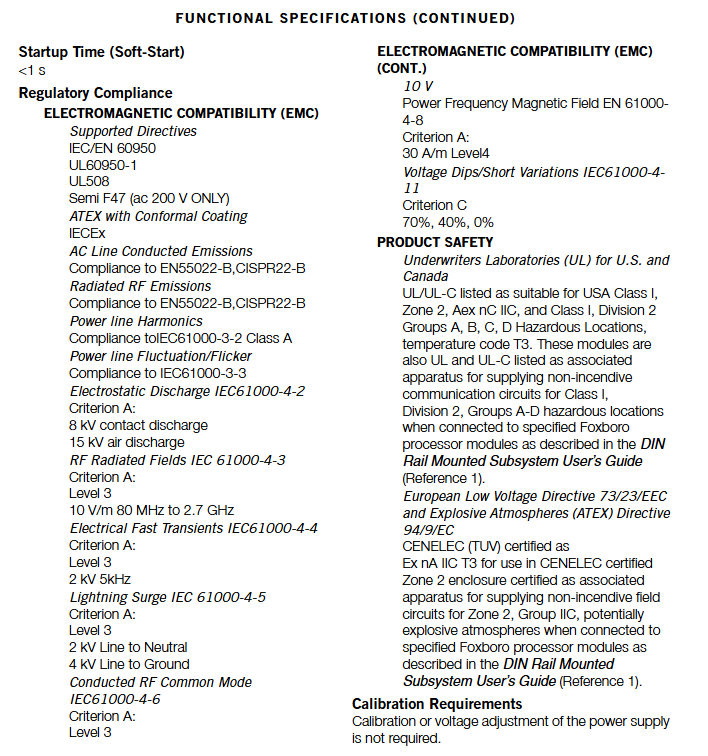

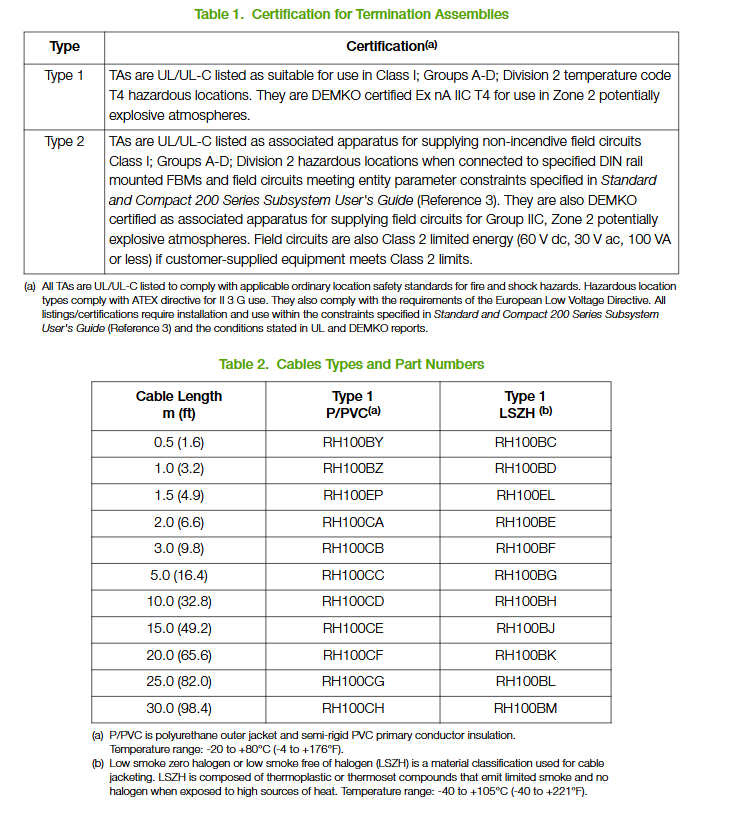

Compliance Certification – EMC: Compliant with EN61326:2013 Class A emission/industrial immunity (EU Directive 2014/30/EU);

-Safety: UL/UL-C Class I Div 2 (Groups A-D, T4)、ATEX Ex nA IIC T4 Gc;

-Classification: ABS/French BV certification (EC31, except for some models);

-Environmental Protection: Compliant with RoHS 2011/65/EU (non RoHS model labeling)

(2) Physical and installation specifications

Specification category parameter details

Installation method – DIN rail: compatible with horizontal/vertical installation (keeping the substrate in a horizontal position);

-Cabinet installation: 19 inch rack (requires P0930AS installation kit, depth 25.4mm)

Weight (excluding modules) -2-position substrate: approximately 0.5 kg (1.1 lb);

-8-bit substrate: maximum 0.91 kg (2.0 lb)

Key dimensions (example) -2-digit vertical substrate: height 120.3 mm, width 240.0 mm;

-8-bit horizontal substrate: length 453.0 mm, height 216.0 mm (including optional terminal components)

Materials and Protection – Shell: PC+ABS (UL94 V0 flame retardant);

-Rail fasteners: made of steel (quantity varies with substrate size);

-Color: Black

Key points for installation and maintenance

(1) Module installation rules

Redundant module layout:

Redundant FBM/FCM needs to occupy adjacent odd/even slot pairs (such as 1-2, 3-4 bits);

FCP/FDC/FEM/FBI redundancy requires the use of a dedicated 2-position substrate and cannot be mixed with other modules.

Non redundant module limitation:

Non redundant FCM needs to occupy a pair of slots (adjacent slots are vacant);

FBM can be installed in any vacant slot (matching substrate support type).

(2) Key accessories and connections

Accessory type, function, typical model

Fieldbus splitter/terminator – Termination bus signal: RH916RB (replacing P0916RB);

-Split A/B bus+time synchronization: RH926KW (non FCP280), RH924ZJ (FCP280 port 1);

-Connect 100 Series FBM: RH926LC (replacing P0926LC) RH916RB, RH926KW, RH928CV (FCP280 extension)

Connect the power cable between the FPS series power supply (such as FPS480-24) and the substrate:

– RH100DZ(0.6 m)、RH100EA(1.0 m) RH100DZ、RH100EA、RH100EB(2.1 m)

Substrate installation kit 19 inch rack installation: including bracket and fasteners P0930AS

(3) Maintain convenience

Hot swappable support: FCP, FEM, FCM, FBI, FBM can all be plugged and unplugged online without disconnecting field cables, power supplies, or communication buses;

Fault diagnosis: Clearly labeled connector functions (power/fieldbus/I/O) on the substrate, combined with module LED indicator lights (such as power and communication status), can quickly locate faults;

Online expansion: Under the redundant bus architecture, when adding FBM support substrates, only A/B bus splitters need to be connected without shutting down.

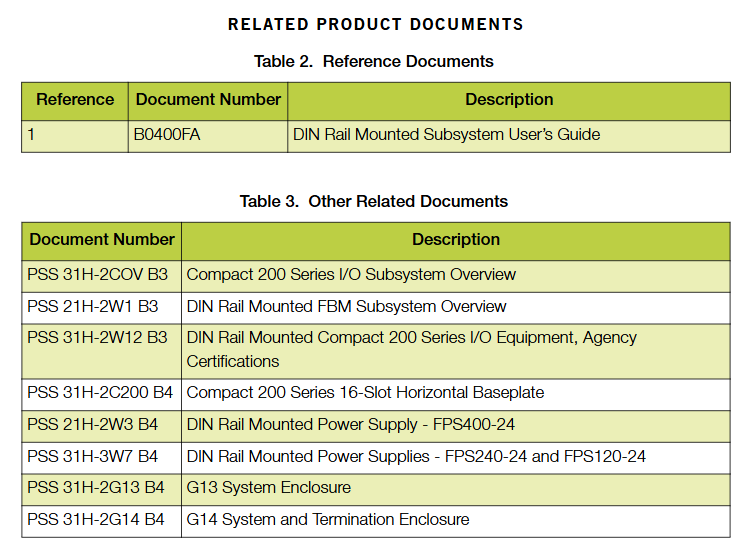

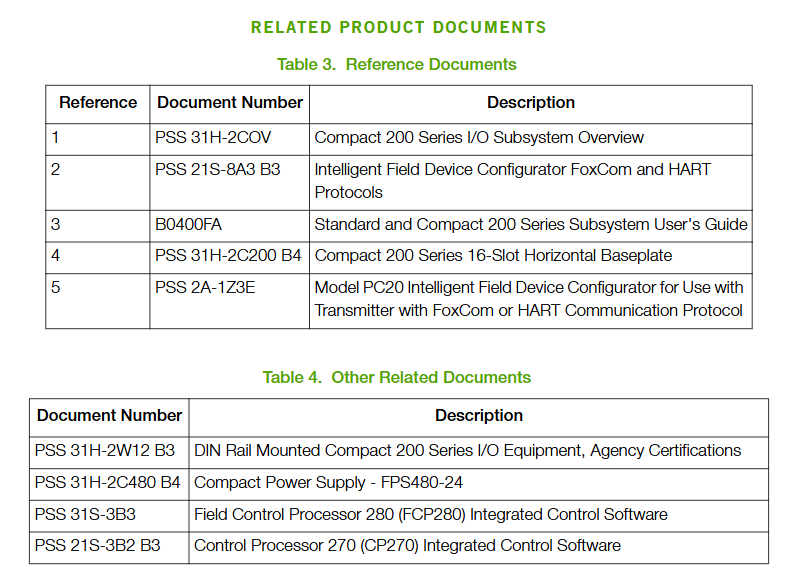

Related reference documents and support

Document type Document number/name Core purpose

Subsystem Overview PSS 31H-2SOV (Standard 200 Series), PSS 31H-2COV (Compact 200 Series) System Architecture and Substrate Matching Rules

Module specifications PSS 31H-1FCP280 (FCP280), PSS 31H-2FDC280 (FDC280) module and substrate adaptation details

User Guide B0400FA (Standard and Compact 200 Series Subsystem User’s Guide) Installation, Wiring, and Troubleshooting Steps

Substrate configuration for hazardous area applications of PSS 31H-2Y12 (ISTA-BP Intrinsic Safety Terminal Substrate) related to intrinsic safety