Siemens 6AV6642-0DA01-1AX1 SIMATIC OP177B (HMI)

Product positioning and core identification

6AV6642-0DA01-1AX1 is the OP177B industrial human-machine interface (HMI) under the Siemens SIMATIC series, designed specifically for industrial automation scenarios. Its core function is to enable visual interaction between operators and controllers (such as PLCs), supporting parameter settings, process monitoring, alarm recording, and other operations. It is compatible with various fields of equipment such as discrete manufacturing and process control (such as machine tools, production lines, control cabinets).

Core hardware specifications

1. Display and operation unit

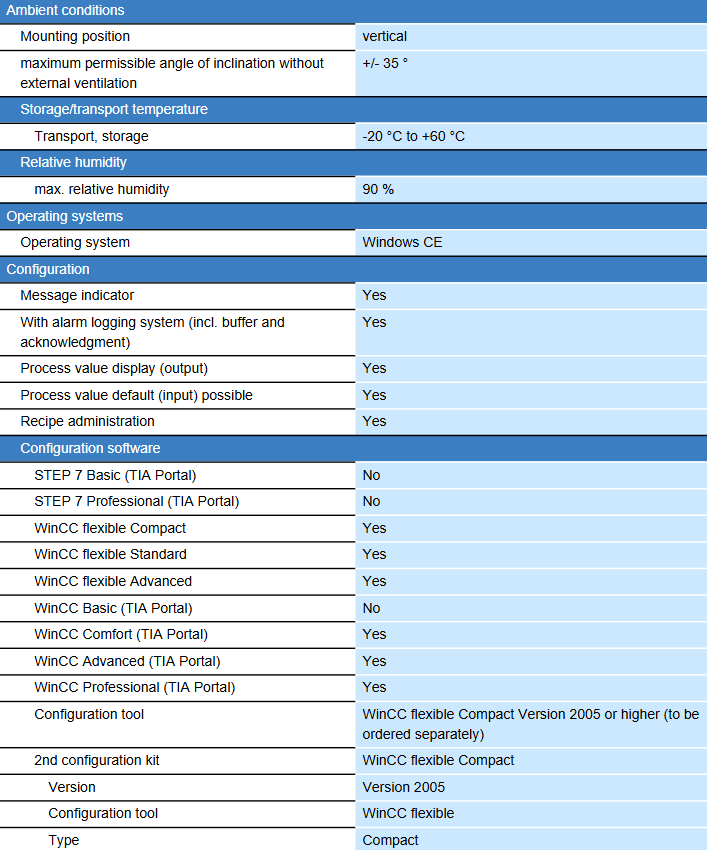

Category specific parameters

Display screen 5.7-inch STN color screen, resolution 320 × 240 pixels, supports 256 color display; Screen size 120mm × 90mm

The average time between failures (MTBF) of the backlight in a 25 ℃ environment is about 50000 hours, meeting the long-term industrial operation requirements

Dual operation mode: thin film keyboard+analog resistive touch screen, balancing precise input and fast operation

32 programmable function keys (including 26 keys with LED status indicators) are configured for key configuration, supporting numeric/alphabetical/hexadecimal input and multiple key simultaneous operation

Expand input with one USB interface, which can be connected to a mouse, keyboard, or barcode reader to enhance data input flexibility

2. Processor and Storage

Processor: ARM architecture, with a main frequency of 200 MHz, ensuring interface response and data processing speed;

Storage type: Flash flash+RAM memory, available storage space for user data is 2048 KB;

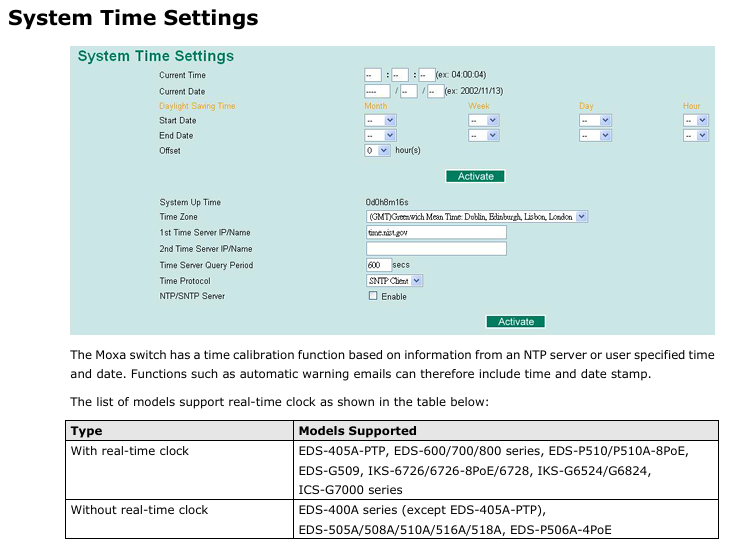

Clock module: hardware clock, supports synchronization function, but does not have battery backup (time needs to be recalibrated after power failure);

Extended storage: Supports MMC/SD card expansion (requires E version 016 and above, and comes with WinCC flexible 2008 SP1 software).

3. Power supply and power consumption

Power supply voltage: 24 V DC (industrial standard DC power supply, compatible with control cabinet power supply);

Rated current: 0.24 A;

Impulse current: 0.5 A ² · s (to avoid impact on the power system when powered on).

4. Protection level and installation

Protection performance: Positive protection level IP65, NEMA 4x/12 (dustproof and splash proof after installation, suitable for humid/dusty environments such as workshops); Back protection level IP20 (to be installed inside the control cabinet to avoid direct exposure);

Installation method: Vertical installation, maximum allowable tilt angle ± 35 ° (without external ventilation conditions);

Physical dimensions: Front dimensions 243 mm × 212 mm, weight approximately 1 kg, suitable for standard control cabinet opening installation.

Communication interface and protocol

1. Interface configuration

Number and specifications of interface types

Industrial Ethernet 1 RJ45 interface, maximum transmission rate of 12 Mbit/s, supports industrial grade network communication, with status indicator light

RS485/RS422 1 RS485 interface+1 RS422 interface, supports serial communication, compatible with traditional industrial equipment (such as frequency converters, instruments)

RS232 optional, expand serial communication capability as needed

USB 1 USB interface, used for external device connection or data transfer

The printer interface supports printer connection and can print documents such as alarm records and shift handover reports

2. Support protocol and controller compatibility

Core protocols: MPI (Multipoint Interface), PROFIBUS-DP (Industrial Fieldbus), PROFINET (Industrial Ethernet) Sm@rtServer agreement;

Compatible controller:

Siemens series: S5, S7-200, S7-300/400, Win AC, SINUMERIK (numerical control system), SIMOTION (motion controller);

Third party brands: Allen Bradley (DF1 protocol), Mitsubishi (FX series), Telemecanique (ADJUST/Uni Always protocol), Modicon (Modbus protocol), etc., compatible with multi vendor automation systems;

Communication function: Supports configuration file upload/download (via MPI/PROFIBUS DP, serial, etc.) USB、 Ethernet or external storage media), supporting automatic transmission recognition.

Software configuration and functionality

1. Software configuration requirements

Siemens specialized HMI configuration software is required, supporting the following versions:

Basic configuration: WinCC flexible Compact 2005 and above versions (need to be ordered separately) WinCC flexible Standard/Advanced;

TIA Portal compatibility: Supports WinCC Comfort/Advanced/Professional (TIA Portal environment), does not support STEP 7 Basic/Professional or WinCC Basic;

Core tool: Implement interface design, variable association, alarm configuration and other functions through WinCC flexible software, supporting project template and library file reuse.

2. Core functions and performance

(1) Monitoring and Display

Screen configuration: Supports up to 500 configurable screens, supports permanent/default windows, customizable startup screen, supports screen switching through PLC control, and screen numbers can be displayed on the screen;

Object elements: Each project supports up to 500 objects, each screen supports 5 dynamic objects (such as trend chart, bar chart, slider, analog display, hidden button), supports 2500 text elements, 30 date/time fields, 500 icons (including 50 full screen icons);

Variable management: A single device supports 1000 variables, each screen supports 50 variables, supports initial and limit value settings, supports variable multiplexing, but does not support structural variables;

Process value display: Supports displaying process values in numerical, textual, and graphical formats (such as bar charts and trend charts), with a maximum of 5 data bars per trend chart and support for displaying limit lines.

(2) Alarm and Log

Alarm management: supports 2000 bit messages and 50 analog messages, up to 32 alarm categories, and supports 99 confirmation groups;

Log function: with alarm buffer and confirmation mechanism, supporting alarm log printing (including color printing and hard copy), supporting shift report generation (handover report);

Message configuration: Each message has a maximum length of 80 characters, supports displaying 8 process values in association, and supports system messages (HMI self status) and PLC messages (controller fault/status).

(3) Formula management

Formula capacity: Supports up to 100 formulas, with each formula containing 200 data records and each data record containing 200 entries;

Storage Expansion: Basic recipe storage of 32 KB (integrated with Flash), expandable storage capacity through MMC/SD card, suitable for multi product production scenarios (such as quick switching of process parameters for different specifications of products).

(4) Security and Permissions

User management: supports 50 user groups, 32 user permission levels, and can assign operational permissions according to roles (such as operators can only monitor, administrators can modify parameters);

Password function: Supports password import/export, records up to 1000 password error attempts, and enhances system security.

Environmental adaptability and certification

1. Environmental parameters

Working temperature: not clearly indicated, refer to storage/transportation temperature (-20 ℃~+60 ℃), suitable for most industrial workshop environments (extreme high/low temperatures should be avoided);

Relative humidity: maximum 90% (non condensing, to avoid circuit faults caused by moisture);

Transportation/storage temperature: -20 ℃~+60 ℃, meeting the needs of logistics transportation and warehouse storage.

2. Compliance certification

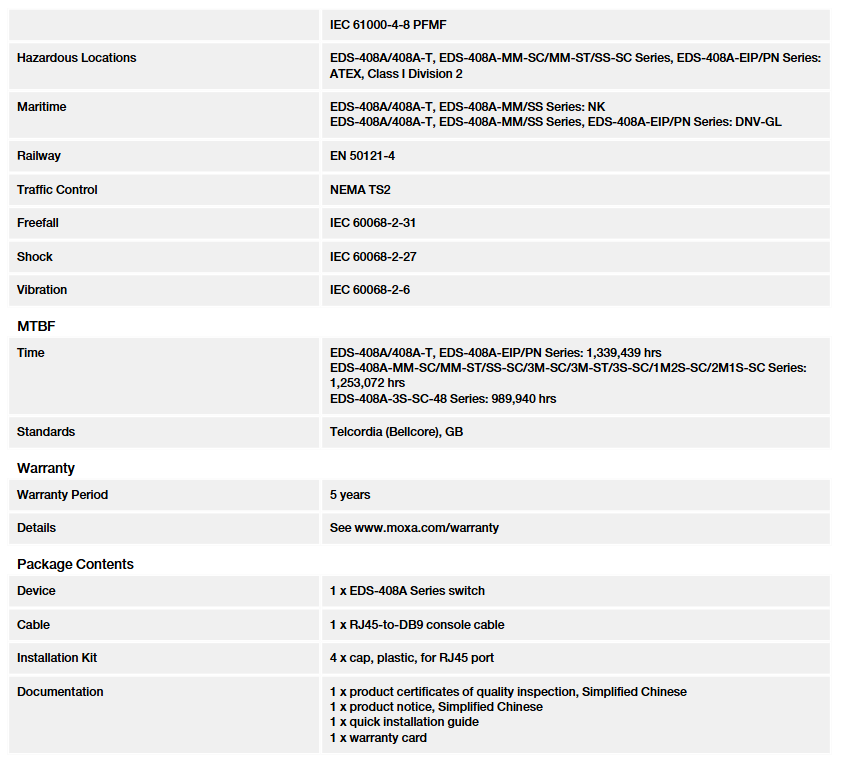

This product has passed multiple international industrial certifications and is suitable for applications in multiple regions around the world

Safety certification: CE, UL, CSA, cULus;

Hazardous environment certification: FM Class I Div. 2, EX Zone 2/22 (can be used in non explosion proof areas such as chemical, oil and gas hazardous areas);

Classification certification: GL, ABS, BV, DNV, LRS (some models support, can be used for ship automation systems);

Electromagnetic compatibility: Complies with industrial EMC standards, has strong anti-interference ability, and is suitable for complex electromagnetic environments (such as workshops with dense motors).