Foxboro ™ DCS FBM214b HART ® Communication

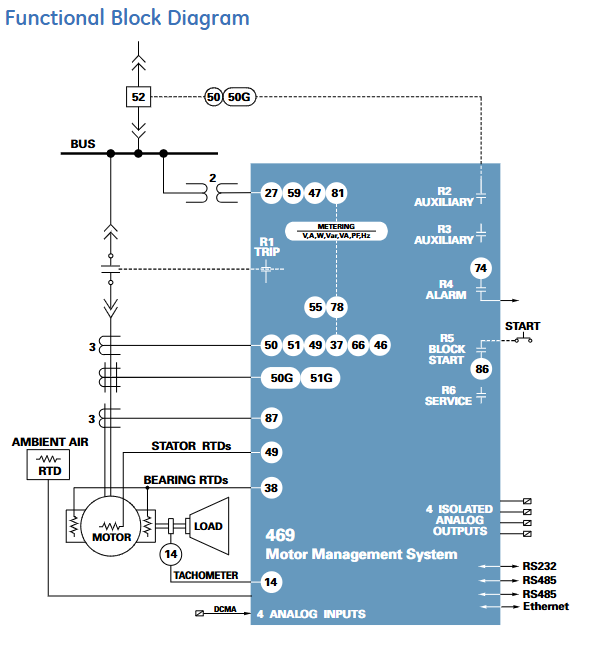

Product Overview and Core Positioning

FBM214b is an 8-channel independent isolated analog input module, with the core function of implementing Foxboro ™ DCS and “Standard 4-20mA Analog Equipment” and “HART ® The bidirectional communication and data acquisition of protocol digital devices can be compatible with mixed access of two types of devices without additional hardware. It is positioned as an integrated acquisition center for analog signals and HART digital signals, suitable for industrial scenarios that require simultaneous acquisition of device analog and digital diagnostic information (such as sensor and transmitter data acquisition in process control).

Core functions

Signal compatibility: All 8 channels support two types of input signals and can be mixed and configured

Standard 4-20mA analog sensor signal;

HART superimposed on 4-20mA analog signal ® Frequency Shift Keying (FSK) digital signal.

HART communication capability: As the host of HART field devices, it can receive 2 digital messages per second from the field devices, supporting HART universal commands, common commands, and device specific commands (which need to be implemented through Foxboro DCS Field Device Expert for HART tool), but does not support burst communication mode.

Power supply flexibility: Each channel is equipped with an independent isolated power supply, which can be powered internally or externally (when using an external power supply, a Cable Balun module is required to prevent crosstalk).

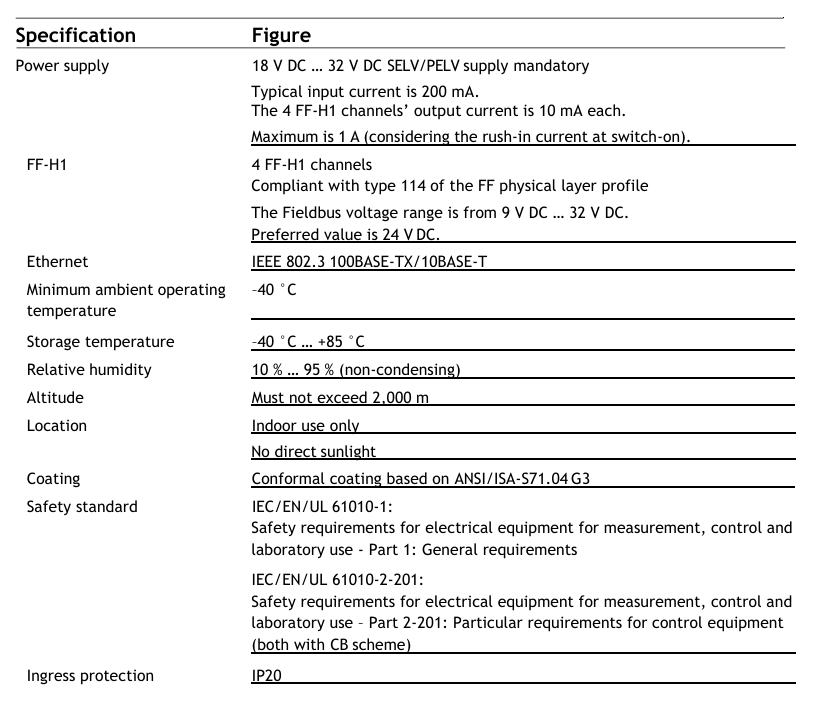

Basic compatibility: It needs to be compatible with I/A Series software v8.2-v8.8 or Control Core Services v9.0 or above, and connected to the Fieldbus Communication Module (FCM) or Control Processor (FCP) through a redundant 2Mbps fieldbus.

Key features and technological advantages

1. Core Features

Specific description of characteristic categories

Isolation protection is achieved between 8 channels, between channels and ground, and between channels and module logic circuits, with * * galvanic isolation (electrical isolation) * *. It can withstand 600VAC common mode voltage for 1 minute (without damage), avoiding signal interference and equipment damage.

High precision acquisition uses Sigma Delta (∑ – Δ) converters, with analog input values updated every 100 milliseconds for each channel to ensure data acquisition accuracy.

The environmental adaptability shell is made of extruded aluminum material, which is suitable for harsh environments and meets the * * Class G3 (harsh) environmental * * requirements of ISA standard S71.04. It supports industrial scenarios such as dust and humidity fluctuations.

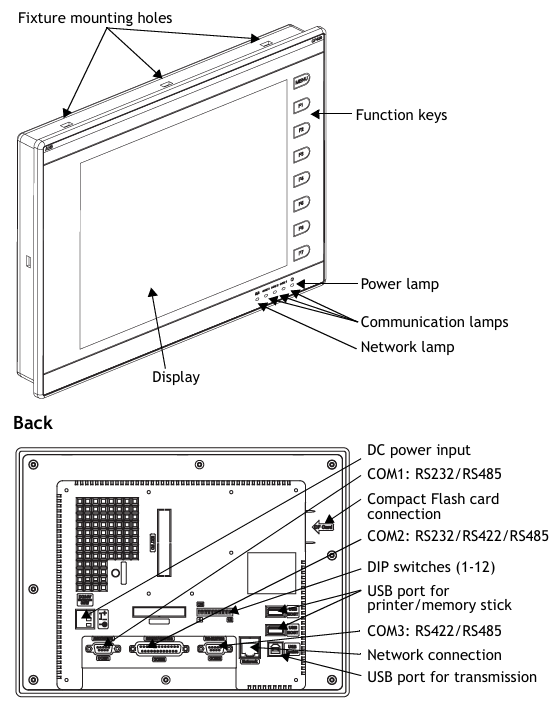

Maintenance convenience supports “hot plugging”, which means that when replacing modules, there is no need to disconnect on-site wiring, power or communication cables; The front LED indicator light can visually display the module’s operating status and channel communication activity.

Redundant access to 2Mbps fieldbus (A/B dual path), automatically switches to another path in case of a single path failure, ensuring uninterrupted communication.

2. Special component: Cable Balun module

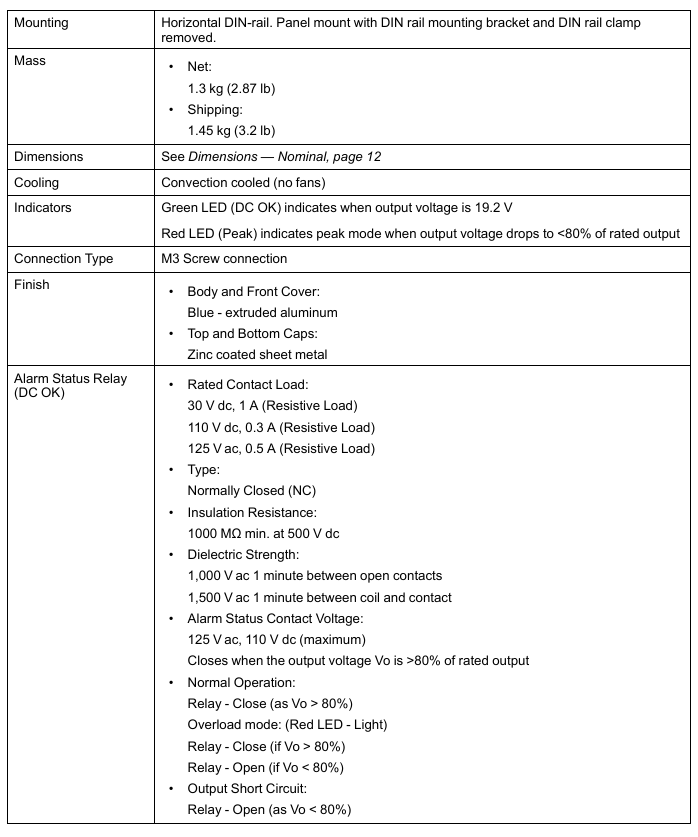

When multiple channels are powered by an external common power source, a Cable Balun module is required to maintain the balance of the HART communication line and prevent near end crosstalk (this module is not required for internal power supply channels). The core parameters are as follows:

Specific specifications of component information

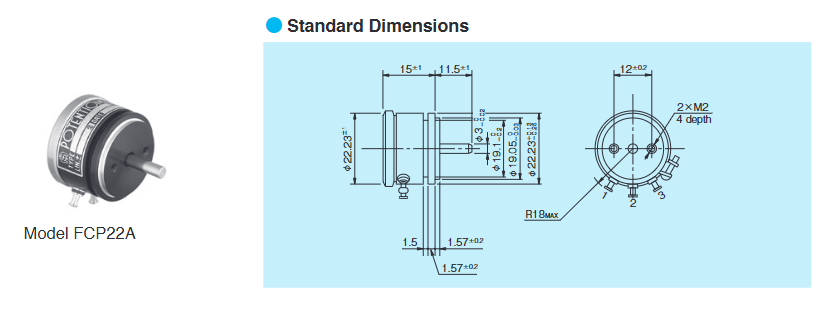

Model CBM-4

Part number RH903SV

Each module contains 4 Balun units, with 1 unit corresponding to 1 external power supply circuit. The maximum increase in circuit resistance is 30 Ω

Installation requirements require the use of intrinsic safety barriers (such as MTL 787S+) to limit line energy in hazardous environments; External power supply can be connected in parallel with redundant power supply. It is recommended to cross connect the capacitor provided by the user to filter out AC power

Functional and Performance Specifications

1. Channel and communication parameters

Parameter category specific specifications

HART device compatibility supports HART ® Devices with protocol v5, v6, v7 versions

External power supply for input resistor (including terminal components): 282 Ω; Internal power supply: 302 Ω

The internal power supply channel of the circuit power protection is designed with a current limit of less than 37mA to avoid overcurrent damage

Internal power supply output 24VDC ± 10%, output impedance 20 Ω (including terminal components)

Fieldbus communication redundancy 2Mbps fieldbus, bidirectional communication with FCM/FCP

2. Power supply and power consumption

Power parameter specifications

Input voltage (redundant) 24VDC, allowing+5%/-10% fluctuation

Maximum power consumption 8.4W

Maximum heat dissipation 5.6W

3. Calibration requirements

Modules and terminal components (TA) do not require regular calibration, and precision calibration has been completed at the factory, reducing maintenance workload.

Hardware and installation specifications

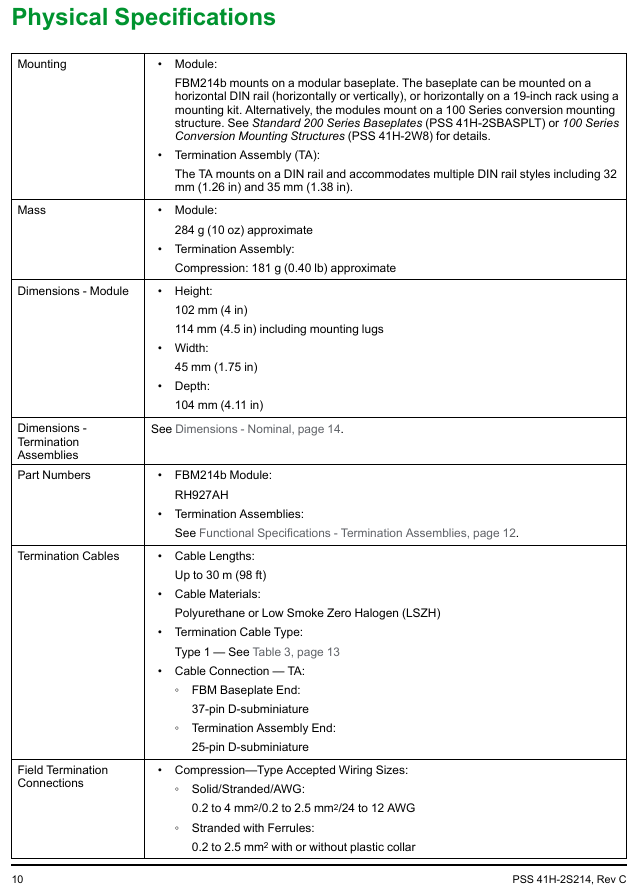

1. Core hardware components

Component type, model/part number, key parameters

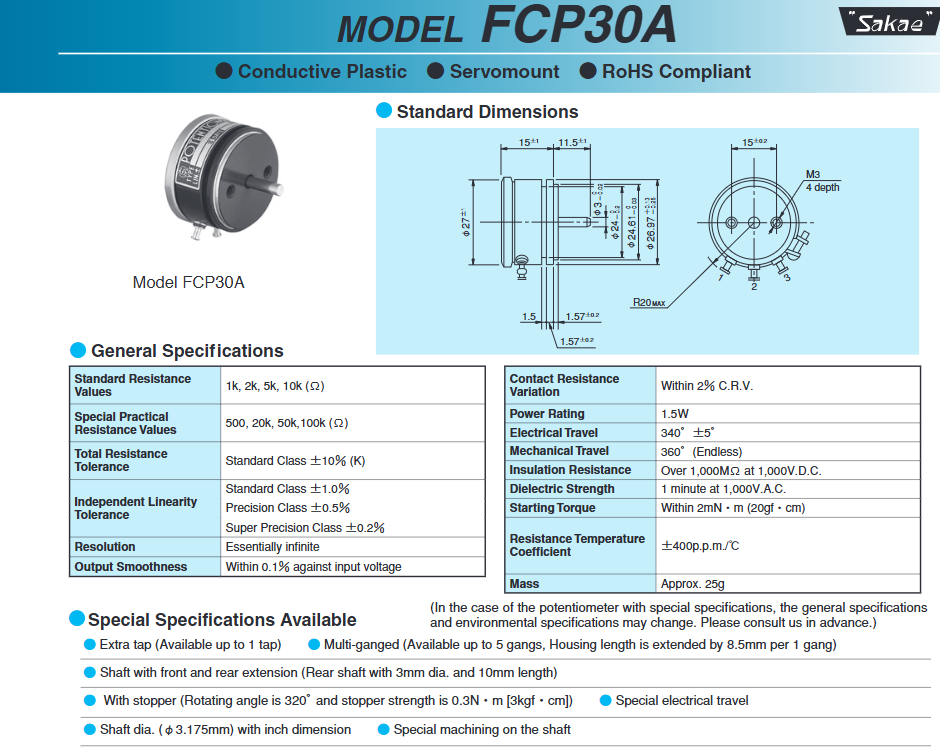

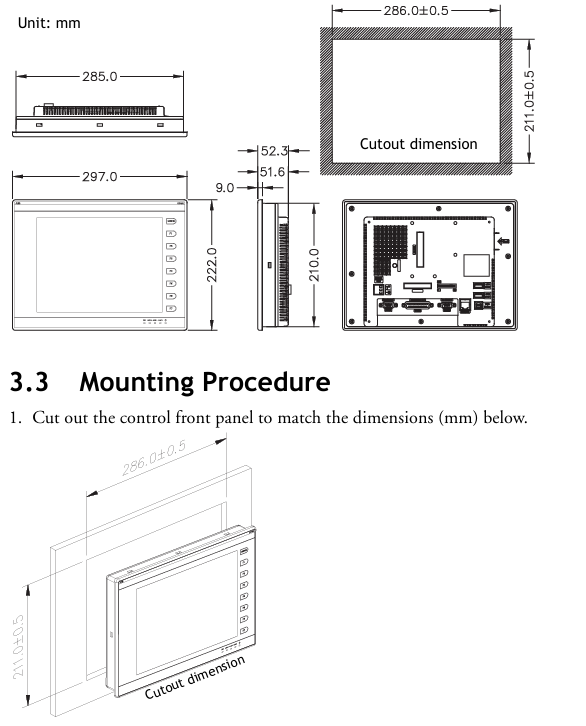

FBM214b module RH927AH weight: approximately 284g (10oz); Dimensions: Height 102mm x Width 114mm (including installation ears) x Depth 45mm (or Depth 104mm, depending on configuration)

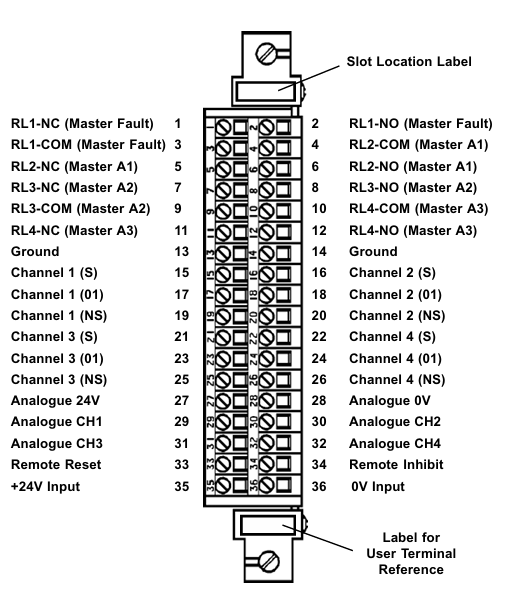

Terminal Component (TA) RH924JH Material: Polyamide (PA, -20~70 ℃ temperature resistance); Wiring type: compression terminal; Weight: Approximately 181g (0.40lb)

Terminal cables are made of two materials (polyurethane/PVC, low smoke halogen-free LSZH), with a length of 0.5-30m (1.6-98ft), such as RH916DA (0.5m polyurethane) RH928AA(0.5m LSZH)

Cable connection module side: 37 pin D-subminiature interface; TA side: 25 pin D-subminiature interface

2. Installation requirements

Specific requirements for installation category

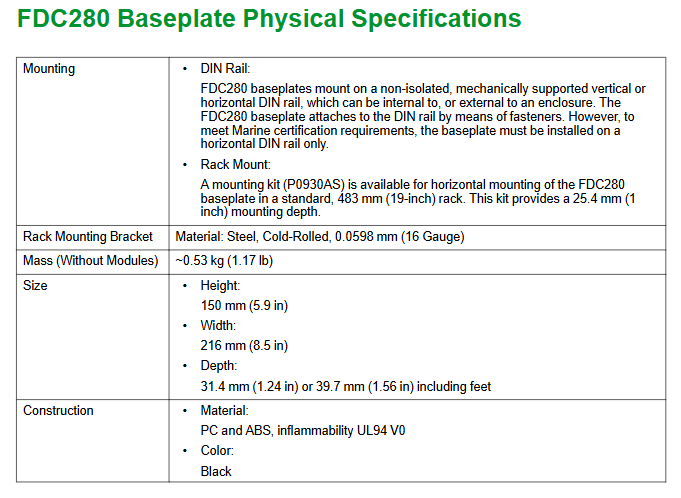

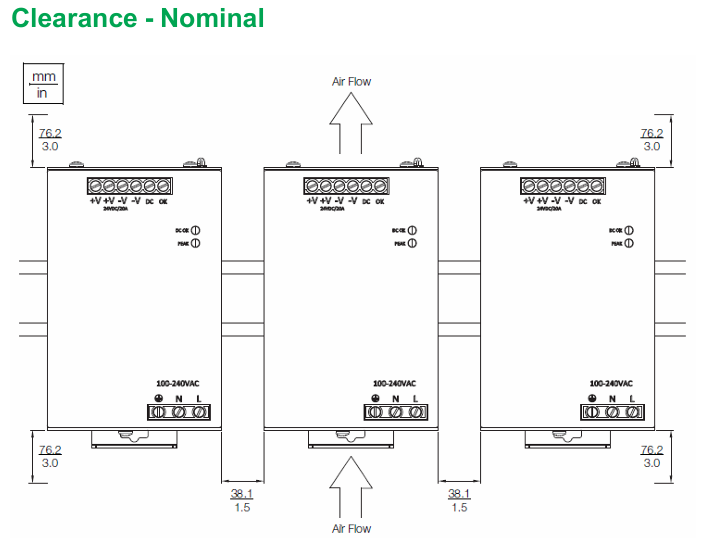

The module installation needs to be installed on a modular base plate, which supports horizontal/vertical DIN rail installation or can be adapted to a 19 inch rack through an installation kit; It can also be installed on the 100 series conversion installation structure (refer to PSS 41H-2W8)

TA is installed on 32mm or 35mm DIN rails and can be installed in the same cabinet or adjacent cabinets as the module (with a maximum cable length of 30m)

Wiring specifications support solid/multi strand wires (0.2~4mm ²/24~12AWG), multi strand wires with wire ears (0.2~2.5mm ², compatible with or without plastic sleeves)

Environmental and Compliance Specifications

1. Environmental parameters

Environment category, operating conditions, storage conditions

Temperature module/TA: -20~70 ℃ (-4~158 ℉) -40~70 ℃ (-40~158 ℉)

Relative humidity 5%~95% (no condensation) 5%~95% (no condensation)

Altitude -300~3000m (-1000~10000ft) -300~12000m (-1000~40000ft)

The anti pollution level complies with ISA S71.04 Class G3 and has passed the EIA 364-65 Class III exposure test-

Anti vibration 0.75g (5~500Hz)-

2. Compliance certification

Specific standards for certification categories

Electromagnetic compatibility (EMC) complies with EU directives 2004/108/EC (before April 20, 2016), 2014/30/EU (after April 20, 2016), and meets EN61326-1:2013 Class A (emission and industrial immunity)

Product Safety – UL/UL-C Certification in the United States/Canada: Suitable for cabinet systems with Class I A-D Group 2, T4 temperature code;

-EU Low Voltage Directive 2006/95/EC (before April 20, 2016), 2014/35/EU (after April 20, 2016);

-EU ATEX Directive 94/9/EC (before April 20, 2016), 2014/34/EU (after April 20, 2016): DEMKO certified Ex nA IIC T4 for Zone 2 hazardous environments

Environmental compliance complies with the EU RoHS Directive 2011/65/EU and revised versions 2015/863, 2017/2102

International Certification IECEx Certification

California Proposition 65 products contain lead and lead compounds, which may cause cancer or reproductive harm. For more information, please refer to www.P65Warning.ca.gov

Terminal Component (TA) and Cable Configuration

1. TA core parameters (RH924JH)

Specific specifications for TA

Adapt signal 8-channel 4-20mA analog signal/HART digital signal

Authentication Type 1+Type 2 Dual Authentication:

-Type 1: UL/UL-C Class I A-D Group 2 T4, ATEX Ex nA IIC T4 2;

-Type 2: UL/UL-C associated equipment (non flammable field circuit), ATEX IIC Zone 2 associated equipment, meets Class 2 current limiting requirements (below 60VDC/30VAC/100VA)

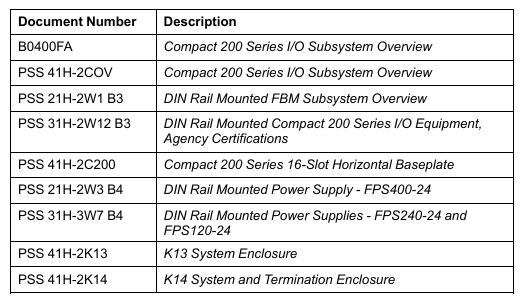

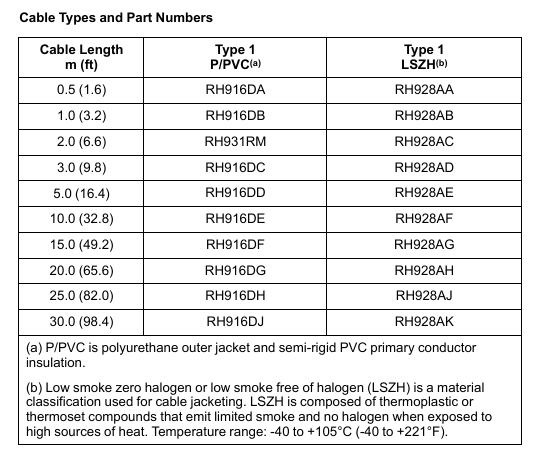

2. Terminal cable selection

Cables are divided into two categories: “Polyurethane/PVC (Type 1 P/PVC)” and “Low Smoke Zero Halogen (Type 1 LSZH)”. The latter is suitable for scenarios that require smoke toxicity and corrosiveness (such as subways and data centers). The commonly used lengths and part numbers are as follows:

Length (m/ft) Type 1 P/PVC Part Number Type 1 LSZH Part Number

0.5/1.6 RH916DA RH928AA

1.0/3.2 RH916DB RH928AB

2.0/6.6 RH931RM RH928AC

3.0/9.8 RH916DC RH928AD

5.0/16.4 RH916DD RH928AE

10.0/32.8 RH916DE RH928AF

15.0/49.2 RH916DF RH928AG

20.0/65.6 RH916DG RH928AH

25.0/82.0 RH916DH RH928AJ

30.0/98.4 RH916DJ RH928AK