Honeywell CR-6A Six Relay Control Module

Product specifications

Normal operating voltage: 15-32 VDC

Standby current: 1.45 mA

Alarm current: 32 mA (assuming all six relays have switched once and all six LEDs are continuously on)

Temperature range:

ULC application: 32 ° F to 120 ° F (0 ° C to 49 ° C)

EN54 application: -10 ° C to 55 ° C

Humidity:

ULC application: 10% to 95%, non condensing

EN54 application: 10% to 93%, non condensing

Size: 6.8 inches high x 5.8 inches wide x 1.0 inches deep (173mm high x 147mm wide x 25mm deep)

Maximum IDC wiring resistance: 40 ohms

Accessories: BB-2A cabinet, BB-6A cabinet, CH-6A chassis, or appropriately grounded metal cabinet

Wire gauge: 12-18 AWG (0.9mm ² -3.25mm ²)

Relay current: 30 mA/relay pulse (15.6ms pulse duration, under panel control)

Preparation before installation

This information is only provided as a quick reference installation guide. If modules are installed in the existing operating system, operators and local authorities should be notified that the system will be temporarily suspended.

Disconnect the power supply of the control panel before installing the module.

This system contains static sensitive components. Before handling any circuit, it is necessary to ground it with a suitable wrist strap to eliminate static charges on the body.

The enclosure cabinet should be made of metal material and properly grounded.

This manual should be left to the owner/user of this device.

Product overview

Purpose: Suitable for intelligent alarm systems, used for Form-C switching applications, load circuits do not require wiring monitoring.

Structure: Each module provides a set of independent dry-type relay contacts, which can be wired as normally open or normally closed; Each module has its own address, and the address of the first module is set to 01 to 94 through a pair of rotary encoding switches. The remaining modules are automatically assigned to the next five higher addresses; Disable up to three unused modules to release addresses for use elsewhere; Each CR-6A module also has a green LED indicator light controlled by the panel, which can make the LED flash, lock on or lock off.

Includes: 6 1 × 3 terminal blocks, 1 1 × 4 terminal block, 2 1.25-inch (32mm) supports, 3 mechanical screws, 1 splitter (note: in the disabled position, a maximum of one splitter can be installed at the same time)

Compatibility requirements

To ensure normal operation, this module should only be connected to compatible control panels.

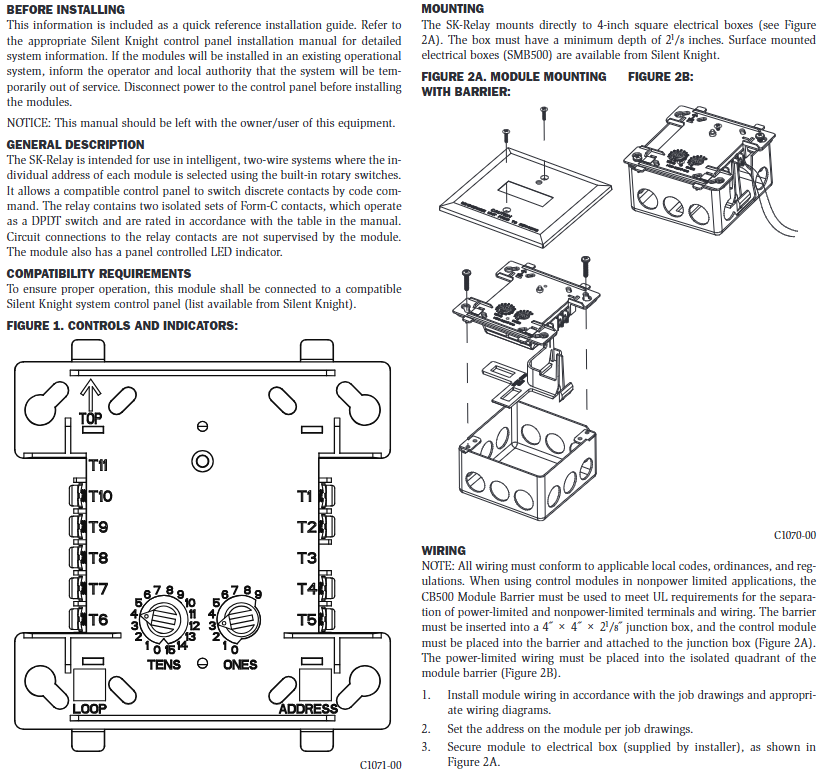

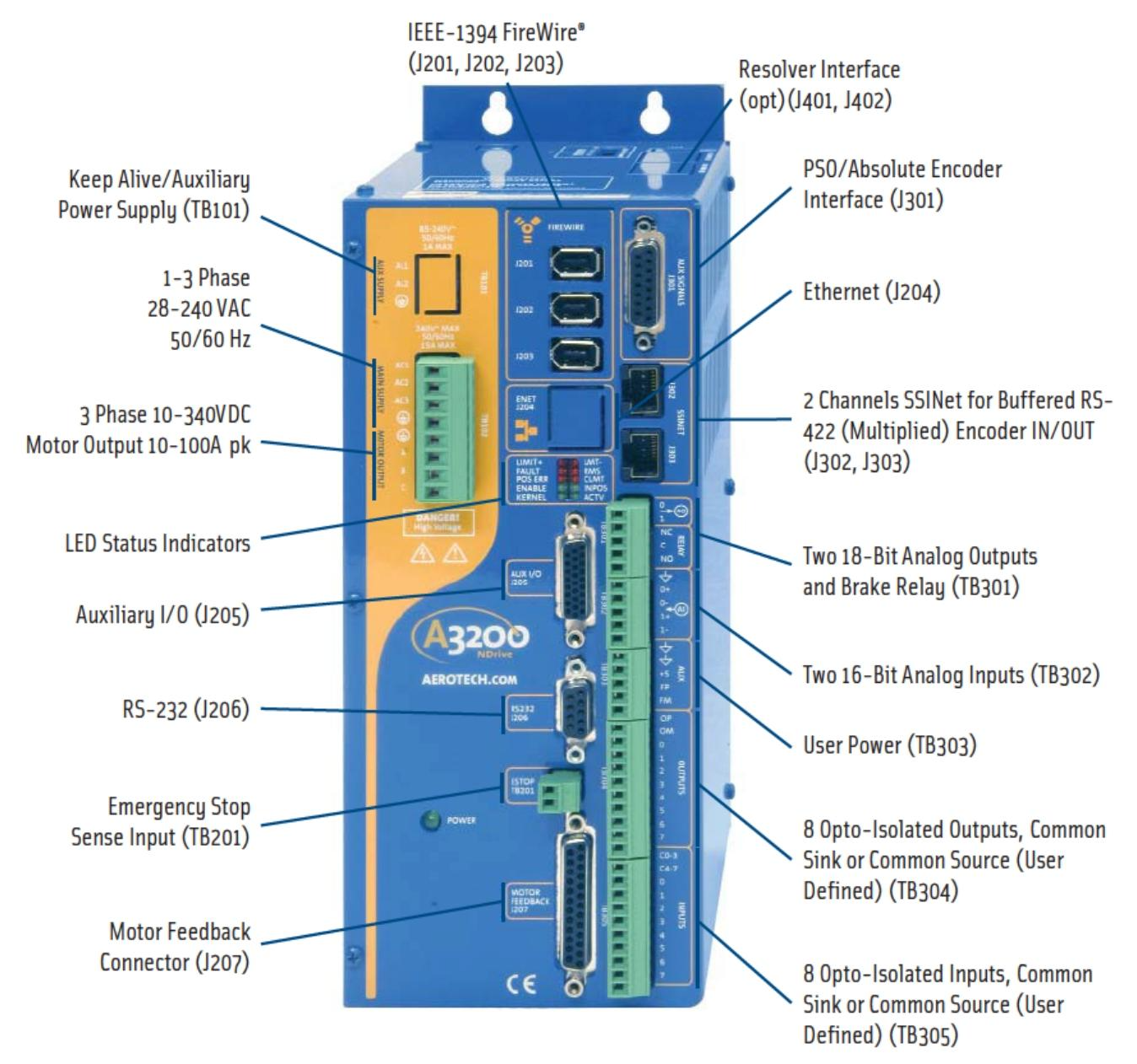

Component

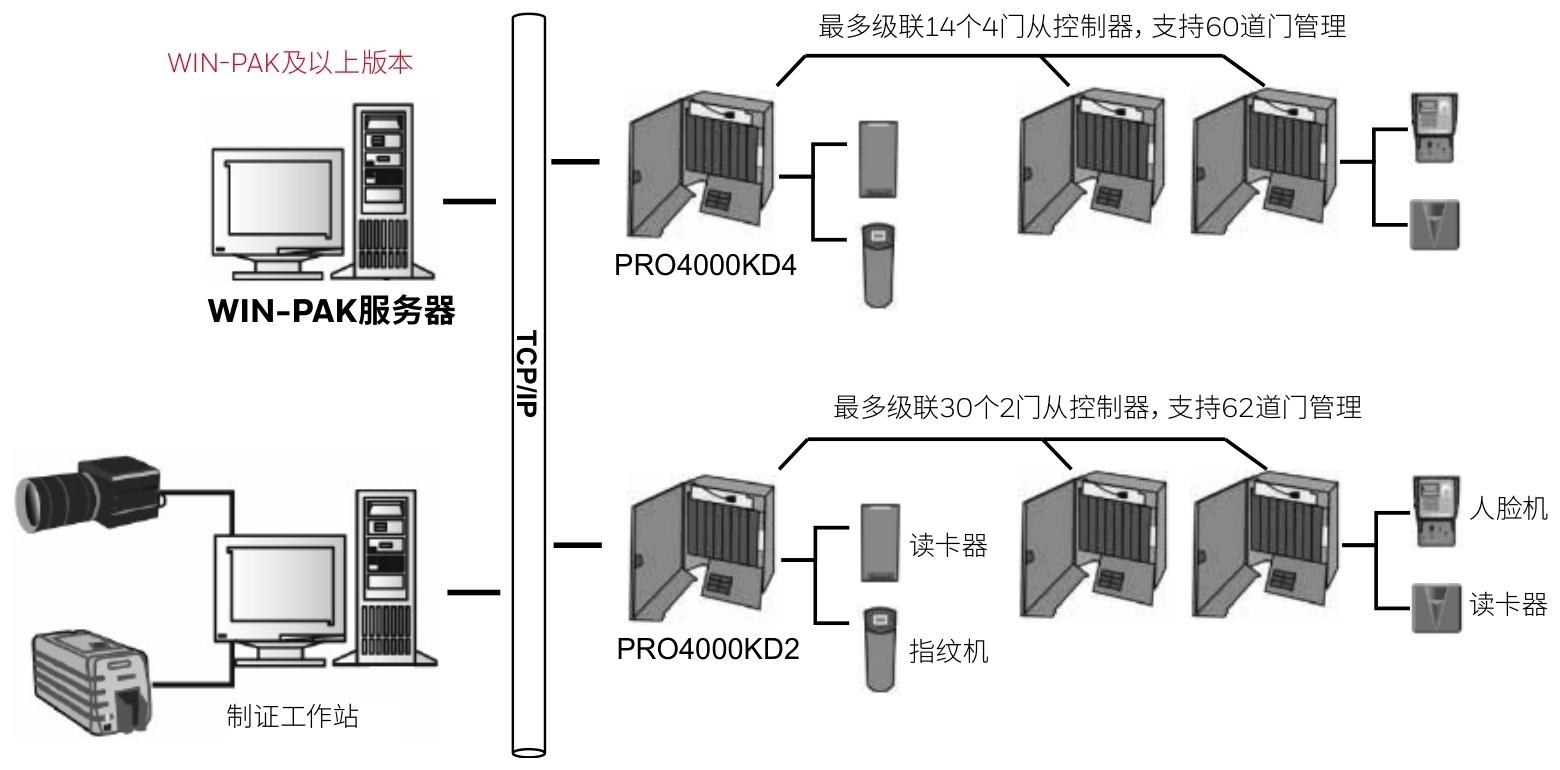

Installation options:

Up to six CR-6A modules can be installed on the CH-6A of the BB-6A cabinet

One or two CR-6A modules can be installed in the BB-2A cabinet

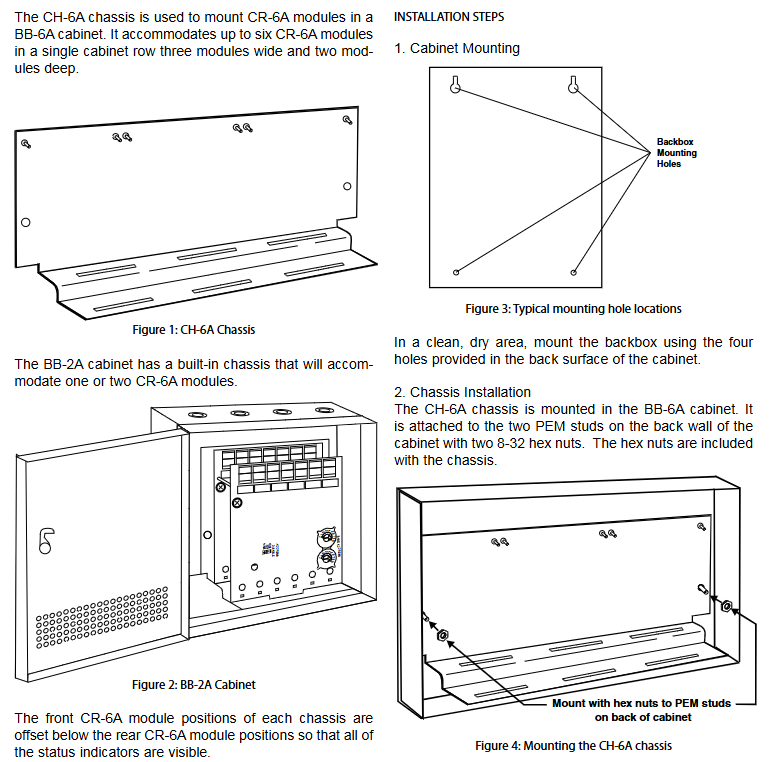

Chassis: CH-6A chassis is used to install CR-6A modules in the BB-6A cabinet. It can accommodate up to six CR-6A modules in a single cabinet row, three modules wide and two modules deep; The BB-2A cabinet has a built-in chassis that can accommodate one or two CR-6A modules. The front CR-6A module position of each chassis is lower than the rear CR-6A module position, so that all status indicators are visible.

Cabinet: BB-6A cabinet can accommodate CH-6A chassis with up to six CR-6A modules installed; The BB-2A cabinet accommodates one or two CR-6A modules on its internal chassis, and the cabinet dimensions refer to the cabinet installation document.

Installation steps

Cabinet installation: Install the bottom box using the four holes provided on the back of the cabinet in a clean and dry area.

Chassis installation: The CH-6A chassis is installed in the BB-6A cabinet and secured to the two PEM bolts on the rear wall of the cabinet with two 8-32 hex nuts, which are provided with the chassis; The BB-2A cabinet comes with an installed chassis and does not require additional installation.

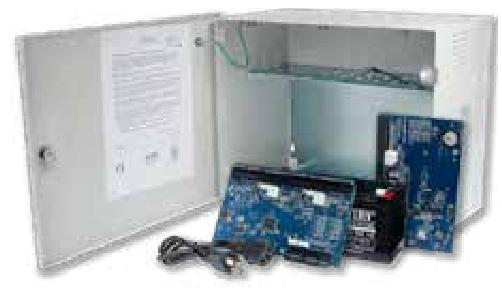

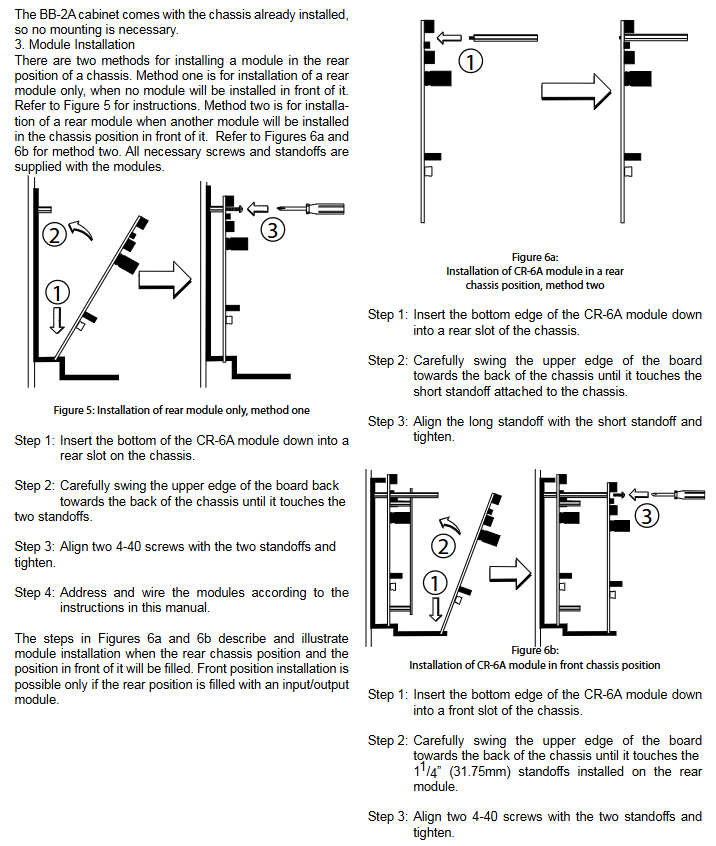

Module installation: There are two methods to install modules at the rear of the chassis.

Method 1: Install only the rear module and do not install any modules in front of it.

Method 2: Install the rear module, and another module will be installed in front of it. All necessary screws and supports are provided with the module.

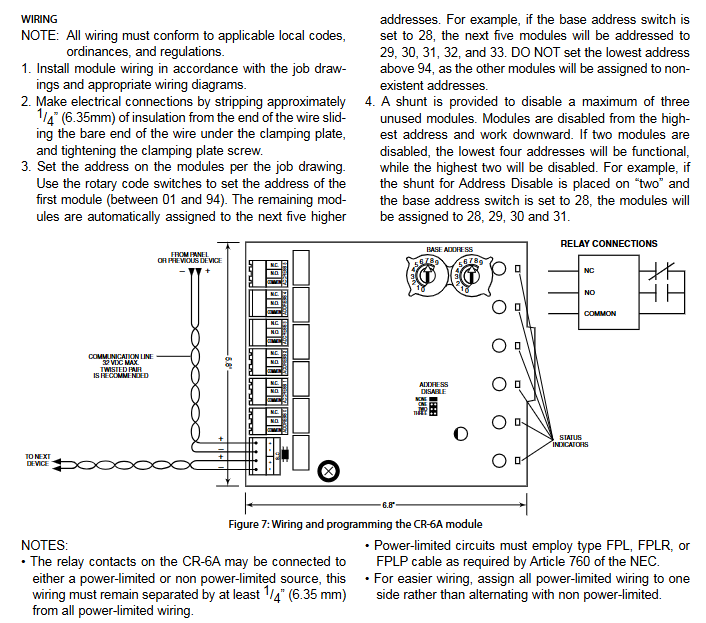

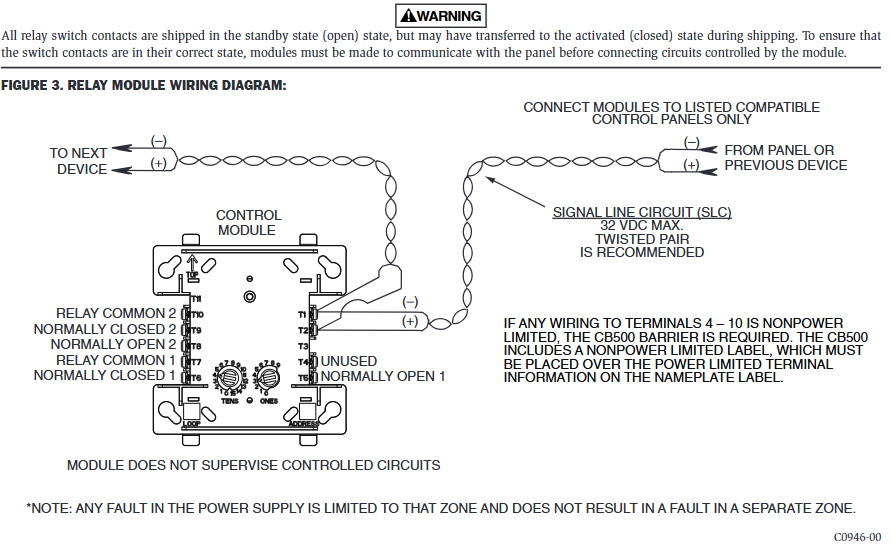

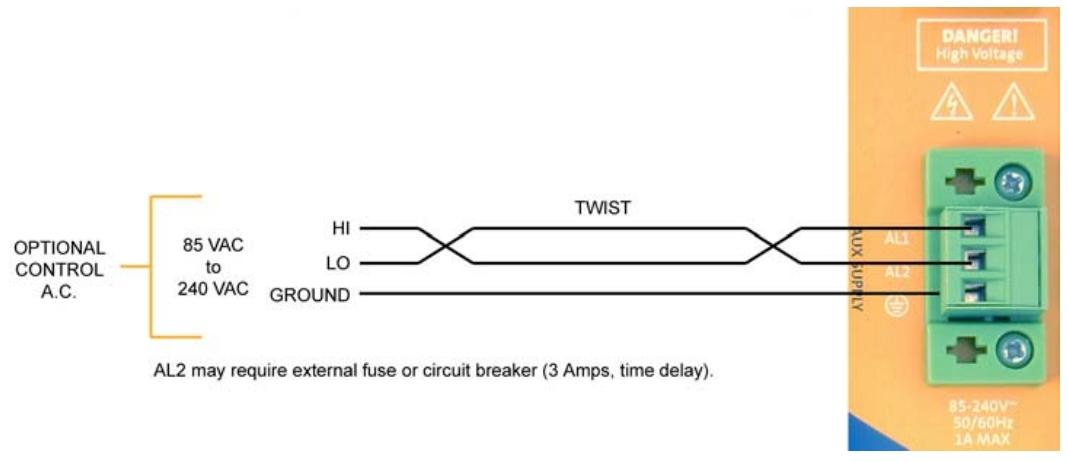

Wiring requirements

All wiring must comply with applicable local codes, regulations, and laws.

Install module wiring according to the engineering drawings and corresponding wiring diagrams.

When making electrical connections, strip approximately 0.25 inches (6.35mm) of insulation from the end of the wire, slide the exposed end of the wire under the clamp, and then tighten the clamp screws.

Set the address on the module according to the engineering drawing, use the rotary encoding switch to set the address of the first module (between 01 and 94), and the remaining modules will be automatically assigned to the next five higher addresses. For example, if the base address switch is set to 28, the next five modules will be addressed as 29, 30, 31, 32, and 33. The minimum address cannot be set to 94 or above, otherwise other modules will be assigned to non-existent addresses.

Provide a splitter to disable up to three unused modules. The module is disabled starting from the highest address and moving downwards. For example, if the shunt with “address disabled” is placed on “2” and the base address switch is set to 28, the module will be assigned to 28, 29, 30, and 31.

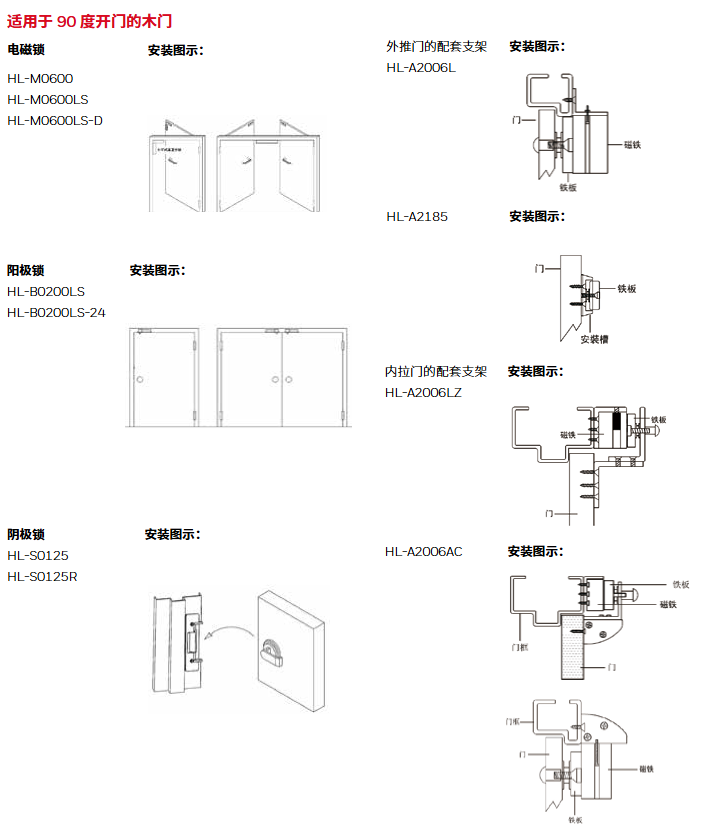

Precautions for Relay Connection

The relay contacts on CR-6A can be connected to power limited or non power limited power sources, but the wiring must be kept at least 0.25 inches (6.35mm) away from all power limited wiring.

The power limiting circuit must use FPL, FPLR, or FPLP type cables as required by NEC Article 760.

For ease of wiring, allocate all power limiting wiring to one side instead of alternating with non power limiting wiring.