ABB Freelance 800F Compact Control System

Product overview

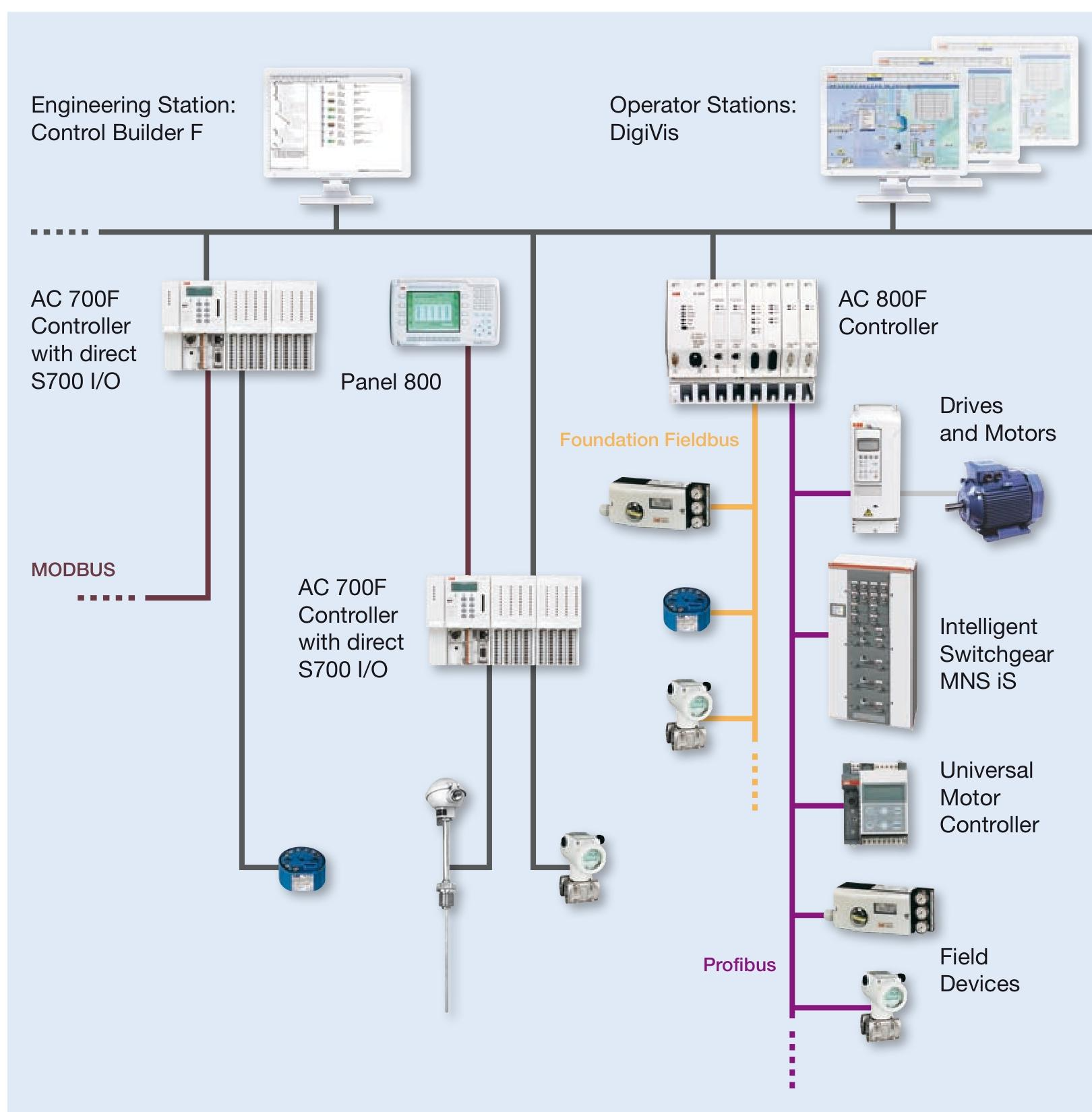

Freelance 800F is a compact and scalable control system launched by ABB, integrating traditional process control technology with enterprise management functions. Its design goal is to achieve high automation at low cost, and it has over 10000 application cases worldwide, covering various industrial fields, especially suitable for scenarios such as power, process or environmental technology factories. This system combines cost-effectiveness of hardware and software, and is easy to use, meeting the diverse needs of projects from small to medium-sized.

Core controller

AC 700F controller

Features: It is a miniaturized process station that can be directly connected to S700 I/O modules, with a compact size.

Applicable scenarios: Suitable for small applications with 16 to 256 I/O points, expanding the application range of Freelance 800F.

Function: It has excellent functionality and usability, supports system expansion, has the same powerful engineering options and convenient visualization capabilities as AC 800F, consistent engineering tools, including DigiVis operating interface, pre configured visualization components, etc., which can be used directly and reduce manual configuration time.

AC 800F controller

Features: As a process station, it can handle process and diagnostic data from up to four fieldbus gateways, with a compact and robust design.

Applicable scenarios: It is suitable for installation in control rooms and can also be used for on-site junction boxes, capable of handling multiple types of fieldbus.

Engineering and Configuration

Engineering Tools: Control Builder F is used as the only engineering tool that supports consistent configuration, debugging, and diagnostics from graphics to field devices, providing all five programming languages specified in IEC 61131-3.

Equipment integration: By using FDT/DTM technology to integrate on-site equipment, there is no need for tedious GSD file integration. The graphical parameter setting dialog boxes (DTMs) provided by equipment manufacturers can transmit specific signals and parameters to control system engineering tools, while completing the main equipment configuration. Most important on-site equipment has corresponding DTMs.

On site layer and communication

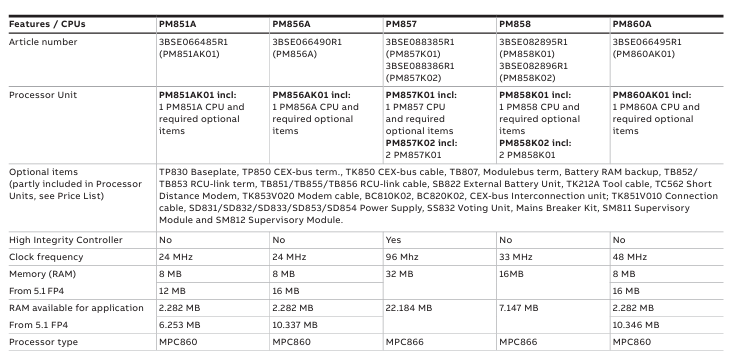

On site equipment connection: ABB provides a wide range of on-site equipment that can be easily integrated into the process layer through mature communication standards. With the help of Profibus, remote I/O can be achieved by connecting to the AC 800F controller. The S800 and S900 I/O systems can connect a large number of sensors and actuators.

Fieldbus support: Supports multiple important fieldbuses, including PROFIBUS-DPV1/PA, FOUNDATION Fieldbus HSE/H1, HART (via remote I/O), MODBUS master-slave mode, CAN for Freelance Rack I/O, and remote protocol IEC870-5-101. A single AC 800F controller can run multiple fieldbuses in parallel.

Operational layer and scalability

Operation interface selection

DigiVis: Moderately priced to meet the standard requirements of process operation and monitoring, supporting dual screen operation, free graphic display, structured operation panel, trend display, hardware diagnostic system display, alarm page, etc. The configuration is fully integrated into Control Builder F, and optional batch packages based on 800xA Batch Management can also be integrated. When using PGIM 800F, advanced information management functions can be obtained.

800xA Operations: Provides more advanced operational functions, supports four screen operation, client server architecture (up to 40 workstations), can integrate multiple Freelance island groups into one interface, and can also integrate batch management and 800xA information management functions. It also supports other interfaces such as Power Generation Portal, SCADAvantageTM, Conductor NT.

Technical transition flexibility: Users can freely choose the transition time from traditional 20mA instruments to digital fieldbus technology, and can run traditional I/O modules and fieldbus devices in parallel, gradually replacing old devices.

System advantages

High availability: After years of industrial application verification, it can meet strict availability requirements, and hardware redundancy can be achieved at all levels, including fieldbus device gateways, networks, controllers, control layers, and bus systems.

Scalability: It can be adapted from small 8-point systems to large systems with over 10000 points, and can be expanded at any time to meet requirements.

Multi functional communication: supports OPC, Ethernet TCP/IP、PROFIBUS、FOUNDATION Fieldbus、MODBUS、HART It also has the functions of alarm voice output, video integration and Internet connection.

Compliance: To meet the requirements of regulatory agencies such as FDA and EFSA, features such as encrypted logs and trend data, audit tracking functionality, access permissions, and user management (security locks) are provided to facilitate the verification process.

Lifecycle management: Through the Automation Sentinel program, control software updates can be maintained, the latest system software versions can be obtained in a timely manner, improving productivity, reducing support costs, and simplifying software management. Upgrading from traditional control systems to Freelance 800F can improve usability and reduce maintenance costs.

Asset management: The control system and related databases provide necessary information on equipment availability and wear and tear, supporting modern asset management methods. Through asset optimization, process analysis is conducted to achieve efficient maintenance and optimization, and to improve capacity utilization.