ABB INSUMMCU2 MCU2A02V24 motor control unit

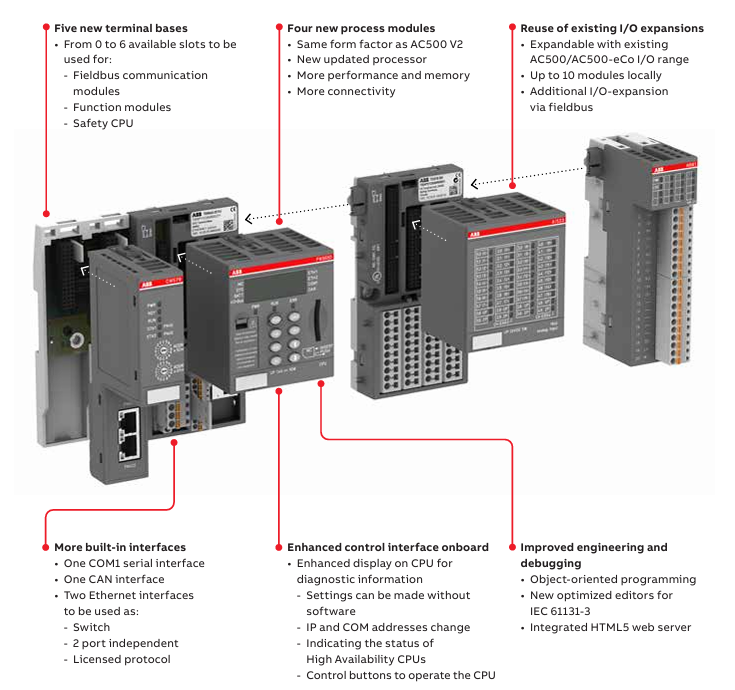

Product overview

Product positioning: MCU is an electronic motor control and protection device with fieldbus interface, mainly used for the protection, control, and monitoring of three-phase/single-phase AC motors and starting equipment. It is divided into MCU1 (basic type) and MCU2 (high-end type).

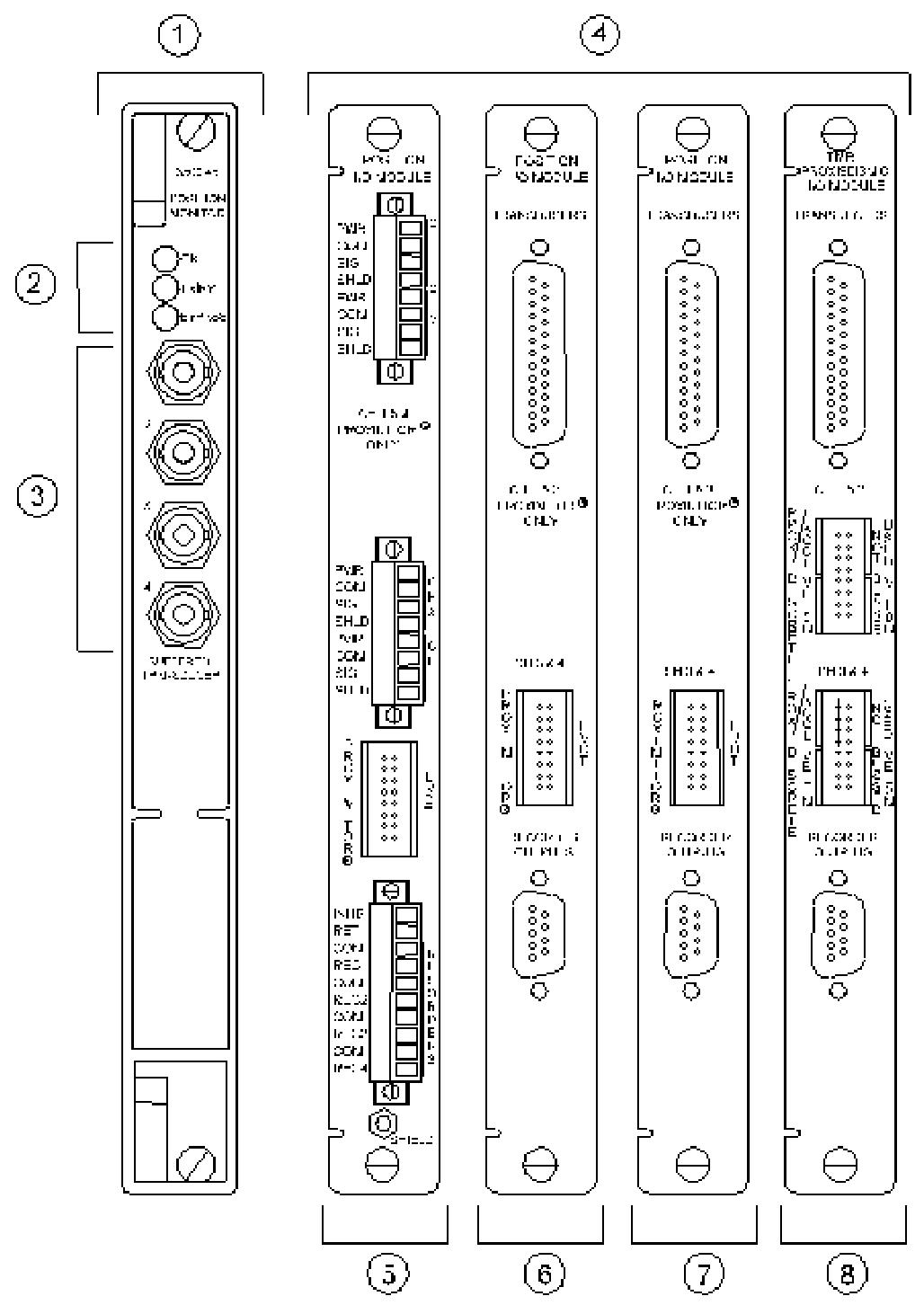

Mechanical structure: It consists of a base plate, a main unit, a current measurement unit, and a voltage unit (optional only for MCU2). The outer shell is made of polycarbonate containing 10% glass fiber, with a fire rating of UL 94 V-0, halogen-free, and a color of RAL 7012.

Model specifications: MCU2 has two current ranges of 0.1-3.2A and 2.0-63A, supporting 380-690VAC voltage and 24VDC/230VAC auxiliary power supply.

Interface function

Power interface: Supports 24VDC (MCU1 and MCU2) and 230VAC (MCU2 only) auxiliary power supplies, with power consumption of 4.7W and 8.2W (maximum), respectively.

Digital input: MCU1 has 12 channels, MCU2 has 17 channels, with a type of 10mA/24VDC, and can be configured as normally open or normally closed.

LED output: 9 channels, used to indicate motor operation status, alarms, and trips, requiring external current limiting resistors.

Contactor control output: MCU1 has 2 channels and MCU2 has 3 channels, equipped with a watchdog relay to prevent abnormal operation of the contactor in case of microprocessor failure.

Communication interface: LonTalk is used ® Protocol, FTT-10A transceiver, supporting LONWorks fieldbus, can achieve parameter configuration and status monitoring through network variables.

Function characteristics

Starter type: Supports multiple starter types, including NR-DOL (unidirectional direct start), REV-DOL (bidirectional direct start), NR-S/D (star delta start), REV-2N (dual speed non reverse), etc. Each type corresponds to different contactor control logic and parameter settings.

Protection function:

Thermal Overload Protection (TOL): Simulate motor thermal capacity, calculate thermal accumulation based on current, and support both standard and EEx e models.

Phase loss protection: detects phase current imbalance to prevent motor phase loss operation.

Underload/no-load protection: detects motor load abnormalities based on current and power factor.

Locked rotor protection: monitors the overcurrent status during motor start-up or operation.

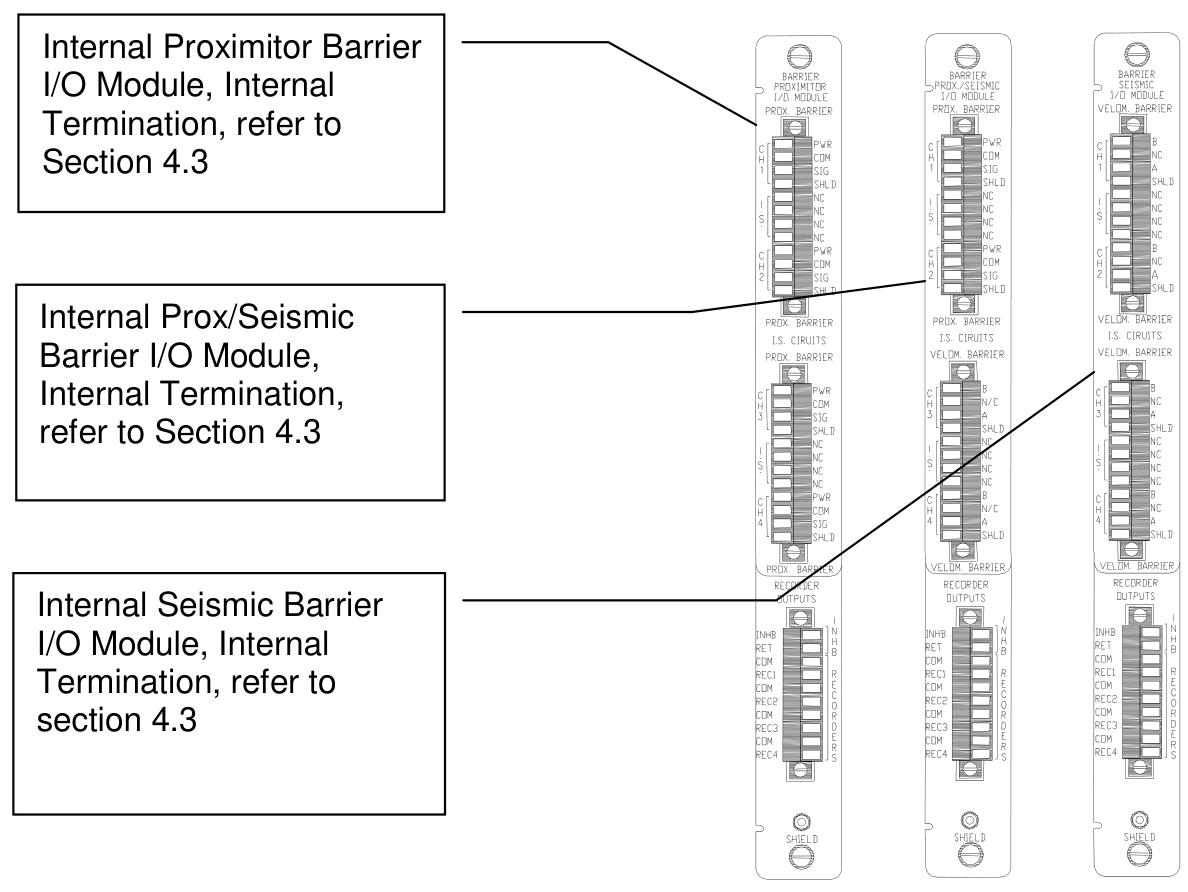

Ground fault protection: Detecting ground faults through residual current transformers or phase current vector sum.

Monitoring and Diagnosis:

Contactor watchdog: monitors the status of the contactor and cuts off the control voltage in case of abnormalities.

Feedback supervision: Verify the consistency between the contactor action and the control command.

Running time counting: records the number of motor running hours and the number of contactor actions, used for maintenance reminders.

Fault record: stores alarm and event information, with timestamps, supports network queries.

Communications and Networking

Protocol and Interface: Using LONWorks fieldbus, supporting SNVT (Standard Network Variable Type), it can communicate with other devices in the INSUM system (such as MMI, gateway).

Network configuration: Supports service/flashing installation mode, achieves device recognition and network connection establishment through testing location input.

Time synchronization: Receive system clock synchronization messages to ensure the accuracy of event timestamps.

Parameter setting and maintenance

Parameterization process: To download parameters through INSUM Operator Station or MMI, the MCU needs to be set to offline mode and support partial or complete parameter file transfer.

Fault code: Display a fault code when parameter settings are incorrect, indicating specific parameter issues (such as out of range, invalid values, etc.).

Technical data: Operating temperature -5 ℃ to+55 ℃, storage temperature -25 ℃ to+85 ℃, protection level IP20, compliant with IEC 60947 and other standards, passed EMC compatibility testing.

ABB INSUM ® Advantages of MCU

Strong communication and integration capabilities: Supports LONWorks fieldbus, can communicate with multiple devices, and achieve system integration. If combined with other ABB devices such as MMI and gateway, it can build an efficient motor management network in complex industrial environments. In the automated production lines of large factories, seamless integration with the upper control system enables centralized monitoring and management of a large number of motors, which is difficult for many other brands to achieve. In contrast, some other brands of motor control units support fewer types of communication protocols, making it difficult to integrate with devices from different manufacturers, which limits the scalability and compatibility of the system.

Comprehensive and precise protection functions: equipped with multiple protection functions such as thermal overload, phase loss, underload/no-load, locked rotor, grounding fault, etc. Its thermal overload protection simulates the motor’s thermal capacity and can accurately monitor the motor’s operating status, effectively avoiding damage to the motor due to abnormal working conditions. Taking the manufacturing industry as an example, in the application scenario of frequent starting and stopping of motors, timely response and protection of motors can be achieved, reducing equipment failure rates and ensuring production continuity. The protection functions of some other brands may not be complete enough, or there may be a lack of protection accuracy, which cannot be compared to ABB INSUM ® MCU provides comprehensive and precise protection for motors.

High product stability: The hardware design adopts a polycarbonate shell containing 10% glass fiber, with a fire rating of UL 94 V-0, halogen-free, and good mechanical stability and electrical insulation performance. The working temperature range is -5 ℃ to+55 ℃, which can adapt to various industrial environments. In some high temperature, high humidity, or corrosive industrial environments, ABB INSUM ® MCU can operate stably, while some other brands of motor control units may not be able to adapt to such harsh environments, resulting in decreased stability and affecting the normal operation of the motor.

Rich product selection: ABB offers different models such as MCU1 and MCU2, suitable for different motor powers and application scenarios. MCU2 has two current ranges to choose from, 0.1-3.2A and 2.0-63A, to meet diverse motor control needs. In contrast, some other brands’ product lines may not be rich enough to meet the specific needs of different users.