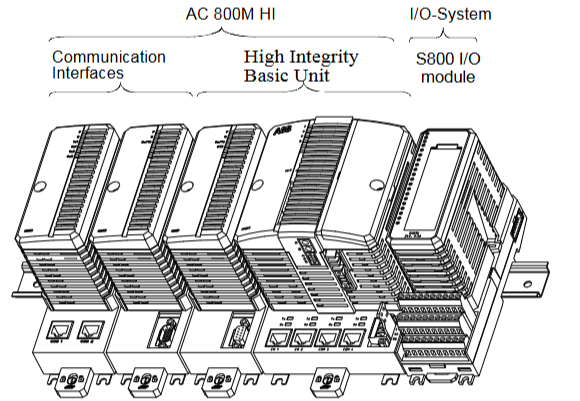

ABB AC 800M 6.0 Controller Hardware

Product overview

Positioning: AC 800M 6.0 is a high-performance modular controller hardware platform that can achieve various process and industrial automation control functions through programming. It is suitable for various industrial scenarios and can serve as an independent controller or undertake local control tasks in the control network.

Core composition: It consists of hardware components such as processor unit, communication interface, power supply unit, battery backup unit, etc. Some high integrity systems also require special modules such as SM810/SM811/SM812.

Hardware components and functions

Processor Unit

Category: Including PM851/PM851A、PM856/PM856A、PM858、PM860/PM860A、PM861/PM861A、PM862、PM864/PM864A、PM865、PM866/PM866A、PM867、PM891 There are differences in performance and configuration among different models, such as PM891 using MPC8270 microprocessor with a running speed of 450MHz, which is about three times the performance of PM864.

Function: Includes microprocessor, RAM memory, real-time clock, LED indicator lights, initialization button, etc., responsible for running firmware and application programs, and controlling the operation of the entire system. Support redundant configuration, with a primary backup switching time of less than 10ms, and the process output remains frozen during switching.

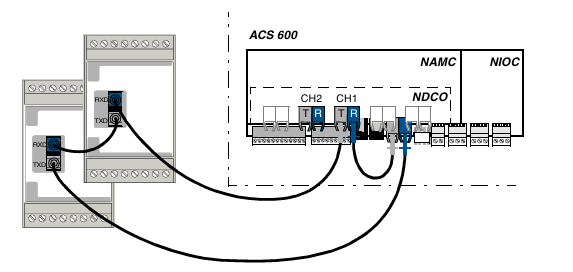

Communication interface

Diverse types: including RS-232C(CI853)、PROFIBUS DP(CI854/CI854A/CI854B)、MasterBus 300(CI855)、S100 I/O(CI856)、INSUM(CI857)、DriveBus(CI858)、FOUNDATION Fieldbus HSE(CI860) Multiple interfaces are available to expand the communication capabilities of the processor unit, supporting different protocols and device connections.

Function: Implement communication between the controller and external devices, networks, such as connecting remote I/O, fieldbus instruments, drivers, etc.

Power and battery backup

Power supply units, such as SD831, SD832, SD833, SD834, etc., are switch mode power converters that convert AC or DC inputs into stable 24V DC outputs. They support redundant configurations and need to be used in conjunction with voting units (such as SS823, SS832).

Battery backup: includes internal batteries (some models) and external batteries (SB821, SB822), used to provide backup power for memory and real-time clock in case of power failure. SB822 is a rechargeable lithium battery, while PM891 only supports external battery backup.

Other Components

CEX Bus interconnect units, such as BC810 and BC820, are used to divide CEX Bus into independent segments, improve system availability, and support redundant communication interfaces.

SM modules: SM810, SM811, SM812 are used for intelligent monitoring of high integrity controllers. SM811 and PM865, SM812 and PM867 can form a 1oo2 structure, supporting SIL3 applications respectively.

Technical Parameter

Processor performance: Different models of processors have different microprocessor models, operating frequencies, memory capacities, etc. For example, PM864/PM865 uses the 96MHz MPC862 microprocessor, while PM891 uses the 450MHz MPC8270 microprocessor.

Communication capability: Supports multiple communication protocols and rates, such as PROFIBUS DP supporting 9.6kbit/s-12000kbit/s, Ethernet ports supporting 10/100Mbit/s, etc.

Power parameters: The input voltage range, output voltage, and rated current of the power supply vary. For example, the SD831 has an input of 100-240V AC or 110-300V DC and an output of 24V DC/3A.

Environmental parameters: working temperature, storage temperature, humidity, etc. The working temperature range is usually -25 ° C to+60 ° C (some models may vary), and the relative humidity is 5% -85% without condensation