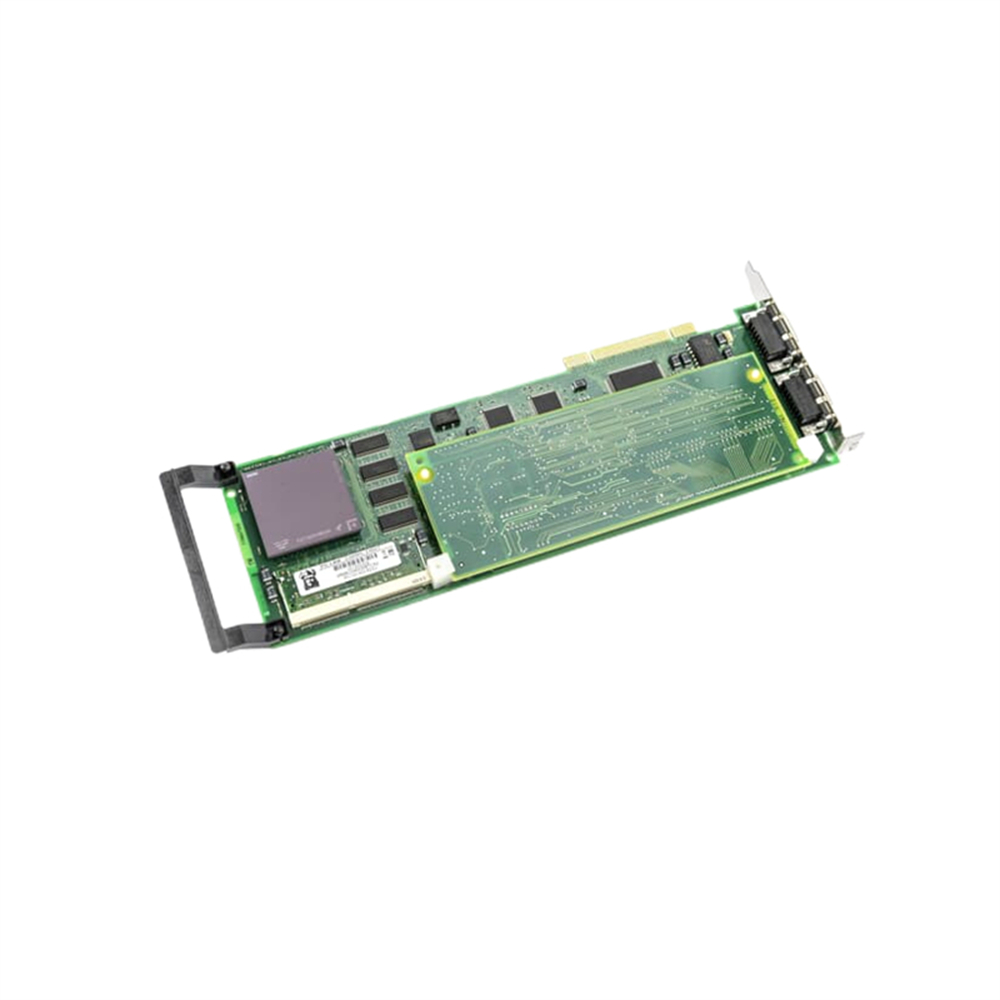

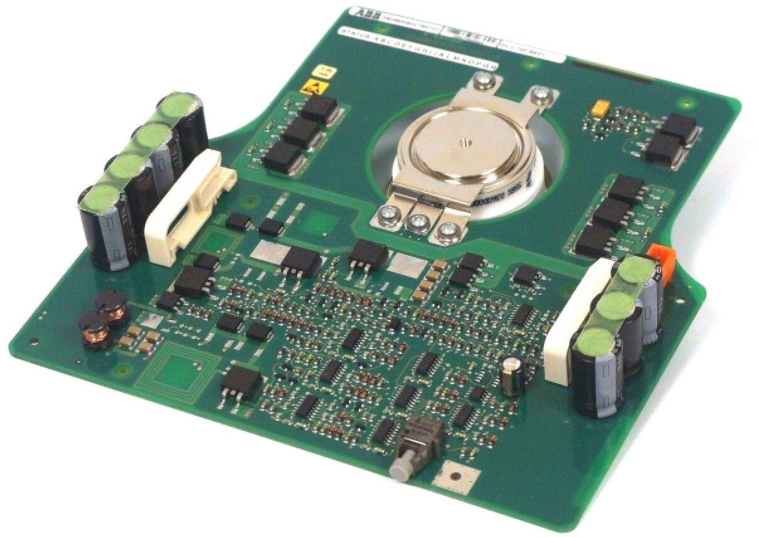

ABB DTDX991A 61430001-UW servo controller

Product Overview

ABB DTDX991A 61430001-UW is a high-performance servo controller specially designed for industrial automation. With excellent signal processing capabilities and precise control performance, it can ensure stable and efficient system operation in many complex industrial scenarios such as manufacturing, process control, and energy management. Its reliable quality and outstanding performance have become key components highly favored in the field of industrial automation.

Core parameters

Input/output characteristics: The input voltage of this controller is 24V DC, and the output voltage can be flexibly adjusted, usually up to 24V DC. The rated current of each channel is 1A, with a maximum of 16 channels and a maximum total output current of 2A. This configuration enables it to adapt to various load requirements, whether driving small precision equipment or providing power control for large industrial machinery, it can be accurately matched to ensure stable operation of the equipment.

Physical specifications: The product has a compact appearance with dimensions of 100mm x 100mm x 25mm (width x height x depth) and weighs only 0.5kg. The compact and lightweight design not only facilitates installation in control cabinets with limited space, but also does not impose too much burden on the overall structure of the equipment, greatly improving its applicability in various industrial environments.

Electrical performance: The input voltage range is DC 5V to 30V, demonstrating good voltage adaptability and compatibility with different power environments. The working temperature range is very wide, from -40 ° C to+85 ° C, which can work stably under extreme environmental conditions such as high and low temperatures, ensuring that industrial automation systems can continue to operate under various complex working conditions without excessive interference from environmental temperature changes.

Certification status: Obtained multiple international authoritative certifications such as CE, UL, ATEX, etc. These certifications not only highly recognize product quality and safety, but also mean that the servo controller meets a wide range of global industry standards and can be used with confidence in various industrial projects in different countries and regions, providing strong guarantees for multinational enterprises and global industrial projects.

Core advantages

Accurate signal processing: By utilizing advanced digital signal processing technology, various input signals can be quickly and accurately processed to achieve precise perception and feedback of equipment operating status. In industrial automation production lines, small changes in equipment operation can be accurately captured, control strategies can be adjusted in a timely manner, ensuring high precision and consistency in product production, effectively reducing defect rates, and improving production quality.

High reliability: From component selection to overall structural design, it has undergone strict control and optimization, possessing excellent anti-interference ability and stability. In the complex electromagnetic environment of industrial sites, it can effectively resist electromagnetic interference, ensure accurate transmission and execution of control signals, reduce equipment failures caused by signal interference, and provide solid support for the long-term stable operation of industrial automation systems.

Convenient integration: The design fully considers compatibility with existing industrial systems and can be seamlessly integrated into ABB’s PLC systems and other common automation control systems. Without the need for large-scale modifications to the existing system, it can be quickly integrated, greatly reducing the cost and difficulty of system upgrades and transformations, and improving the implementation efficiency of industrial automation projects.

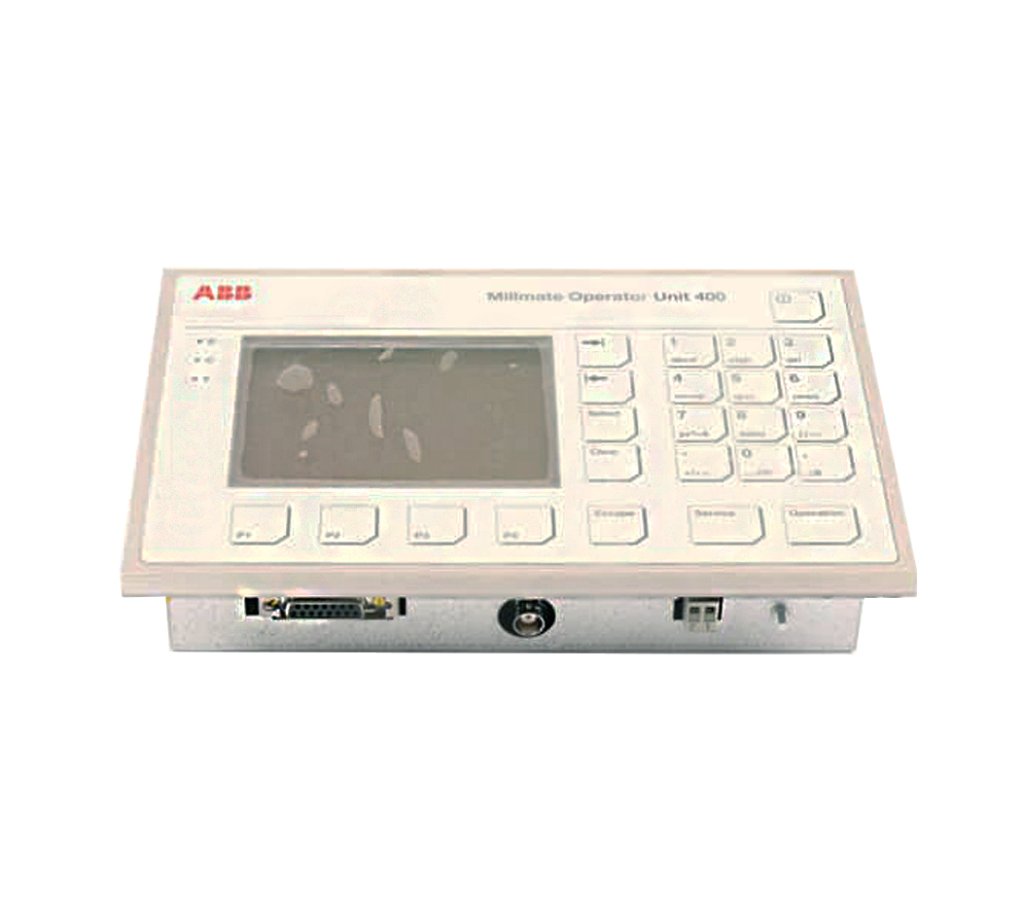

Easy to maintain: Adopting a user-friendly interface design makes installation, debugging, and daily maintenance work simple and convenient. Operators can quickly complete parameter configuration and troubleshooting through an intuitive interface, effectively reducing equipment downtime and improving production efficiency. Meanwhile, its compact structure and modular design also facilitate the replacement of individual modules when needed, further reducing maintenance costs.

Application Fields

Manufacturing industry: In industries such as automobile manufacturing and electronics manufacturing, it is used to control robot arms, precision machining equipment, etc. in automated production lines. For example, on an automotive assembly line, the movements of robot arms can be precisely controlled to achieve precise grasping and installation of components; In the process of electronic chip manufacturing, it is possible to accurately control the movement of equipment such as lithography machines to ensure the high precision requirements of chip manufacturing.

Process control industry: widely used in production process control in chemical, petroleum, pharmaceutical and other fields. In the temperature and pressure control of chemical reaction vessels, precise control of reaction conditions can be achieved by adjusting the speed and operating status of servo motors, ensuring the smooth progress of chemical reactions and stable product quality; In the pharmaceutical industry’s drug filling production line, the action of the filling equipment can be precisely controlled to ensure the accuracy of the drug filling volume.

In the field of energy management, it can be used for controlling new energy equipment such as wind power generation and solar power generation. In wind power generation systems, by adjusting the servo controller, the angle and speed of the wind turbine blades are precisely adjusted according to changes in wind speed, achieving efficient capture and conversion of wind energy; In the solar photovoltaic power generation system, the tracking device that can control the photovoltaic panel can always aim at the sun, improving the efficiency of photovoltaic power generation.