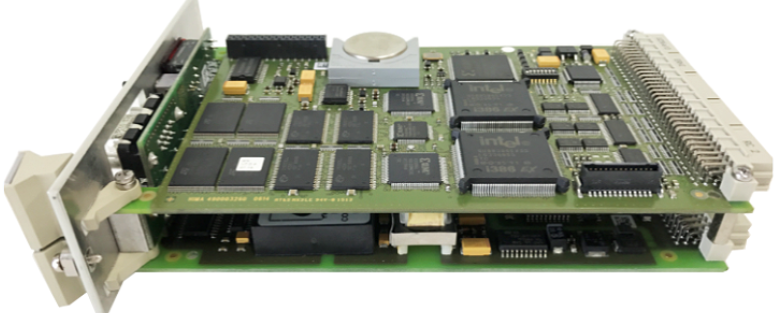

ABB 3BHB003154R0101 5SXE05-0156 IGCT module

Performance parameters

Power processing capability: This IGCT module can handle up to 100kW of power, meeting the operational requirements of numerous industrial equipment and systems with high power demand, and providing stable and strong power support for various complex industrial scenarios.

Working voltage range: Its working voltage range is between 600V AC and 1200V AC, which enables it to adapt to diverse medium voltage power standards in different regions and industrial environments, and has wide applicability. It can operate reliably in both general industrial production workshops and precision manufacturing fields that require high voltage stability.

Switching frequency: The maximum switching frequency can reach 10kHz, enabling the module to quickly and accurately control current and voltage, ensuring efficient operation of the power system. In application scenarios that require frequent power switching and adjustment, the ability to quickly respond to control instructions ensures the dynamic performance of the system.

Insulation level: It has an insulation level of H (180 ° C), which means it can maintain good insulation performance in high temperature environments, effectively preventing electrical short circuits and other faults, and improving the reliability and safety of the module in complex working environments. Even in some industrial places with poor heat dissipation conditions or high ambient temperatures, it can still work stably.

Cooling method: Adopting air-cooled cooling method, this cooling method has a relatively simple structure and does not require a complex water-cooled circulation system, reducing equipment maintenance costs and system complexity. At the same time, the air cooling method can to some extent meet the heat dissipation needs of the module during normal operation, ensuring that the module operates within a suitable temperature range, thereby extending its service life.

Product Features

Excellent electrical performance: IGCT modules have strong electrical performance advantages. On the one hand, it can withstand high voltage and high current, maintain stable operation under high voltage and high current working conditions, and is not prone to device damage and other problems. On the other hand, it has a long service life, thanks to advanced semiconductor materials and manufacturing processes, which slow down the performance degradation of modules during long-term, high-intensity operation, greatly reducing the frequency of equipment replacement, lowering maintenance costs, and improving the continuity and stability of industrial production.

Advanced design concept: Utilizing IGCT technology, advanced materials and processes are employed in the design. The casing is usually made of sturdy aluminum material, which not only has good mechanical strength and can effectively protect the internal precision semiconductor components from external mechanical impacts, but also has certain heat dissipation performance, helping to improve the overall heat dissipation efficiency of the module. The internal semiconductor components have been carefully selected and optimized to ensure efficient and stable operation of the module under various working conditions, achieving a perfect combination of high performance and high reliability.

Wide environmental adaptability: With a wide working temperature range, it can adapt to various extreme temperature environments from cold Arctic regions to hot desert areas. At the same time, its high insulation resistance characteristics enable the module to maintain good electrical performance even in harsh environmental conditions such as humidity and dust, without causing electrical failures due to insulation performance degradation caused by environmental factors. This excellent environmental adaptability enables the IGCT module to be widely applied in various complex industrial environments worldwide.

Product specifications

Size: The module size is 165mm x 100mm, which is designed to be compact and reasonable, making it easy to install and integrate in the limited space of various industrial equipment. It can effectively save equipment space and improve the flexibility of equipment layout. Both small industrial control cabinets and large power equipment cabinets can conveniently accommodate this module.

Weight: The weight is about 0.3kg. The relatively light weight not only facilitates the installation and handling of the module, reduces the labor intensity during the installation process, but also helps to reduce the overall load of the equipment. It is of great significance for some application scenarios that have strict requirements for equipment weight, such as some special power equipment in the aerospace industry.

Certification: This product has passed internationally renowned certifications such as CE and UL. CE certification indicates compliance with European safety, health, and environmental standards, while UL certification reflects recognition of its safety and reliability in the US market. These certifications are a strong endorsement of product quality and performance, providing users with confidence in using the product globally, ensuring that the product complies with local regulations and standards in different countries and regions.

Application Fields

Industrial automation: In industrial automation production lines, this IGCT module is commonly used for motor control. For example, in the conveyor belt system of a large automated factory, precise control of the motor can achieve stable and efficient operation of the conveyor belt, ensuring fast and accurate transmission of products on the production line. In terms of motion control of automated mechanical equipment, it can accurately adjust parameters such as motor speed and torque according to production process requirements, ensuring the accuracy and stability of equipment motion, thereby improving product processing quality and production efficiency.

Power system: IGCT modules play an important role in high-voltage transmission and distribution in the power system. For example, in high-voltage direct current transmission (HVDC) systems, it is used to achieve AC-DC conversion, which can efficiently control the direction and power size of power transmission, and improve the stability and reliability of the transmission system. In medium voltage distribution networks, it can be used for equipment such as Static Var Compensators (SVC) to quickly and accurately compensate for the reactive power of the power grid, improve the power quality of the grid, reduce line losses, and ensure the safe and stable operation of the power system.

New energy generation: This module is also widely used in new energy fields such as wind power generation and solar photovoltaic power generation. In the wind power generation system, the inverter used for wind turbines is used to convert and control the output electrical energy of the generator, ensuring that the wind turbine can stably convert wind energy into electrical energy and connect it to the grid. In solar photovoltaic power generation systems, it can be used as a photovoltaic inverter to convert the direct current generated by photovoltaic panels into alternating current, achieving efficient matching with the power grid and stable output of electrical energy, improving the overall efficiency and reliability of new energy generation systems.