Honeywell HC900 Process and Safety Controller

Product positioning and core features

HC900 is a modular process and safety controller launched by Honeywell, suitable for small and medium-sized industrial control scenarios, supporting process control and safety logic integration. Its core features include:

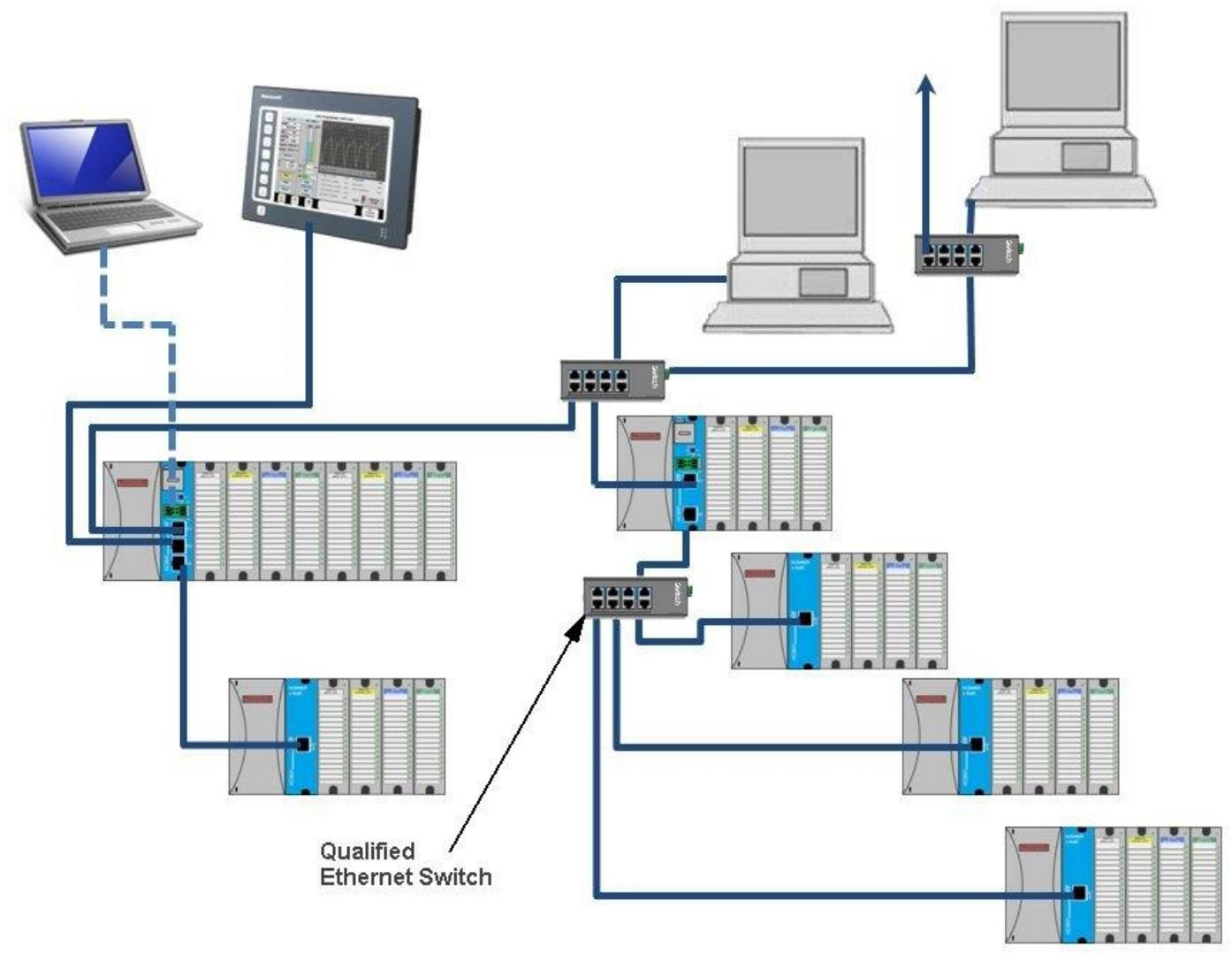

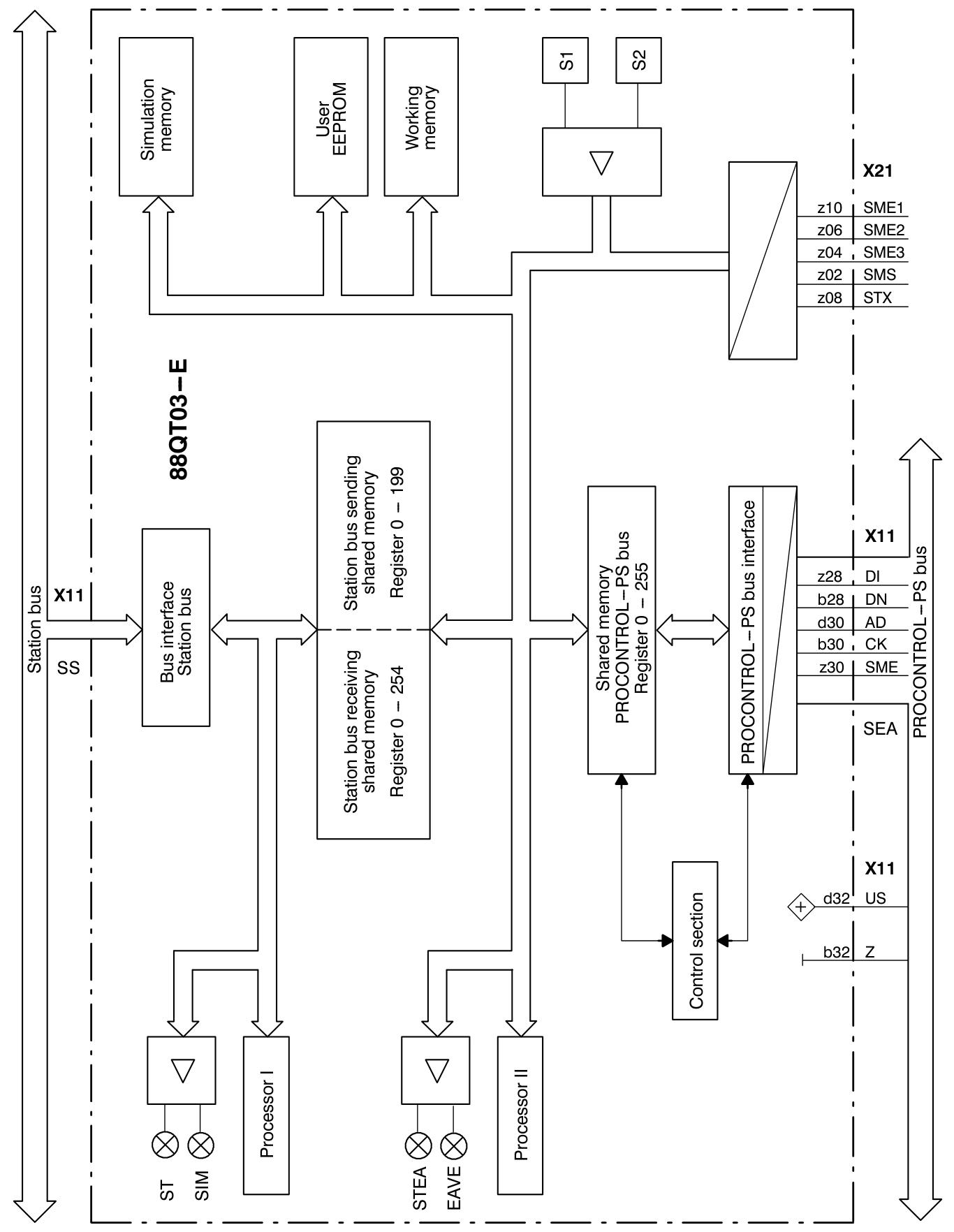

Modular architecture: Supports rack mounted installation, expandable I/O modules (4/8/12 slot rack), compatible with redundant configurations (C75 CPU supports dual CPU hot standby).

High performance control: Integrated PID control, self-tuning algorithm, gain scheduling and other functions, supporting up to 5000 functional blocks to meet complex control strategy requirements.

Multi protocol communication: Built in Ethernet (Modbus/TCP, Peer to Peer), RS-485 (Modbus RTU), supporting seamless integration with SCADA and HMI systems.

Safety certification: Compliant with SIL standards, supports safety function blocks, suitable for safety critical applications (such as ATEX certification, suitable for explosion-proof environments).

Hardware Components and Architecture

Core components

Controller module: C30/C50/C70/C75 models, supporting local I/O or remote expansion, C75 supports redundant configuration.

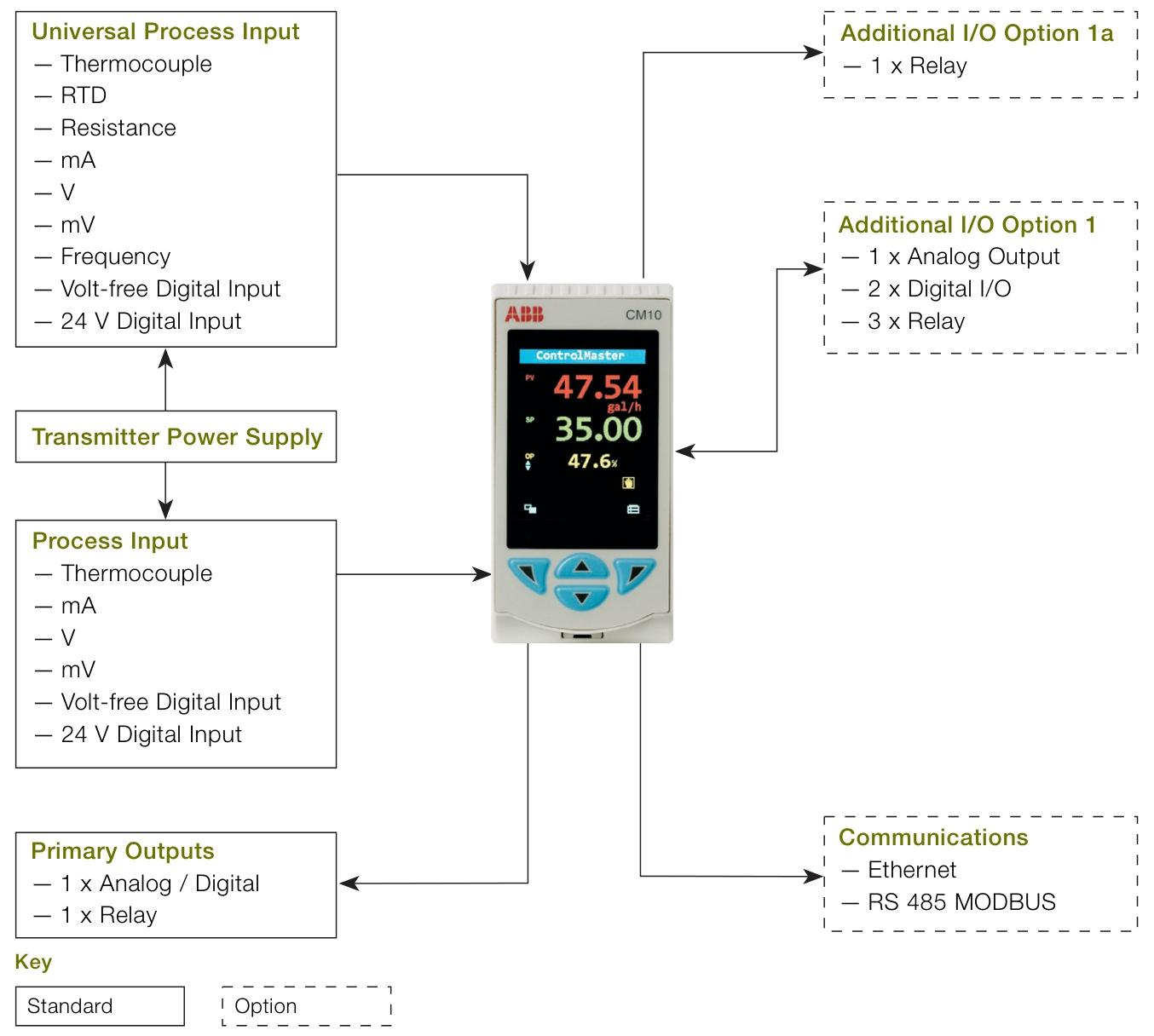

I/O module: including analog input/output (AI/AO), digital input/output (DI/DO), relay output, pulse/frequency module, etc., supporting hot swapping (RIPP).

Power module: AC 120/240V or DC 24V power supply, supports redundant power configuration, built-in overcurrent protection.

Scanning module: S50/S75 model, connected to controller and I/O rack, supports fiber optic extension for long-distance communication.

Redundant architecture

Dual CPU redundancy: C75 CPU supports primary and backup switching, automatic failover in case of failure, and switching time<4 control cycles.

Power and network redundancy: Supports redundant power supplies and Ethernet links to enhance system reliability.

Function and Control Strategy

control function

PID control: Supports AccuTune III self-tuning and adapts to gain scheduling of nonlinear processes (automatic switching of 3 sets of PID parameters).

Sequential control: Supports 50 step sequencers and 50 segment set point programmers, suitable for batch control and temperature curve control.

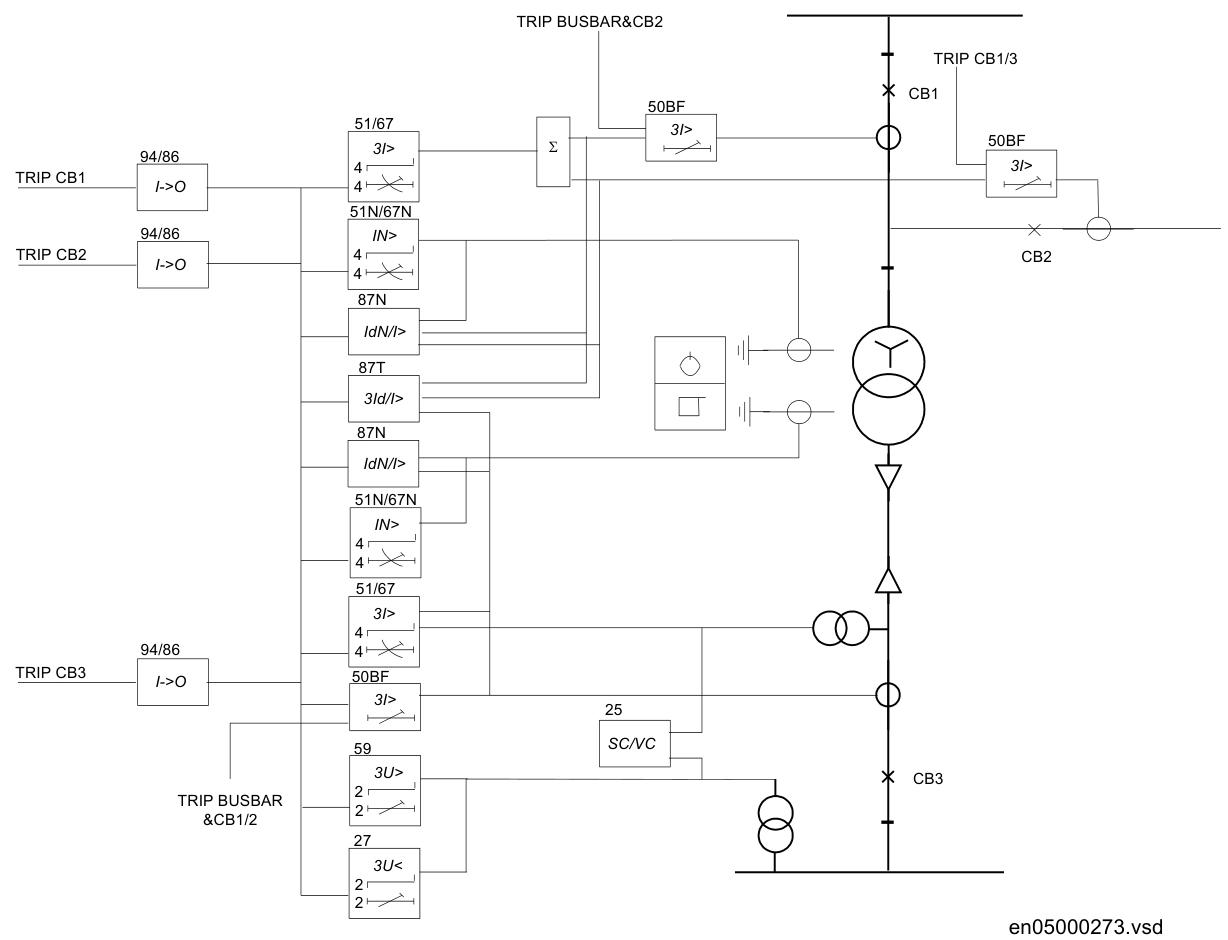

Safety function: Built in safety logic block, supports emergency stop (E-stop), safety interlock, and complies with SIL certification.

Communication and Integration

Modbus/TCP: Supports 10 concurrent host connections, compatible with OPC servers and HMI (such as Expert HS).

Peer to Peer: Supports data exchange between 32 controllers and achieves fast data synchronization through UDP protocol.

Remote configuration: Download configuration remotely through Designer software or web server, and support firmware upgrade.

Installation and Configuration

hardware install

Rack installation: Supports vertical/horizontal installation, requires reserved heat dissipation space, ambient temperature 0-55 ℃, humidity 5% -95% (non condensing).

Wiring specifications: Analog signals require shielded twisted pair cables, digital signals support 24V DC/120/240V AC, and grounding must comply with EMC standards.

Remote Terminal Panel (RTP): simplifies on-site wiring, supports 8-point AI, relay output modules, and is compatible with DIN rail installation.

software configuration

Designer software: graphical programming interface, supporting drag and drop of functional blocks, parameter tuning, diagnostic monitoring.

Configuration tool: Download configuration through RS-485 or Ethernet, supporting cold start/hot start mode switching.

Diagnosis and maintenance

LED diagnosis: The CPU, scanning module, and I/O module are all equipped with status indicator lights that support flashing fault codes (such as RAM errors, communication interruptions).

Online monitoring: Real time viewing of I/O status and fault logs through HMI or Designer software, supporting historical data recording.

Maintenance process: Supports hot swappable module replacement, battery backup RAM data (30 day battery life), and requires regular calibration of analog modules.