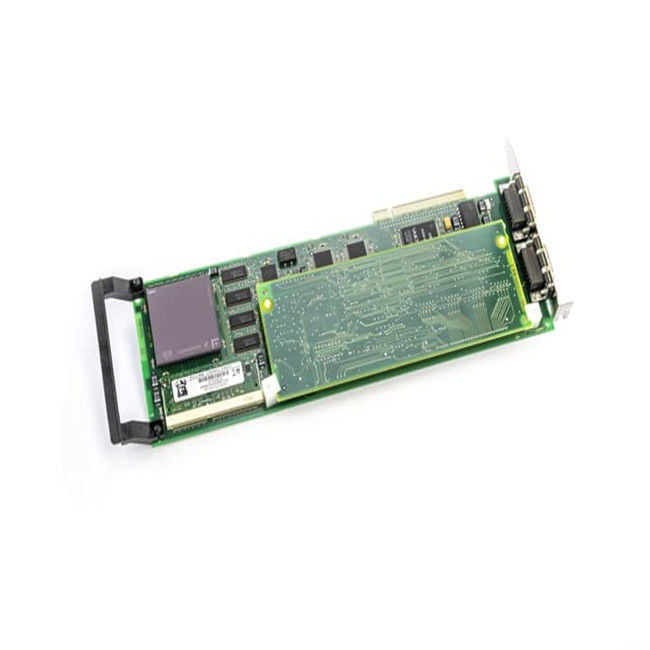

ABB 3BHT300007R1 DO630 Digital Output 16ch 250VAC

Product Overview

ABB 3BHT300007R1 DO630 is a digital output module with 16 channels that can support voltage output up to 250VAC. It is mainly used in industrial automation control system, which can convert the digital signals from the controller into corresponding electrical outputs, and then control all kinds of external devices, such as contactors, solenoid valves, indicator lights, etc., to achieve precise control of the industrial production process and automation management.

Specifications

Number of channels: 16 digital output channels, can control 16 independent devices at the same time, to meet the diverse control needs.

Voltage range: support up to 250VAC AC voltage output, adapt to a variety of industrial power environment.

Output current: each channel has a certain driving capacity, can stably drive the connected load equipment, the specific output current parameters can refer to the product manual.

Isolation: The channels are electrically isolated from each other, effectively preventing signal interference and electrical faults from affecting each other, and enhancing the reliability and safety of the system.

Status Indication: Equipped with LED indicator, it can intuitively display the output status of each channel, which is convenient for the operator to quickly judge the operation of the equipment and find out the faults in time.

Communication interface: supports communication with commonly used controllers in industrial automation system, such as PLC, etc., to achieve rapid data transmission and accurate control.

Working temperature: it can work stably in a certain temperature range, the general working temperature range is – 40℃ – 70℃, adapting to the temperature requirements of different industrial environments.

Performance Advantages

High Reliability and Stability: Adopting high quality electronic components and advanced manufacturing process, after strict testing and quality inspection, to ensure that the module can operate stably for a long time in complex industrial environments, to reduce the probability of failure, and to reduce the maintenance cost.

Flexible Configuration and Expansion: 16 independent output channels can be flexibly configured according to the actual needs, whether it is a single device control or multi-device co-control, can be easily dealt with. At the same time, the module can also be used in conjunction with other ABB automation products, facilitating system expansion and upgrading.

Fast Response and Precise Control: With fast signal response capability, the module can convert controller commands into output signals in a timely manner, achieving precise control of external equipment and improving production efficiency and product quality.

Easy Installation and Maintenance: The module adopts a standardised design and is easy to install, and can be mounted directly on the DIN rail of the control cabinet. Moreover, the clear status indicator and fault diagnosis function make the troubleshooting and maintenance work more efficient.

Attention

Installation environment: It should be installed in a dry, well-ventilated environment without corrosive gases to avoid high temperature, humidity, dust and other harsh environments affecting the performance and service life of the module. The installation location should be far away from strong electromagnetic interference sources to prevent electromagnetic interference resulting in abnormal output signals.

Wiring operation: Be sure to disconnect the power supply before wiring, strictly in accordance with the wiring diagram for correct wiring. Ensure that the wiring is firm, to avoid loose, short-circuit and other problems. Pay attention to differentiate the terminals of different channels to prevent damage to the equipment due to wrong connection.

Load matching: Before use, make sure that the rated voltage, current and other parameters of the connected load match the output capacity of the module, and overloading is strictly prohibited to avoid damage to the module.

System debugging: In the process of system debugging, gradually check the output function of each channel to ensure that the output signal is consistent with the controller instructions. If any abnormality is found, consult the product manual or contact professional technicians to deal with it.

Comparable Models

ABB DO631: ABB DO631 is also a digital output module, but compared with DO630, DO631 may have differences in some performance parameters and functional characteristics. For example, the number of output channels, voltage or current specifications may be different, suitable for industrial automation scenarios with slightly different output requirements.

Similar models of other brands: Other brands in the market have also introduced digital output modules with similar functions, such as Siemens, Schneider and other brands of related products. These products have their own characteristics in terms of performance, interfaces, communication protocols, and so on. Siemens digital output modules may be better in terms of compatibility with Siemens’ own PLC system; Schneider’s products may have a unique advantage in terms of electrical protection functions. In contrast, the ABB 3BHT300007R1 DO630 is more competitive in terms of stability and versatility, thanks to ABB’s strong brand technical support and a wide range of industrial application cases.

Categories

Control System Products → I/O Products → S600 I/O → S600 I/O – Modules → DO630 Digital Outputs → DO630 Digital Output

Control Systems → Advant OCS with Master SW → Controllers → Advant Controller 160 → Advant Controller 160 Version 2.2 → I/O

Modules

Control Systems → Advant OCS with Master SW → I/Os → S600 I/O → I/O Modules