ABB Arc Welding System M2004 IRC5

The ABB arc welding system M2004 IRC5 is a welding solution that combines advanced technology and excellent performance. It occupies an important position in the welding field of modern manufacturing and is widely used in many industries such as automotive manufacturing, mechanical processing, and metal structures. With its efficient, precise, and stable welding performance, it helps enterprises improve production quality and efficiency.

System composition

Robot body: The M2004 robot body has excellent motion performance and flexibility. It has 6 degrees of freedom and can achieve flexible movement in all directions in three-dimensional space, making it easy to reach various welding positions of complex workpieces. The robot body adopts a lightweight design with a compact structure. While ensuring high strength and rigidity, it reduces its own weight, effectively reduces motion inertia, improves motion speed and acceleration, and makes the welding process faster and more efficient. At the same time, its joint parts have been specially designed and optimized to have good sealing and wear resistance, which can adapt to harsh industrial environments and ensure long-term stable operation.

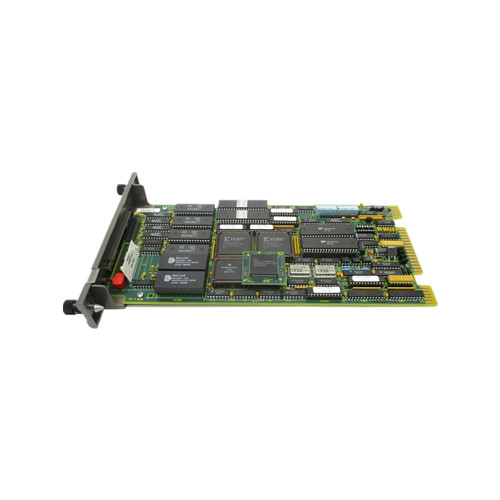

IRC5 controller: The IRC5 controller is the core brain of the entire arc welding system, using advanced multi-core processor technology and possessing powerful computing power and data processing speed. It can accurately control the robot’s motion trajectory, welding parameters, and collaborative work with surrounding equipment in real time. Supports multiple programming methods, including demonstration programming, offline programming, etc., making it convenient for operators to perform programming operations according to actual needs. In addition, the IRC5 controller also has rich communication interfaces, which can quickly and stably exchange data with devices such as PLC, sensors, and welding machines, achieving intelligent integration and collaborative control of the entire welding system.

Welding power supply: The matching welding power supply is specially designed for arc welding process, which can provide stable and reliable welding current and voltage output. It has multiple welding modes, such as MIG (gas metal arc welding), MAG (active gas metal arc welding), TIG (tungsten inert gas welding), etc., which can be flexibly switched according to different welding materials and process requirements. By closely cooperating with the IRC5 controller, the welding power supply can achieve precise control of welding parameters, such as current size, voltage level, wire feeding speed, etc., ensuring consistency and stability of welding quality.

Peripheral equipment: including welding guns, wire feeders, welding fixtures, and other peripheral equipment. The welding gun is made of high-quality materials, with good conductivity and heat dissipation performance, which can effectively extend its service life. The wire feeder can stably and accurately transport the welding wire, ensuring the continuity of the welding process. The welding fixture is used to fix the workpiece, ensure the positional accuracy of the workpiece during the welding process, and improve the welding quality.

An arc welding system which is delivered by ABB Automation Technologies AB is at delivery booted with a configuration that is customized for the delivery. In most cases there is also a set of software drivers for the equipment loaded. There might still be reasons to use this installation description. Obvious examples are:

• A system is to be installed at the customer site.

• The RobotWare software is to be replaced.

• The loaded software must be replaced.

• The configuration is to be changed.

• A stalled system has to be restarted.

• To change the language.

Content of the diskette

The “Arc Welding System Configuration Diskette” contains only options acc. to specification.

For example:

• I/O-board options.

• Addresses and names for all user signals needed for the delivered system.

• Configuration options for positioners in the delivered system.

• Configuration for arc process equipment in the delivered system.

• Configuration options for delivered sensors.

• Default configuration options for welding functions.

• Drivers, where appropriate, for positioner, operators panel and safety

User´s configuration

In cases where there are complementary requirements, it is recommended to use make a new one and, add or change configuration components, and save the lot on a user´s configuration diskette.

Installation procedure

As mentioned in ABB Robotics manuals the pc application System builder in RobotStudioOnline is used to create and download systems to the controller.

When a system is created or updated the external option can be added.

From an external PC

The installation of the robot software is done:

• From an external PC.

• From a diskette (the robot controller need to bee equipped with a diskette drive).

The application handling the booting of the RobotWare is called System builder in

RobotStudioOnline.

There are two ways to establish connection with the robot:

1. The robots are connected to a local network (the LAN output on the robot)making it possible to run System builder in RobotStudioOnline to come into contact with the hard disk of the robots from a PC connected to the same network. This is applicable when there is more than one robot at the same place.

2. From a computer with direct connection to the service output of the robot

network

X-start

A restart must be implemented to be able to load new software.

An X-start will exit the running system, store system data on the mass storage memory, and then execute the BootServer to present the Start window. Any system stored in the mass storage memory, may then be selected.

When X-start is executed, all the saved system data is reset (in a similar way as with a warm start).