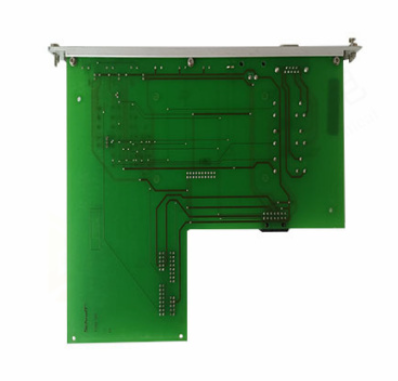

ABB NU8976A High Performance Digital I/O Module

Product Overview

The ABB NU8976A high-performance digital I/O module is a core component developed by ABB, dedicated to data exchange and equipment control in the field of industrial automation. With advanced design and excellent performance, this module can quickly and accurately achieve input acquisition and output control of digital signals, and plays a key role in data transmission and logic execution in industrial control systems. Its compact structural design not only saves installation space, but also facilitates integration into various industrial equipment and automation systems. Through standardized communication protocols and interfaces, NU8976A can seamlessly connect with various controllers, sensors, and actuators, providing reliable support for the automation and intelligent upgrading of industrial production.

Specification parameters

Working voltage: Supports direct current power input within a specific voltage range, such as 24V DC ± 10%. Equipped with an efficient voltage regulator circuit, it can work stably in industrial sites with large voltage fluctuations, ensuring the stability and reliability of module operation.

Communication interface: equipped with Ethernet interface, supporting industrial communication protocols such as Modbus TCP, Profinet, etc., to achieve high-speed and stable data transmission; Equipped with RS-485 interface and supporting Modbus RTU protocol, it facilitates network communication with other devices.

Data transmission rate: The maximum data transmission rate of Ethernet interface can reach 100Mbps, and the data transmission rate of RS-485 interface can reach [X] Kbps, meeting the data transmission needs of different industrial scenarios.

Working temperature: It can operate stably within a wide temperature range of -40 ℃ to 70 ℃, and is suitable for harsh industrial environments such as severe cold and high temperature.

Protection level: It has an IP20 protection level, effectively preventing dust and foreign objects from entering, and protecting internal circuit components.

Core functions

High speed data acquisition: The digital input channel of NU8976A can quickly collect status signals from external devices, such as sensor on/off signals, button operation signals, etc. Through advanced signal processing technology, instantaneous changes in signals can be accurately captured, ensuring the timeliness and accuracy of data acquisition, and providing reliable basis for real-time control of the system.

Precise output control: The digital output channel can accurately control the start stop, operation status switching, and other operations of external devices according to system instructions. With stable output driving capability and fast response speed, it can accurately control various actuators such as solenoid valves, motor drivers, etc., achieving precise operation of industrial equipment.

Flexible communication interaction: With the help of Ethernet and RS-485 communication interfaces, as well as various industrial communication protocols, NU8976A can efficiently exchange data with controllers such as PLC, DCS, and other intelligent devices. Support master-slave mode communication, facilitate network configuration in complex industrial automation networks, and achieve collaborative work between devices.

Fault diagnosis and status monitoring: Equipped with a comprehensive self diagnostic function, it can monitor the working status of the module itself and the signal situation of the input and output channels in real time. When channel faults, communication abnormalities, and other issues are detected, alarm signals can be promptly issued and the fault information can be uploaded to the control system through the communication interface, making it easier for maintenance personnel to quickly locate and solve problems.

Working principle

When the digital signal of an external device is connected to the input channel of ABB NU8976A, the signal first passes through the input buffer circuit for isolation and level conversion to ensure the stability and compatibility of the signal. The converted digital signal is transmitted to the logic processing unit inside the module, which encodes and processes the signal before sending the data to the connected controller or other device through a communication interface.

When the module receives output control instructions from the controller, the communication interface receives data and transmits it to the logic processing unit. After decoding and analyzing the instructions, the logic processing unit controls the output driving circuit to output corresponding level signals according to the instruction requirements, driving the external actuator to act. Throughout the entire working process, the power management circuit inside the module provides stable power supply for each functional module, while the clock circuit ensures the timing accuracy of data processing and communication, ensuring efficient and stable operation of the module.

Key advantages

High performance and high reliability: Adopting advanced chip and circuit design, it has high-speed data processing and transmission capabilities, and can operate stably in complex industrial environments. After rigorous testing and verification, high-quality electronic components are selected to have excellent electromagnetic interference resistance and environmental adaptability, effectively reducing equipment failure rates and maintenance costs.

Flexibility and Scalability: Rich input and output channels and support for multiple communication protocols enable it to flexibly adapt to different industrial equipment and automation system requirements. Users can easily achieve functional expansion and system upgrades by adding expansion modules or adjusting software configurations according to actual application scenarios, meeting the constantly evolving production needs of enterprises.

Convenient integration and debugging: Standardized communication protocols and interface design enable NU8976A to be quickly and conveniently integrated into existing industrial automation systems. The accompanying debugging tools and software simplify the module configuration and debugging process, lower the technical threshold, and improve system integration efficiency.

Real time and precision: The high-speed data acquisition and output control capability ensures real-time monitoring and precise control of industrial equipment, effectively improving production efficiency and product quality, and meeting the strict requirements of industrial automation for real-time and precision.

Precautions

Installation environment: It should be installed in a dry, well ventilated, non corrosive gas, and non violent vibration environment. Avoid installation in high temperature, humid, and dusty areas to prevent electronic components from being affected by moisture, oxidation, or dust blockage, which can affect module performance and lifespan. The installation location should be far away from strong electromagnetic interference sources, such as large motors, transformers, etc., to reduce the impact of electromagnetic interference on the normal operation of the module.

Power connection: Before connecting the power supply, be sure to confirm that the input power voltage is consistent with the module requirements and ensure that the power polarity is correct. It is recommended to use a stable power supply and install appropriate fuses and filtering devices in the power line to prevent power fluctuations and surges from damaging the module.

Signal connection: When connecting input and output signal cables, ensure that the cables are firmly connected to avoid virtual connections or short circuits. For long-distance signal transmission, shielded cables should be used and the shielding layer should be reliably grounded to reduce external interference. At the same time, pay attention to the level matching of the signal to prevent the input signal from exceeding the range and damaging the module.

Software operation: When configuring and programming software, strictly follow the product manual to avoid system failures or data loss caused by improper operation. Regularly backup module configuration data for quick system recovery in case of failure. Before upgrading software versions, conduct testing to ensure compatibility between the new version of software and hardware.

Similar model supplement

ABB NU8977A Digital I/O Module: Compared with NU8976A, NU8977A has increased the number of input and output channels, making it more suitable for large-scale industrial automation projects with high point requirements. In terms of communication performance, NU8977A supports more communication protocols, has stronger communication compatibility, and can meet more complex industrial network architecture requirements.

ABB NU8975A Digital I/O Module: This model focuses on low-cost and miniaturized applications, with relatively few input and output channels, but it has the basic functions of NU8976A. Suitable for small industrial automation scenarios that are cost sensitive and have relatively simple control requirements, such as local control of small production lines, automation transformation of simple equipment, etc.