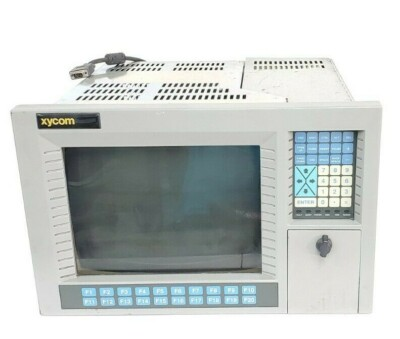

XYCOM PRO-FACE 1547 (1547-0011310130000)

Product Overview

PRO FACE XYCOM 1547 (model: 1547-0011301030000) is an outstanding industrial computer in the XYCOM series under PRO FACE. As an upgraded iteration product of the 1546 model, it inherits the advantages of its predecessor and has undergone performance optimization and functional expansion. Specially designed for harsh industrial environments, aiming to provide more efficient, stable, and intelligent computing and control solutions for industrial automation, intelligent manufacturing, process control, and other fields, helping enterprises improve production efficiency and enhance competitiveness.

Brand background

PRO-FACE has been deeply involved in the field of industrial automation for many years, always adhering to the concept of technological innovation and quality first, and committed to providing advanced products and comprehensive solutions for global industrial users. Its XYCOM series industrial computers, with reliable performance, excellent environmental adaptability, and rich functions, are widely used in many industries such as energy, manufacturing, transportation, and chemical engineering, accumulating a good reputation and market recognition, and becoming one of the trusted brands in the field of industrial automation.

Specification parameters

Interface configuration

Network interface: equipped with multiple high-speed Ethernet interfaces, supporting gigabit or even ten gigabit network communication, significantly improving data transmission speed, and enabling high-speed data exchange and remote monitoring with other devices, upper computer systems, and cloud platforms in industrial networks. At the same time, it supports multiple network protocols such as TCP/IP, UDP, HTTP, etc., making it convenient to access different types of industrial network architectures.

Serial port: With abundant serial port resources, including multiple RS-232, RS-485, and RS-422 serial ports, it can flexibly connect various industrial sensors, instruments, actuators, PLCs, and other devices to achieve device status data acquisition, control command transmission, and communication between devices, meeting the diverse serial communication needs of industrial sites.

Other interfaces: equipped with multiple USB 3.0 interfaces, supporting high-speed data transfer, facilitating data backup and exchange with external mobile storage devices, connecting to printers to print production reports, and connecting to external devices for functional expansion; At the same time, it may have video output interfaces such as HDMI and VGA, which are convenient for connecting display devices such as monitors and projectors, for monitoring screen display, operation interface display, and data visualization presentation.

Physical characteristics and environmental adaptability

Appearance design: Continuing the compact and sturdy chassis design style, while ensuring a reasonable internal hardware layout, it effectively saves installation space and is suitable for industrial environments with limited space such as factory workshops and control cabinets. The chassis is made of high-strength metal material, which has excellent resistance to mechanical collision and vibration, and can effectively protect the internal precision electronic components.

Core functions

(1) Deep control of industrial automation

High precision equipment collaborative control: As the core control center of industrial automation systems, XYCOM 1547 can simultaneously connect and control more types and larger quantities of industrial equipment, such as multi axis robots, high-precision CNC machine tools, intelligent conveyor belts, etc. By running advanced control algorithms and programs, high-precision and collaborative control of equipment is achieved, ensuring precise coordination between devices and improving production efficiency and product quality. For example, in precision electronic manufacturing production lines, the collaborative operation of multiple surface mount machines and welding robots can be precisely controlled to achieve high-speed and precise placement and welding of electronic components.

Complex process optimization management: With strong process management capabilities, it can model, monitor, and optimize complex industrial production processes. According to the preset production process and logic, coordinate the work sequence, time nodes, and parameter settings of each production link in real time, dynamically adjust production strategies to cope with abnormal situations in the production process, such as equipment failures, material shortages, etc., ensure the efficient and stable operation of the production process, reduce production costs, and improve production efficiency.

(2) Intelligent data collection and analysis

High speed collection of multi-source heterogeneous data: By utilizing rich interface resources, it is possible to simultaneously collect multi-source heterogeneous data from different types of sensors, devices, and systems, including analog data, digital data, image data, video data, etc. By using high-speed data acquisition modules and optimized data transmission protocols, real-time and accurate data collection can be achieved. The collection frequency and accuracy meet the requirements of various complex application scenarios in industrial sites, providing a reliable data foundation for subsequent data processing and analysis.

Deep data analysis and decision support: Equipped with advanced data analysis algorithms and software platforms, it can deeply mine and analyze the massive industrial data collected. By using machine learning, artificial intelligence and other technologies, functions such as equipment failure prediction, production quality trend analysis, and energy consumption optimization analysis can be achieved, providing scientific and accurate decision support for enterprise production management. For example, by analyzing equipment operation data, predicting equipment failures in advance and issuing warnings, arranging preventive maintenance, and reducing equipment downtime; By analyzing production quality data, identifying key factors that affect product quality, optimizing production process parameters, and improving product qualification rates.

(3) Efficient communication and networking

Seamless integration of industrial networks: Supports comprehensive industrial communication protocols, in addition to common protocols such as Modbus, Profibus, Ethernet/IP, it may also support emerging industrial Internet of Things protocols such as OPC UA and MQTT, enabling seamless communication and integration with different manufacturers and types of industrial equipment and control systems, achieving interconnectivity of industrial networks. It can easily connect to various network architectures such as industrial Ethernet and industrial fieldbus, and build an integrated industrial automation communication network.

Remote intelligent monitoring and operation: With the help of high-speed network communication functions, operators and technicians can view the real-time operation status, production data, alarm information, etc. of industrial field equipment through remote monitoring centers, mobile terminals, and other devices, achieving remote intelligent monitoring of industrial production processes. At the same time, technicians can perform software upgrades, parameter adjustments, fault diagnosis and repair operations on XYCOM 1547 through remote connections, reducing on-site maintenance workload, improving equipment maintenance efficiency, and reducing enterprise operation and maintenance costs.

Working principle

XYCOM 1547 in industrial control systems first receives data signals from sensors, equipment, and other systems on the industrial site through various interfaces. These signals are preprocessed through interface circuits such as signal conditioning and level conversion before being transmitted to high-performance processors. The processor performs operations, analysis, and processing on input data based on pre written control programs, algorithms, and data analysis models, generating corresponding control instructions, analysis results, and decision recommendations.

Control instructions are transmitted to actuators such as motors, valves, relays, etc. through output interfaces to achieve precise control of industrial equipment; The analysis results and decision recommendations are transmitted to the upper computer system, monitoring center, or mobile terminal through a network communication interface for operators and managers to view and make decisions. Throughout the entire work process, memory is used to store running programs, temporary data, and cache partially processed data, while storage devices are used for long-term storage of important information such as system programs, user profiles, and historical data. At the same time, XYCOM 1547 interacts with other devices in the industrial network in real-time through network communication modules, obtains system status information, and feeds back its own operating status to the upper computer or monitoring system, achieving closed-loop control and intelligent management of industrial production processes.