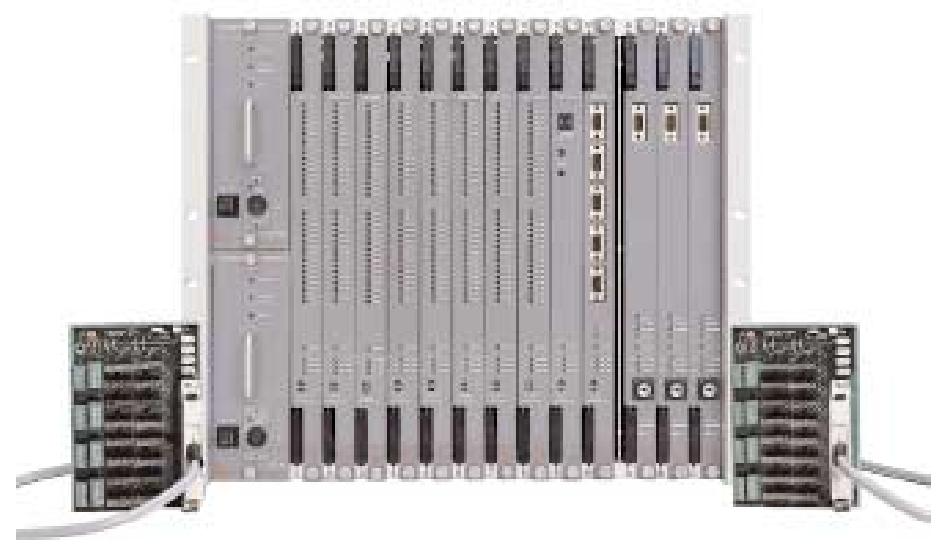

AC 800F Freelance 200 control system

Base unit technical data

Processor and memory: Intel 80960HT25/75 32-bit RISC Super Scalar microprocessor up to 150 MIPS. 4 MB static RAM, 4 MB Flash-EPROM, 16 K internal CPU cache RAM, 16 Kbit Serial EEPROM for PM 802F and 16 MB synchronous dynamic RAM, 8 MB Flash-EPROM, also with 16 K internal CPU cache RAM and 16 Kbit Serial EEPROM for PM 803F. The PM 803F has 16 MB of synchronous dynamic RAM, 8 MB of Flash-EPROM, 16 K of internal CPU cache RAM and 16 Kbit serial EEPROM.

Data Processing and I/O: 1000 instruction execution time, less than 1.0 ms for binary and 16-bit arithmetic, less than 2 ms for fixed-point arithmetic, and less than 1.5 ms for 32-bit arithmetic I/O scan cycle times are configurable, depending on fieldbus module capabilities.

Power supply and physical specifications: The PM 802F base unit has a maximum power consumption of 6.3 W, the PM 803F 7.8 W. The power supply is available in 115 – 230 V AC (SA 801F/SA 811F) and 2 x 24 V DC (SD 802F/SD 812F). Weight max. 5 kg (fully assembled), dimensions W 239 mm, H 202 mm, D 164 mm.

Power supply module technical data

x 24 V DC (allowable range 19.2 – 32.5 V DC), SD 802F outputs 5 V DC / 5 A and 3.3 V DC / 5 A, SD 812F outputs 5 V DC / 5.5 A and 3.3 V DC / 6.5 A.

Other parameters: SA 801F rated input power 48 VA, SA 811F 63 VA; SD 802F rated input power 31 W, SD 812F 41 W. All of them are equipped with a power failure backup energy of more than 20 ms, short-circuit protection and current limiting function, SA 801F/SA 811F current limiting is about 6 A and 7.5 A respectively, SD 802F/SD 812F current limiting is about 6 A and 7.5 A respectively, SD 802F/SD 812F current limiting is about 5 V DC / 5 A and 3.3 V DC / 5 A respectively. The SA 801F/SA 811F have current limits of approx. 6 A and 7.5 A, the SD 802F/SD 812F have current limits of approx. 6 A and 7.5 A.

Ethernet Module Technical Specifications

Communication and power supply: IEEE802.3 compliant, transmission rate 10 MBit/s, 32-bit data bus, direct memory access, CPU overhead less than 4%, power consumption 2.8 W and 2.0 W for EI 801F/EI 811F, 3.0 W for EI 802F without transceiver power supply, 6.2 W with transceiver, etc.

Interface and Storage: Different interface types correspond to different physical interfaces, such as 10Base2 coaxial cable interface for EI 801F/EI 811F, and AUI interface for commercial transceivers for EI 802F/EI 812F. Some modules have battery backup function, and different modules have different RAM and real-time clock buffer time under different base unit configurations.

Other module specifications

Fieldbus modules: CAN-3 module FI 810F up to 1 MBd, power consumption 1.6 – 2.6 W; Serial module FI 820F up to 38.4 KBaud, power consumption 1.6 – 2.6 W; Profibus module FI 830F up to 12 MBd, power consumption 2.8 W depending on the communication cycle time when active; FF 830F up to 12 MBd, power consumption 2.8 W depending on the communication cycle time. FI 830F with transmission rates up to 12 MBd and power consumption depending on the communication cycle time in the active state 2.8 W; FF/HSE module FI 840F with transmission rates of 10 Mbit/s or 100 Mbit/s and power consumption of 1.4 – 2.1 W.

Battery modules: AM 801F provides backup for PM802F, AM 811F for AC 800F. The power consumption is about 0.25 W and 0.28 W respectively, and the batteries are 3.6 V Li-Ion, 950 mAh, with different RAM and real-time clock buffer times for different base unit configurations.

Application Scenarios

Industrial automated production line control: In industrial automated production lines such as automotive manufacturing and electronic equipment production, the AC 800F can be connected to a variety of fieldbus devices. By connecting robots, sensors and actuators through PROFIBUS – DP, the AC 800F achieves precise control of material handling, parts processing, product assembly and other aspects of the production line. Its high-speed data processing capability and configurable I/O scanning cycle can ensure the efficient and stable operation of the production line and improve production efficiency and product quality.

Process industry monitoring and control: In the chemical, petroleum, power and other process industries, the AC 800F is used for real-time monitoring and control of key parameters such as temperature, pressure, flow rate, etc. in the production process. Using its support for a variety of fieldbus types, such as Modbus, Foundation Fieldbus H1, etc., connected to various types of transmitters, control valves and other field equipment, to achieve accurate regulation of the production process. In chemical production, through real-time monitoring and control of reactor temperature and pressure, it ensures that chemical reactions are carried out under safe and efficient conditions, avoiding production accidents and improving product yields.

Smart factory construction: With the development of Industry 4.0 and smart manufacturing, AC 800F plays an important role as one of the core control equipment of smart factory. It integrates with other information systems in the factory to achieve real-time collection, analysis and sharing of production data. With the help of Ethernet communication and unified database, it transmits on-site equipment data to the management system, providing a basis for production decision-making. In the intelligent warehousing and logistics system, AC 800F controls the automated equipment for storing, sorting and transporting goods, improving logistics efficiency and reducing operating costs.

Critical Systems with High Reliability Requirements: The AC 800F’s redundant design plays an important role in areas that require high system reliability, such as aerospace and medical device manufacturing. Controller redundancy and Profibus line redundancy ensure that the system can operate normally in the event of a partial equipment failure. In aerospace manufacturing, where the precision of component processing and the stability of equipment operation are critical, the AC 800F’s redundancy feature ensures that the production process is not interrupted, avoiding production delays and quality problems caused by equipment failure.