Product Core Overview

1. Basic positioning and applicable scenarios

Function positioning: Based on microprocessor, PWM AC driver is used to control the speed of three-phase motors. It adapts to various load requirements through adjustable voltage/frequency (V/Hz) or sensorless vector control, especially suitable for industrial scenarios with high requirements for torque and speed accuracy (such as fans, pumps, conveyors, etc.).

Power and voltage range: The power covers 0.37-448kW (0.5-600 horsepower) and supports three voltage levels -200-240V AC, 380-480V AC, and 500-600V AC, which can meet industrial power supply standards in different regions.

Compatibility advantage: with Allen Bradley SMC ™、 SMP ™ Power products, 1305 drivers, 1336 IMPACT ™ And 1336 FORCE ™ Vector control drivers share control interfaces and communication options to reduce system design, integration, and maintenance costs.

2. Core design highlights

Structural design: Flat construction reduces internal cables and connectors, improving reliability; Laminar busbar design reduces internal inductance, minimizes buffering losses, and optimizes IGBT performance; Removable Human Machine Interface (HIM) simplifies programming and operation.

Heat dissipation and protection: optimize thermal management through infrared testing to reduce hotspots; Supports IP20 (NEMA Type 1, Universal), IP54 (NEMA Type 12, Dustproof), IP65 (NEMA Type 4, Waterproof and Dustproof) protection levels, suitable for different industrial environments.

Global adaptation: Compliant with international standards such as UL, CSA, EN, IEC, VDE, etc., equipped with DC cooling fans, no need for transformers and voltage taps, supporting global use.

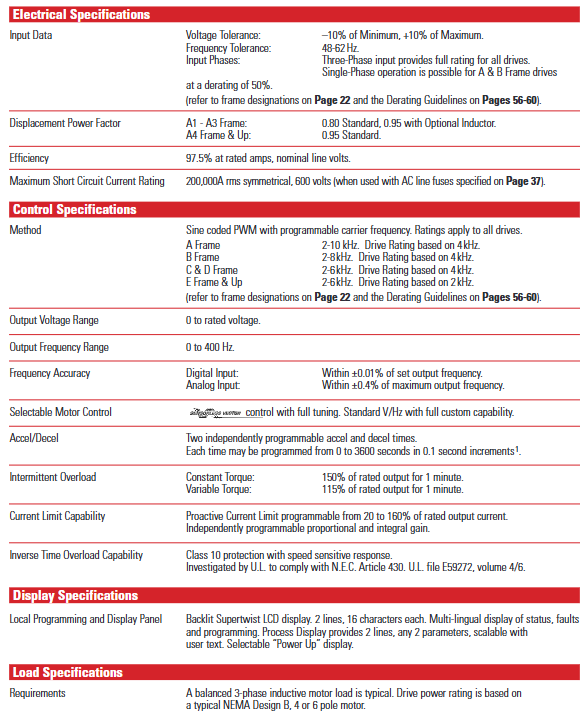

Key specification parameters

1. Electrical protection specifications

The protection threshold of drivers with different voltage levels varies, and the core protection parameters are shown in the following table:

Protection project: 200-240V driver, 380-480V driver, 500-600V driver

AC input overvoltage trip 285V AC 570V AC 690V AC

AC input undervoltage trip 138V AC 280V AC 343V AC

Bus overvoltage tripping 405V DC 810V DC 1013V DC

Bus undervoltage tripping 200V DC 400V DC 498V DC

Driver overcurrent trip (hardware) 180-250% rated current 180-250% rated current 180-250% rated current

Grounding fault tripping output terminal phase to phase grounding detection output terminal phase to phase grounding detection output terminal phase to phase grounding detection

In addition, the drive also has fault detection and trip protection functions such as overheating, encoder loss, load loss, and single-phase operation, and supports 6 types of drive alarm and fault reset inputs.

2. Environment and operating specifications

Environmental conditions: Maximum altitude of 1000m (without capacity reduction), exceeding this limit requires reference to the capacity reduction guidelines; The working temperature IP00 (open type) is 0-50 ℃, and IP20/54/65 is 0-40 ℃; Storage temperature -40-70 ℃; Relative humidity 5-95% (no condensation), shock resistance 15G peak (11ms), vibration resistance 0.006 inches displacement (1G peak).

Output performance: Output frequency range 0-400Hz, frequency accuracy (digital input) ± 0.01% set value, (analog input) ± 0.4% maximum value; Acceleration/deceleration time can be independently programmed (0-3600 seconds, 0.1 second increments); The overload capacity of constant torque load for 1 minute is 150% of the rated output, and the overload capacity of variable torque load for 1 minute is 115% of the rated output.

Core functional characteristics

1. Motor control function

Sensorless vector control: Excellent torque performance at low speeds (as low as 15rpm), with a constant torque speed range of 120:1 and a starting/accelerating torque of up to 250%. It supports motor parameter self-tuning (requires input of motor nameplate values) and is suitable for fast acceleration requirements of low inertia loads.

V/Hz control: fully programmable mode, supporting startup lifting, operation lifting, and slope adjustment for lifting, suitable for multi motor co drive scenarios (such as different power motors sharing one driver).

Slip compensation: Automatically increase the output frequency according to the load, compensate for the rotor slip of the induction motor, with a typical speed adjustment accuracy of 0.5%, to avoid speed drop caused by increased load.

Flying Start function: It can detect the speed and direction of the rotating motor without the need for an encoder, start from the current speed and transition to the commanded speed, and adapt to scenarios such as fans and pumps that require “load start”.

2. Process control and protection

Process PI controller: Through proportional (KP) and integral (KI) gain adjustment, combined with feedback scaling, error reversal, and output clamping, it achieves speed closed-loop control based on feedback signals (such as pressure and flow), supporting “automatic/manual” switching and smooth transition.

Braking function: Supports DC injection braking (programming time 0-90 seconds), dynamic braking (requires an external braking unit), and continuous holding braking (sets the “Ramp to Hold” mode, outputs the set current at zero frequency until the start command or enable is disconnected).

Power outage response: Supports two modes of “line loss fault enable/disable”. When there is a line loss, the operation is maintained through DC bus energy storage. When the bus voltage drops to 85% of the rated value, the output is turned off. After power is restored, it can be restarted through methods such as flying start and detecting motor voltage.

3. Monitoring and Diagnosis

Real time monitoring: Display output current, voltage, frequency, temperature and other parameters through HIM’s backlight ultra twisted LCD (2 lines x 16 characters), supporting multilingual switching; The “Process Display” mode allows customization of display units and parameter combinations (such as “121.6 In/min” and “2.7AmPs”).

Fault recording and diagnosis: Cache the last 4 faults and automatically start the fault diagnosis program upon startup; When there is a malfunction, display a prompt in _plain language_ (such as “Undervolt Fault” or “Overtemp Fault”) and report the status through the HIM or SCANPort communication port.

Installation and Wiring Guide

1. Installation requirements

Size and weight: There are significant differences in the size of drivers with different frames (A1-G). Taking IP20 (NEMA Type 1) as an example, A1 frame size is 215.9 × 290.0 × 160.0mm (width × height × depth), weighing 4.31kg; G frame size is 635.0 × 2324.1 × 508.3mm, weighing 453.6kg (please refer to the specific frame size table).

Installation spacing: At least 152.4mm (6 inches) of ventilation space should be reserved on both sides and the back; The F-frame drive requires additional side/back space, and when the open drive is installed in the user housing, it needs to be equipped with two 725 CFM fans (BPR series requires fans of 450 CFM or above).

2. Wiring specifications

Power wiring (TB1 terminal): input terminals R (L1), S (L2), T (L3), output terminals U (T1), V (T2), W (T3), DC bus terminal+DC/- DC, grounding terminals PE (protective ground), TE (shielding ground); 75 ℃ copper wire is required, with different wire diameters for different frame terminals (maximum 5.3mm ²/10AWG for A1-A4 frame, maximum 303.6mm ²/600MCM for G frame), and torque must comply with specifications (such as 1.81N/m/16lb in for A1-A4 frame).

Control and signal wiring:

Analog I/O: Standard configuration supports 0-10V/0-20mA input (single ended non isolated), optional LA series isolation card (such as LA2 dual isolated input, LA3 dual isolated output), shielding layer needs to be connected to TE terminal.

The digital I/O: TB3 terminal supports 115V AC/24V AC/DC/TTL level input and can be programmed with functions such as start, stop, reverse, and preset speed selection; The output contacts (CR1-CR4) support 115V AC/30V DC, 5A resistive/2A inductive loads.

Encoder wiring: Supports 5V DC/8-15V DC line driven encoder (orthogonal or pulse signal), maximum input frequency 250kHz, single ended/differential signal can be used, and the shielding layer is connected to the TE terminal.

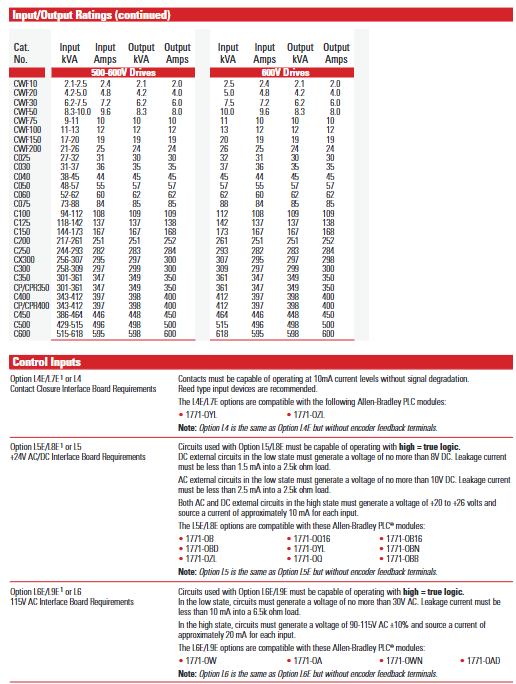

Selection and Configuration

1. Selection Guide

Model interpretation: The complete model format is “1336F-XXXXXX-XX”, such as “1336F-B020-AA”, where “B” represents the voltage/power code (460V, 20HP), “020” represents the power level, and “AA” represents the protection level (IP20/NEMA Type 1).

Load adaptation: The selection of constant torque (CT) and variable torque (VT) loads needs to be distinguished, for example, the 460V B020 model, CT rated 20HP, VT rated 25HP; the corresponding model needs to be selected according to the actual load type (such as CT for conveyor belt and VT for fan).

Option configuration: Supports factory pre installation or on-site installation options, such as communication cards (GM1 single node RIO, GM5 DeviceNet), control interface cards (L4 contact closed, L5 24V AC/DC), HIM (HA1 analog potentiometer, HJ2 digital potentiometer), braking units, reactors, etc.

2. Capacity reduction guide

When the operating conditions of the drive exceed the rated range, it is necessary to reduce the capacity. The core scenarios for reducing the capacity include:

Altitude: When it exceeds 1000m, the capacity decreases by about 6% for every 1000m increase (refer to Figure AD).

When the ambient temperature exceeds 40 ℃, the capacity will decrease by about 2% for every 1 ℃ increase (refer to Figure A-AC).

Carrier frequency: When it exceeds 4kHz (some models are 2kHz), the amplitude should be increased and the capacitance should be reduced according to the frequency (such as reducing the capacitance by 10% at 6kHz).

Fault handling and maintenance

1. Common faults and troubleshooting

The document lists more than 40 types of fault codes, and the core faults and their handling methods are as follows:

Fault code, fault name, cause analysis, and handling suggestions

04 Under voltage fault: Input voltage too low, bus capacitor fault, power failure. Check input voltage, replace capacitor, and confirm power stability

05 Overvoltage fault: Input voltage too high, brake unit fault, high load regeneration energy. Check input voltage, repair brake unit, and increase regeneration resistance

07 Overload fault: Excessive motor load, motor stalling, improper overload parameter settings. Reduce load, investigate the cause of stalling, and reset the overload current

08 Overheating fault: Cooling fan failure, high ambient temperature, blocked air duct. Replace the fan, improve ventilation, and clean the air duct

13. Grounding fault output terminal short circuit to ground, motor insulation damage. Check the output circuit and test the motor insulation resistance

2. Preventive maintenance

Regular inspection: Check the operation status of the cooling fan and the cleanliness of the air duct every week; Check the tightness of wiring terminals and the insulation layer of cables every month; Quarterly testing of bus voltage and output current balance.

Maintenance records: Use HIM to view parameters such as “Elapsed Run Time” and “Motor OL Count” to predict component lifespan (such as fan lifespan of approximately 20000 hours).

Leave a comment

Your email address will not be published. Required fields are marked *